Box-type substation

A box-type substation and substation technology, applied in the field of substations, can solve the problems of leakage, infiltration, electric shock and other problems in substations, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

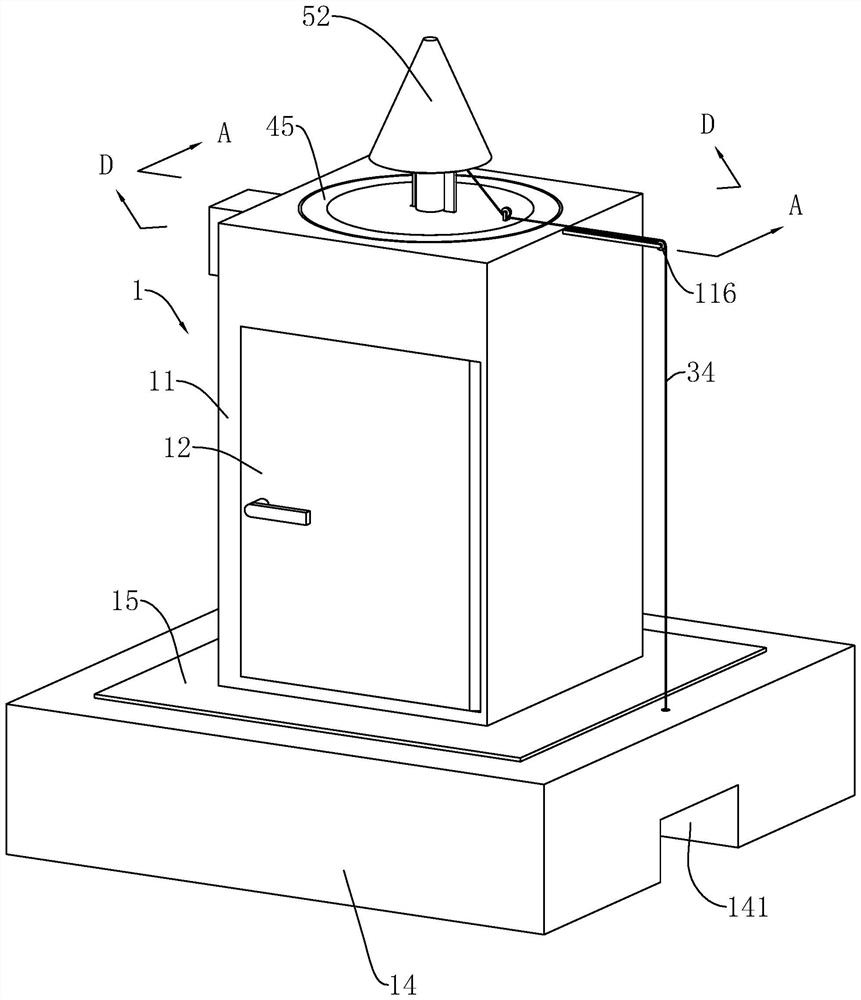

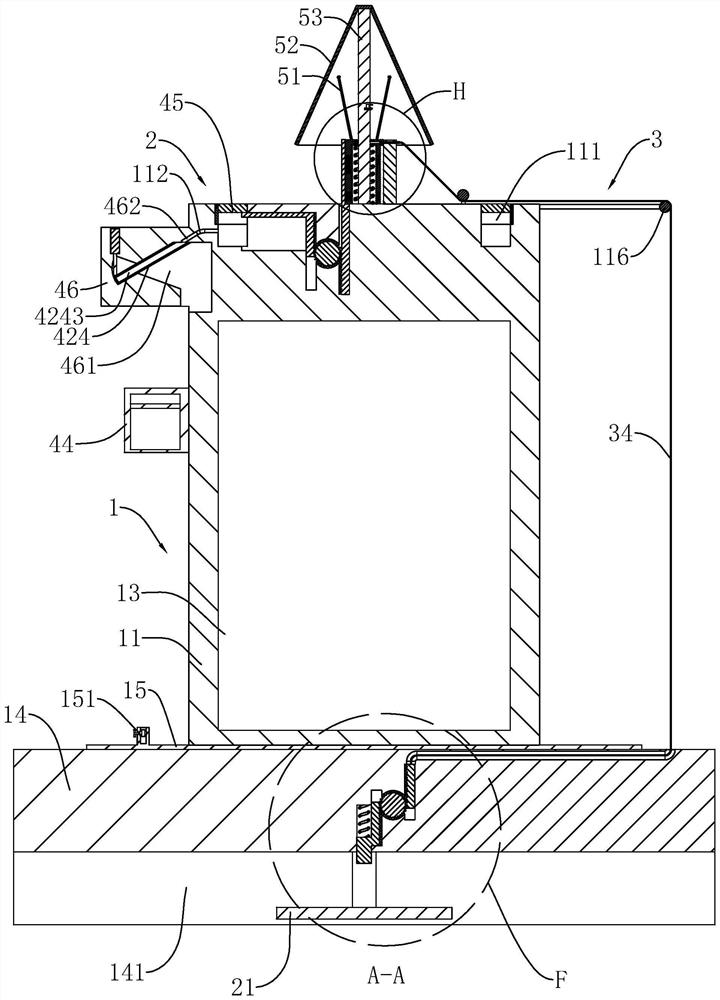

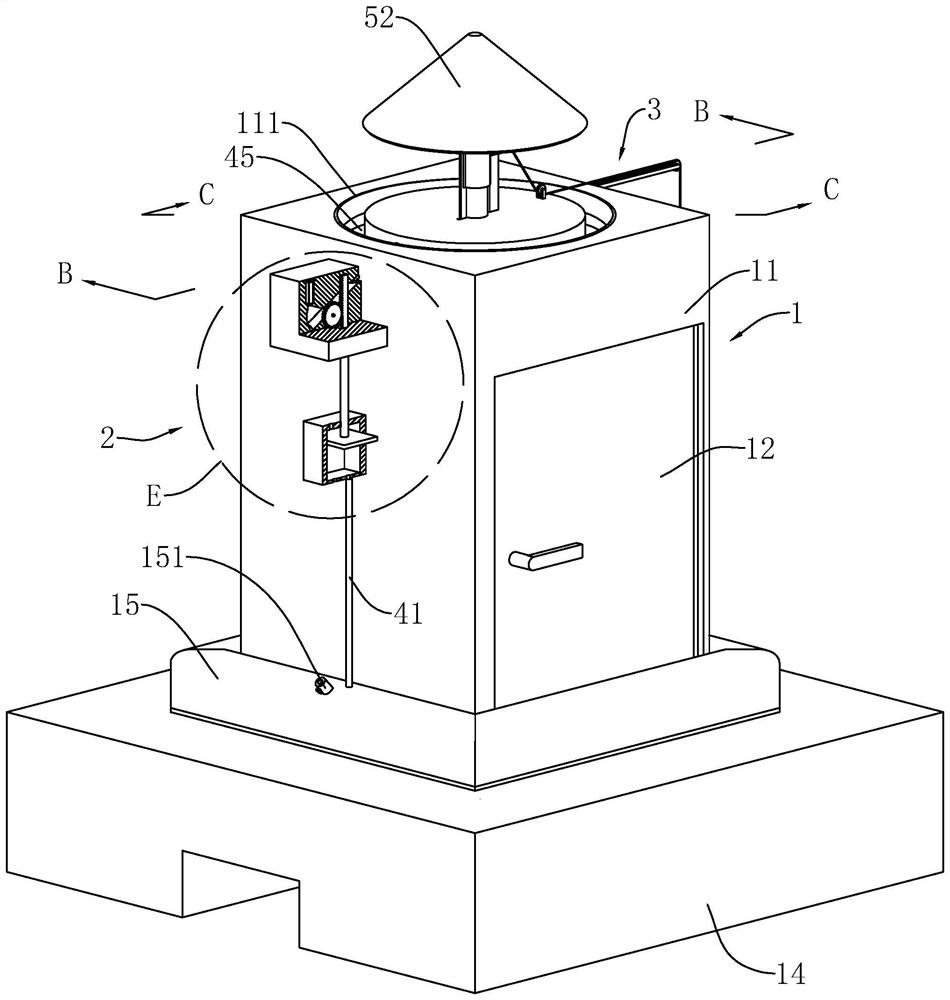

[0042] Attached to the following Figure 1-11 This application will be described in further detail.

[0043] The embodiments of the present application disclose a box-type substation.

[0044] refer to figure 1 , figure 2 , a box-type substation in this embodiment includes a substation body 1 , a base 14 , an inflation device 2 and an inflatable air bag 15 . The substation body 1 includes a box body 11 with an accommodating cavity 13 and a door panel 12 hinged on the box body 11. The accommodating cavity 13 is used for placing various equipment such as transformers. When the airbag 15 is not filled with gas, the airbag 15 is laid flat on the top surface of the base 14 , the airbag 15 is located between the base 14 and the box body 11 , the box body 11 is fixed on the base 14 by the airbag 15 , and the airbag 15 is on the box body 11 . The projection on the box body 11 is completely covered, and only the part of the airbag 15 around the substation body 1 can be inflated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com