Quick-insertion cable joint for underwater butt joint

A technology for underwater docking and cable joints, which is applied in the direction of gas-filled/oil-filled cable accessories, climate change adaptation, etc., and can solve the problems of incomplete cable docking, high qualifications, experience and technical level, unfavorable cable use, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

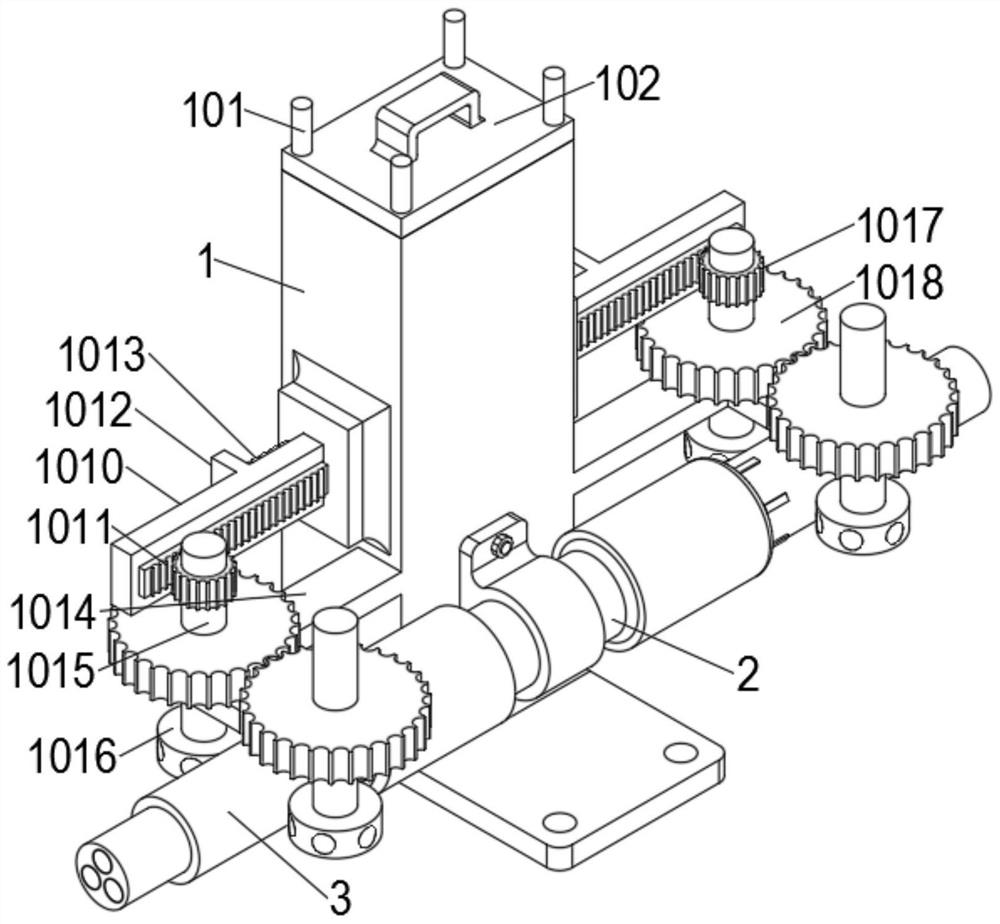

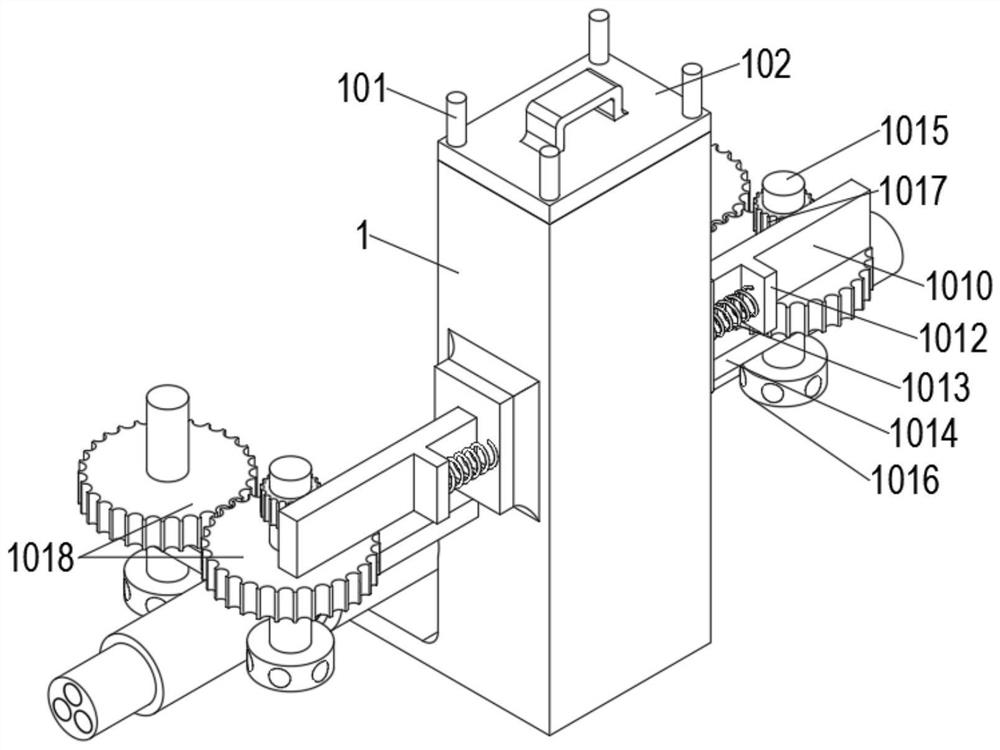

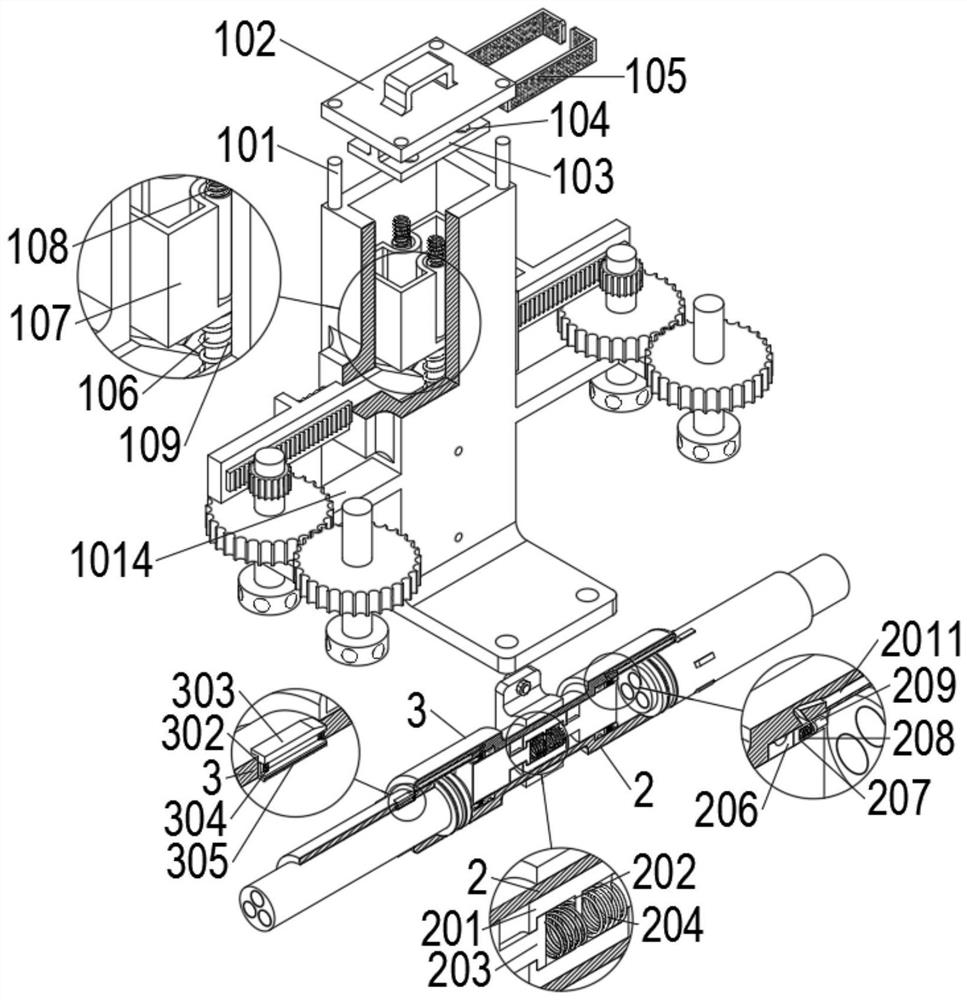

[0057]Example: please refer to Figure 1 to Figure 10 :

[0058] The invention proposes a quick-installed cable joint for underwater docking, including: a main body 1, a butt joint 2 is installed on the front side of the main body 1 by means of bolts; the left and right ends of the butt joint 2 are slidably installed with a conveying cylinder 3; The outer circumferential wall of the cylinder 3 is provided with a carrier groove 301; the inner end of the conveying cylinder 3 is provided with an elastic rubber B306; the inner side of the elastic rubber B306 is provided with a butt ring B307; The inner left and right ends of 2 are provided with elastic rubber A206; the outer end of the elastic rubber A206 is provided with a butt ring A207.

[0059] Furthermore, according to embodiments of the present invention, such as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, vertical rods 101 are provided at the top four corners of the main body 1; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com