Driving tool

A technology of driving tools and drivers, applied in the direction of nailing tools, manufacturing tools, nailing staple tools, etc., to achieve the effect of inhibiting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

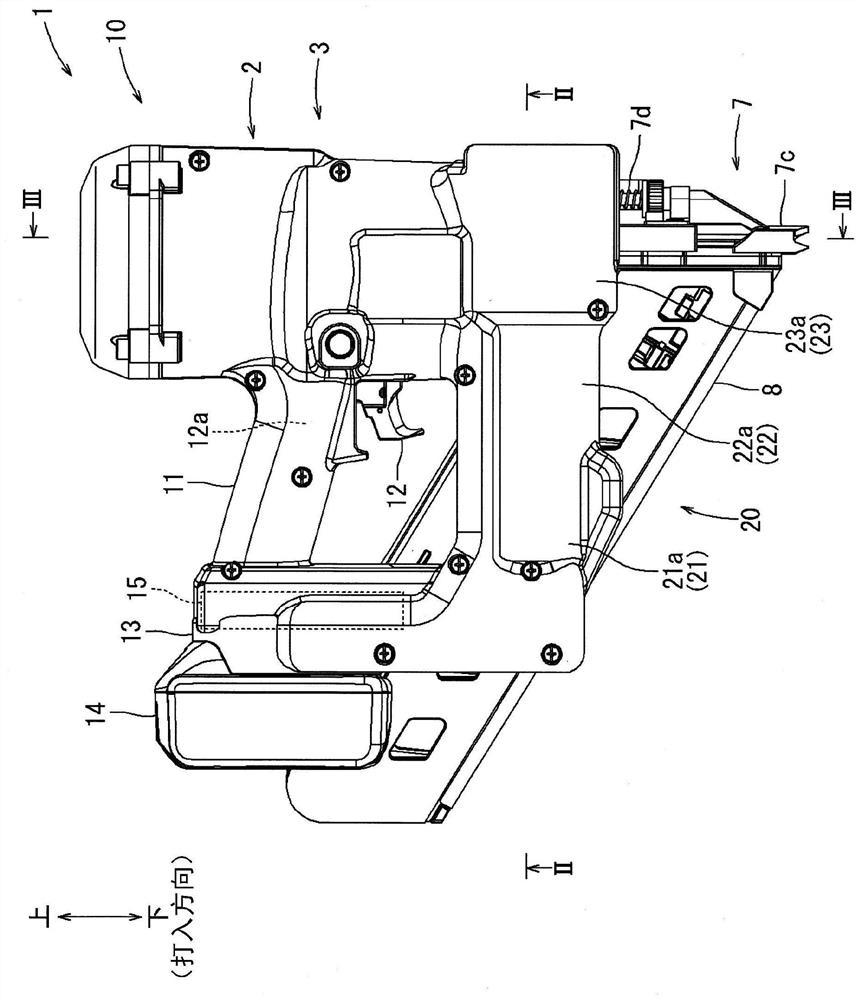

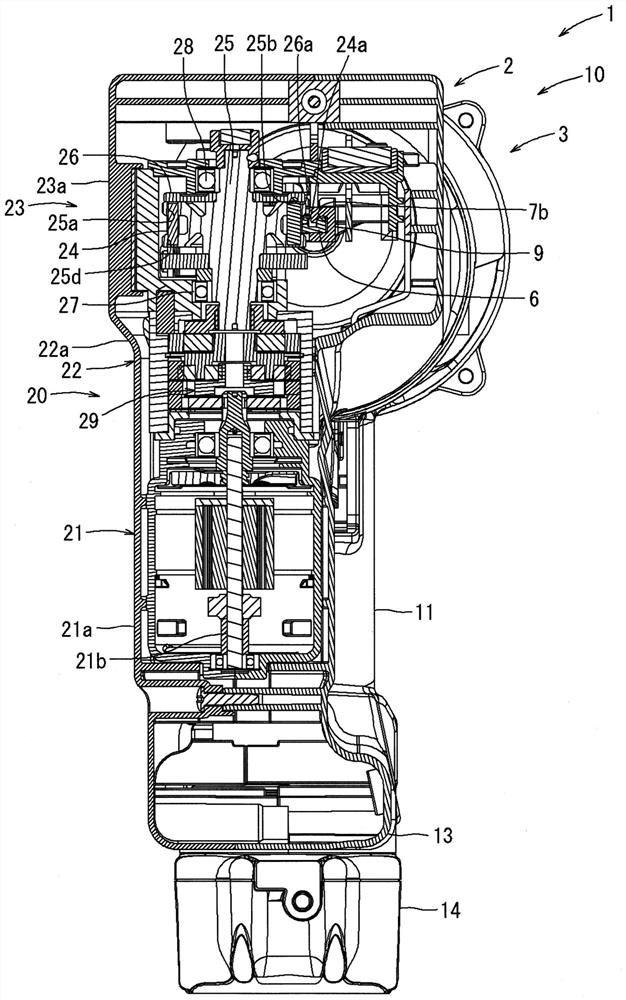

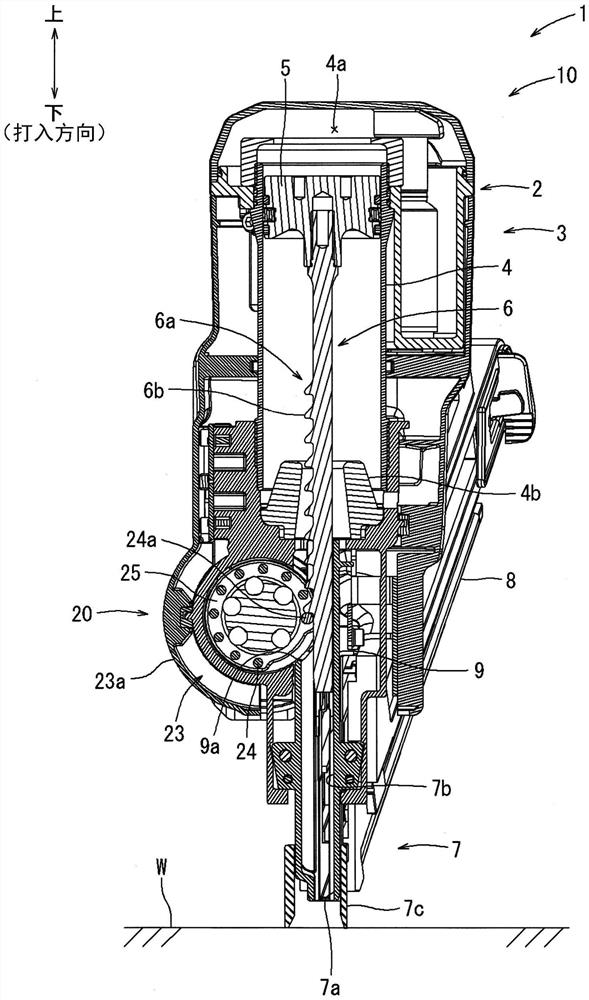

[0040] according to Figures 1 to 14 The driving tool 1 according to the first embodiment of the present invention will be described. In this embodiment, as a driving tool 1, a gas spring type driving tool is exemplified, which uses the air pressure of the gas (elastomer, fluid) enclosed in the pressure accumulating chamber 4a as a thrust for driving the driver n. like figure 1 As shown, the driving tool 1 has a tool body 10 having a substantially cylindrical body casing 2 and a handle portion 11 ; the handle portion 11 extends from the side of the tool body 10 . The top end of the tool body 10 is provided with a driving protrusion 7, and the driving protrusion 7 abuts against the material W to be driven to inject the driving piece n (see Figure 4 ). In the following description, the up-down direction is defined with the driving direction being down.

[0041] like image 3 As shown, the tool main body 10 has a driving mechanism 3 for driving the driving tool n downward. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com