Tail end TCP (Transmission Control Protocol) transfer method of industrial robot

A technology of industrial robots and transfer methods, applied in the field of TCP transfer at the end of industrial robots, can solve problems such as low precision, long operation time, and complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

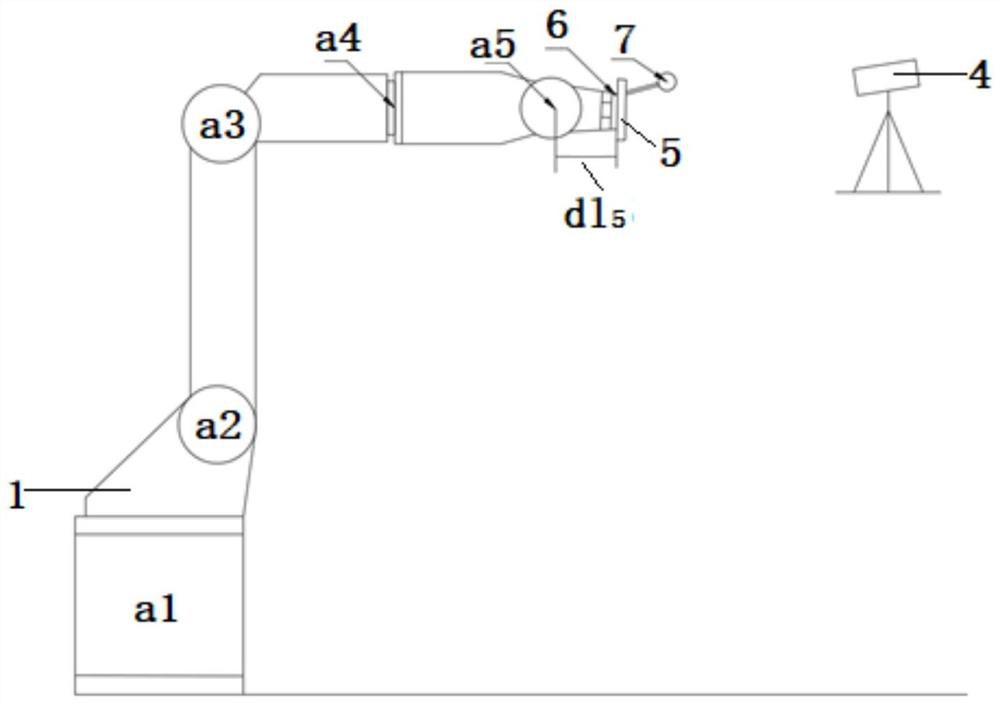

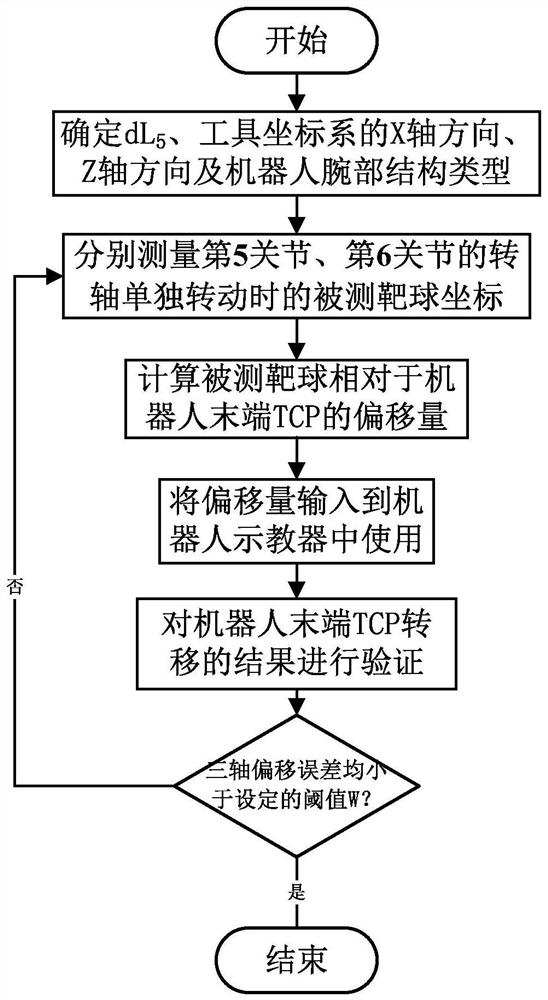

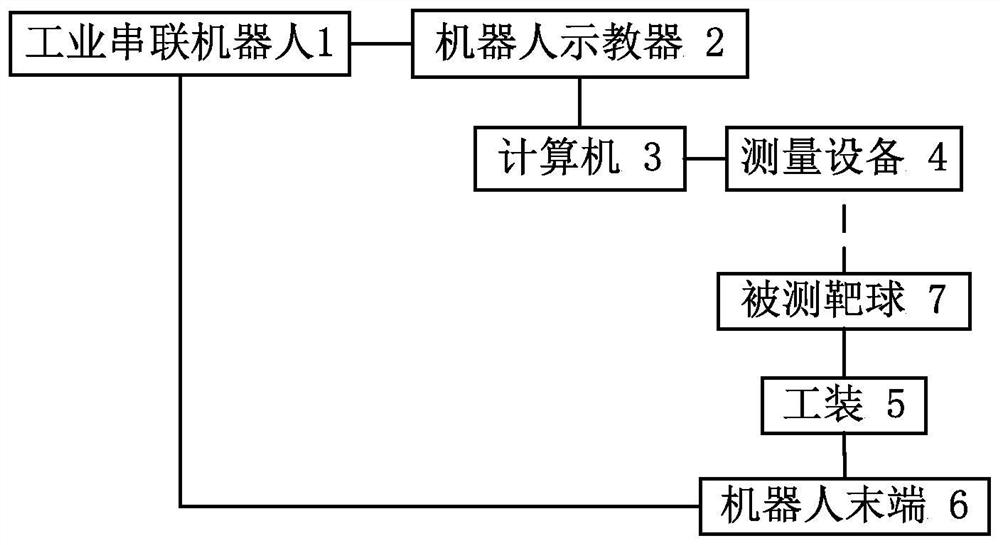

[0045] like figure 1 , image 3 The illustrated embodiment is a TCP transfer method at the end of an industrial robot, including an industrial serial robot 1, a robot teach pendant 2, a computer 3, a measuring device 4, and a target ball 7 to be measured mounted on the robot end 6 through a tooling 5; The industrial serial robot and the robot teach pendant are connected to the data, and the computer is respectively connected to the robot teach pendant and the measuring equipment; such as figure 2 shown, including the following steps:

[0046] Choose a suitable place to place the measurement equipment around the working space of the industrial tandem robot under test to ensure that the effective measurement range of the test equipment is sufficient to cover the working space of the robot under test.

[0047] 1-1, the industrial serial robot is a 6-axis robot, figure 1 The a1-a5 in the above are the 1st to 5th joints of the robot, and the 6th joint is the end of the robot; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com