Gravity reset type anti-skid device and molten aluminum transfer system and method

An anti-skid device and resetting technology, which is applied in the casting field of aluminum alloy parts, can solve problems such as sliding and falling, and achieve the effects of easy installation, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

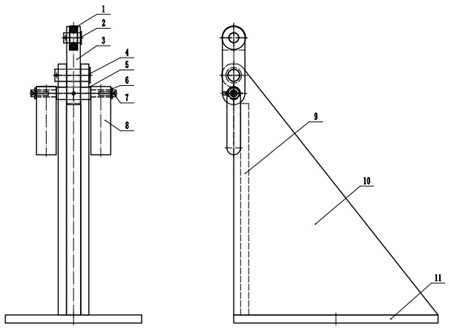

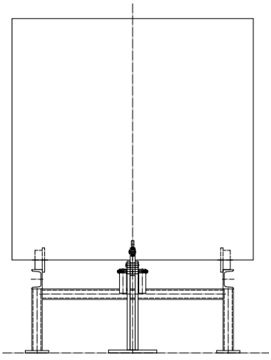

[0026] Attached below figure 1 Illustrating Embodiment 1 of the present invention:

[0027] A gravity reset type anti-skid device, comprising a bearing 1, a bearing pin 2, a swing arm 3, a swing arm shaft 4, a counterweight shaft 5, a gasket 6, a bolt 7, a counterweight block 8, a baffle 9, and a vertical plate 10 , the bottom plate 11, two vertical plates 10 are welded on the bottom plate 11, the top of the vertical plate 10 is processed with pin holes for installing the swing arm shaft 4, and the side of the top of the vertical plate 10 is processed with a concave semicircle for accommodating Counterweight shaft 5; one end of the swing arm shaft 4 and the bearing pin shaft 2 is a shaft shoulder and the other end has a cotter pin mounting hole, and the swing arm shaft 4 and the bearing pin shaft 2 are positioned by using the shaft shoulder and the installation cotter pin; the swing arm shaft 4 and the bearing pin shaft 2; 3 is installed on the vertical plate 10 through the s...

Embodiment 2

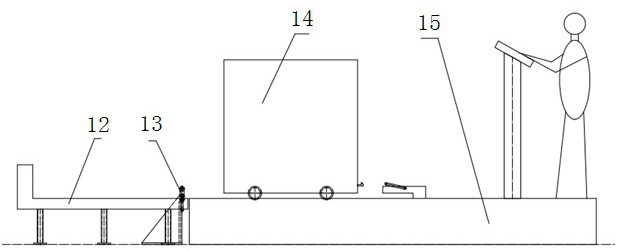

[0029] A liquid aluminum transfer system, using any of the above-mentioned gravity reset type anti-skid devices, also includes a work station 12, a crucible furnace 14, and a transfer vehicle 15, and the work station 12 is used to park the crucible furnace 14 for degassing. , slag removal, weighing and other operations, the crucible furnace 14 is used to store and transfer molten aluminum, and there are wheels at the bottom and hooks at the back. There is a push-pull device on the car 15, which is used to pull the crucible furnace 14 to the transfer car 15 or push the crucible furnace 14 to the station 12. The gravity reset type anti-skid device 13 is in a natural state and the swing arm 3 is in a vertical state. The top of the arm 3 is higher than the bottom surface of the crucible furnace 14 .

Embodiment 3

[0031] A transfer method of an aluminum liquid transfer system, characterized in that it comprises the following steps:

[0032] Step 1: When the transfer vehicle 15 pushes out the crucible furnace 14 to the station 12, after the bottom of the crucible furnace 14 contacts the bearing 1 on the top of the swing arm 3 of the anti-skid device 13, the swing arm 3 rotates under force, the crucible furnace 14 continues to move forward, and the swing arm 3 rotates. The arm 3 rotates to a horizontal state and remains horizontal until the crucible furnace 14 is pushed in place. At this time, the front end of the push-pull device of the transfer vehicle 15 is pressed against the crucible furnace 14 and the swing arm 3 is pressed against the bottom surface.

[0033] Step 2: After the crucible furnace 14 is in place, the push-pull device of the transfer vehicle 15 retreats and leaves the swing arm 3. After the swing arm 3 rotates from the horizontal to the vertical state under the gravity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com