Method for on-site and real-time collection and processing of geometric parameters of railway lines

A technology of geometric parameters and lines, which is applied in the field of on-site and real-time collection and processing of geometric parameters for railway lines, can solve the problems of limited number of spotlights, limited use, manufacturers can hardly afford long and expensive certification processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Preferred embodiments of the proposed invention are described below with reference to the accompanying drawings.

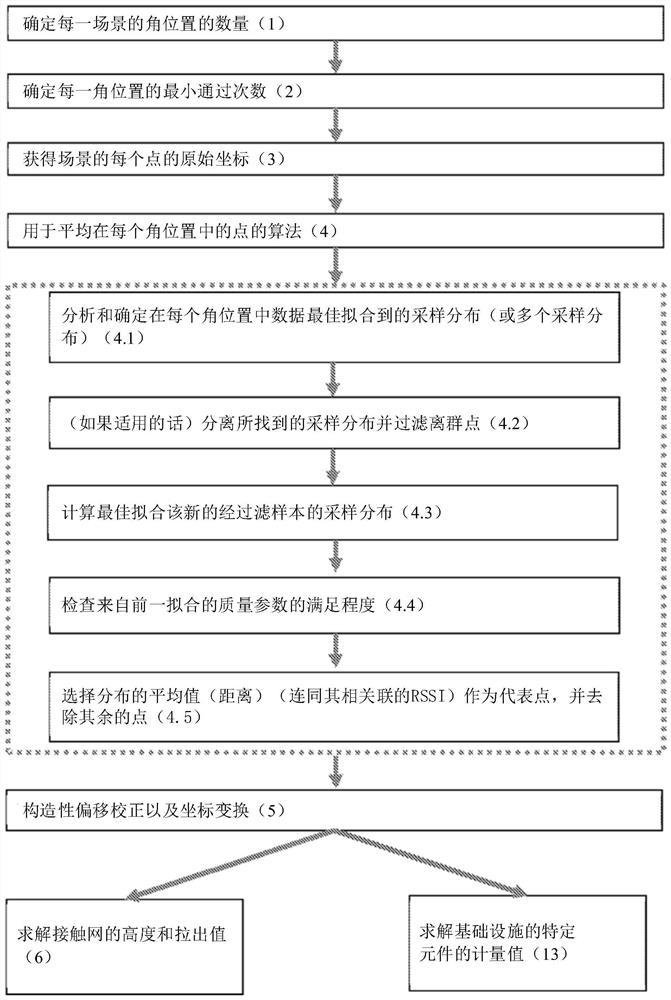

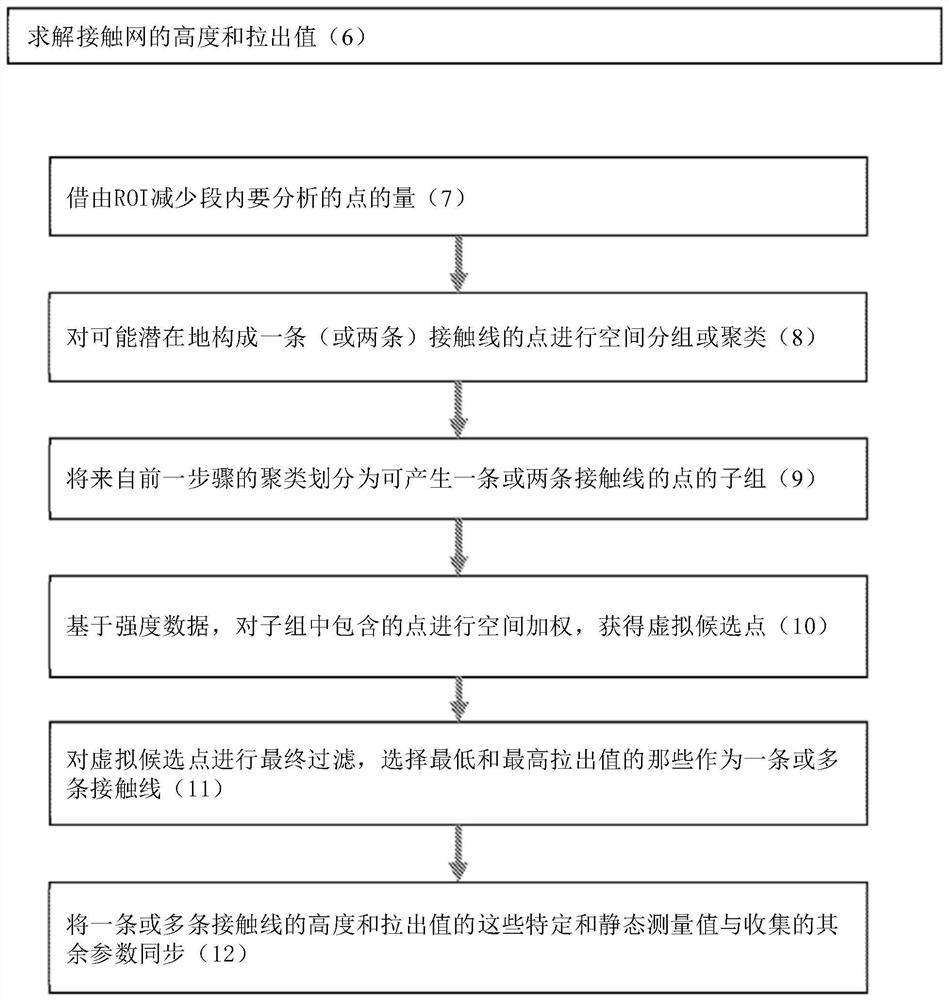

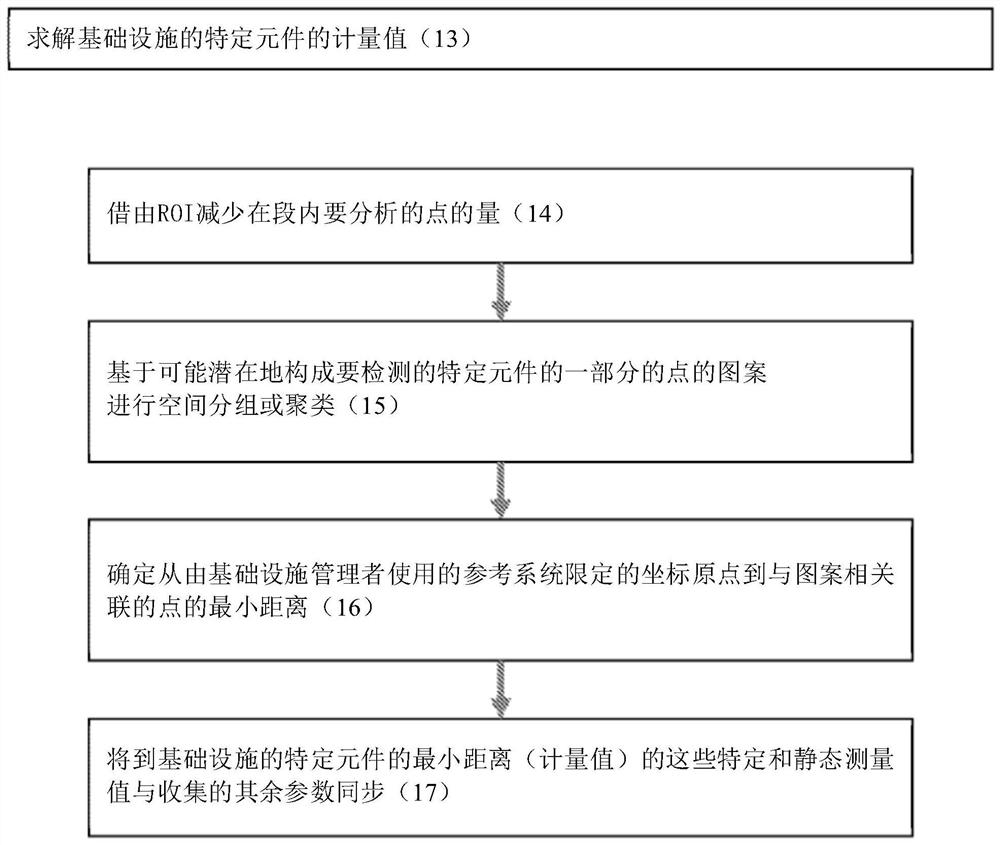

[0067] The method object of the present invention for the on-site and real-time collection and processing of geometric parameters comprises the following steps:

[0068] - Determine the number (1) of angular positions for each scenario required to solve for a particular element of the railway infrastructure, based on a study of the causal relationships of these environments. This minimum number of angular positions will determine the laser scanner model used and its configuration parameters (in a specific but non-limiting way: field of view, angular resolution and beam divergence).

[0069]- Determine the minimum number of passes (2) for each corner position to ensure repeatability of the measurements. This value will be set by studying the evolution of the most representative central and scatter statistics of the point cloud types obtained in the scene of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com