Wear-resistant anti-aging floor material and production device

A technology of floor materials and production equipment, which is applied in the direction of buildings, floors, insulation layers, etc., can solve the problems of secondary processing of floors, etc., and achieve the effects of easy sales, increased wear resistance and anti-skid performance, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below with reference to the accompanying drawings.

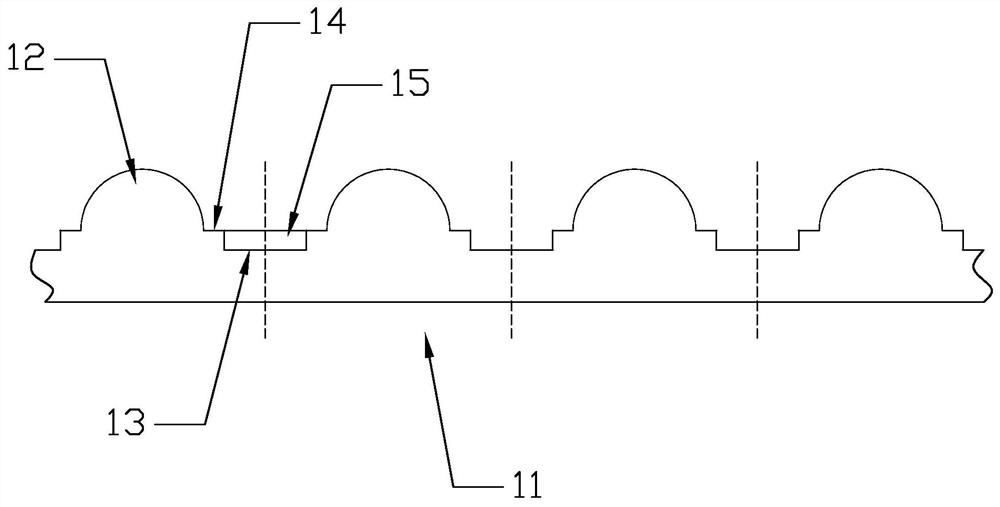

[0043] as attached figure 1 As shown in the figure, a wear-resistant anti-aging floor material includes a floor body 11, and the upper end surface of the floor body 11 is regularly distributed with a number of lateral wear-resistant protrusions 12, and the two ends of each wear-resistant protrusion 12 are regularly distributed. They extend to both sides of the floor body 11 respectively; a downwardly concave recessed groove 13 is provided between the adjacent wear-resistant protrusions 12, and the notch of the recessed groove 13 and the wear-resistant protrusions 12 are extended laterally. face 14 is connected;

[0044] The cross-sectional shape of the wear-resistant protrusion 12 is a semicircle;

[0045] An anti-aging filling layer 15 is pasted in the recessed groove 13; the anti-aging filling layer 15 is EPDM particles.

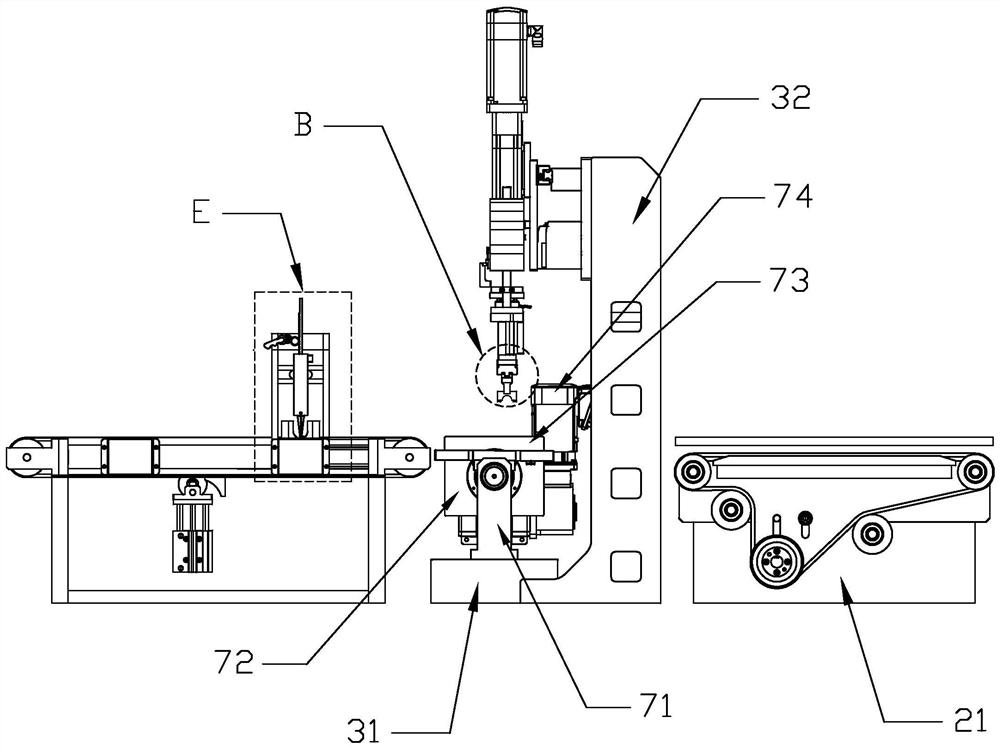

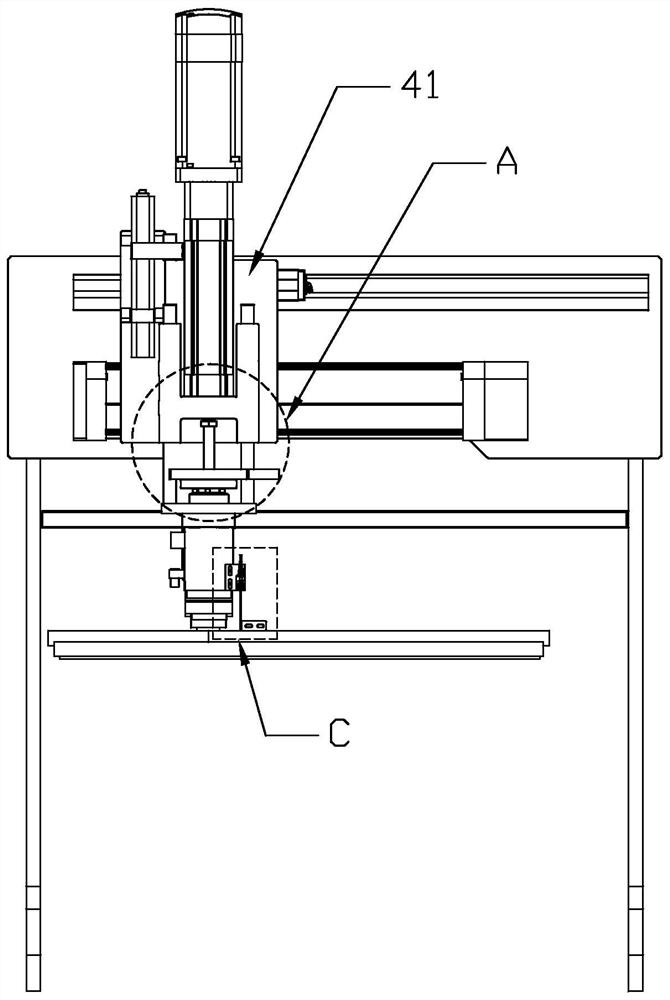

[0046] as attached Figures 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com