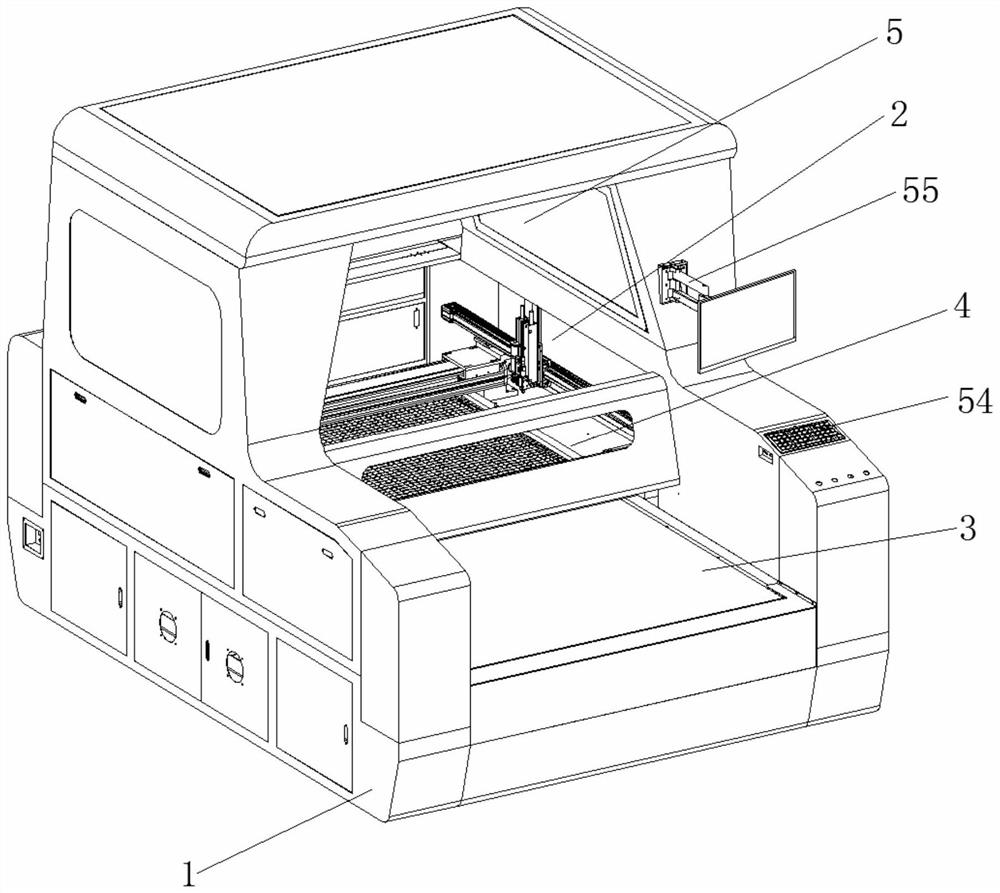

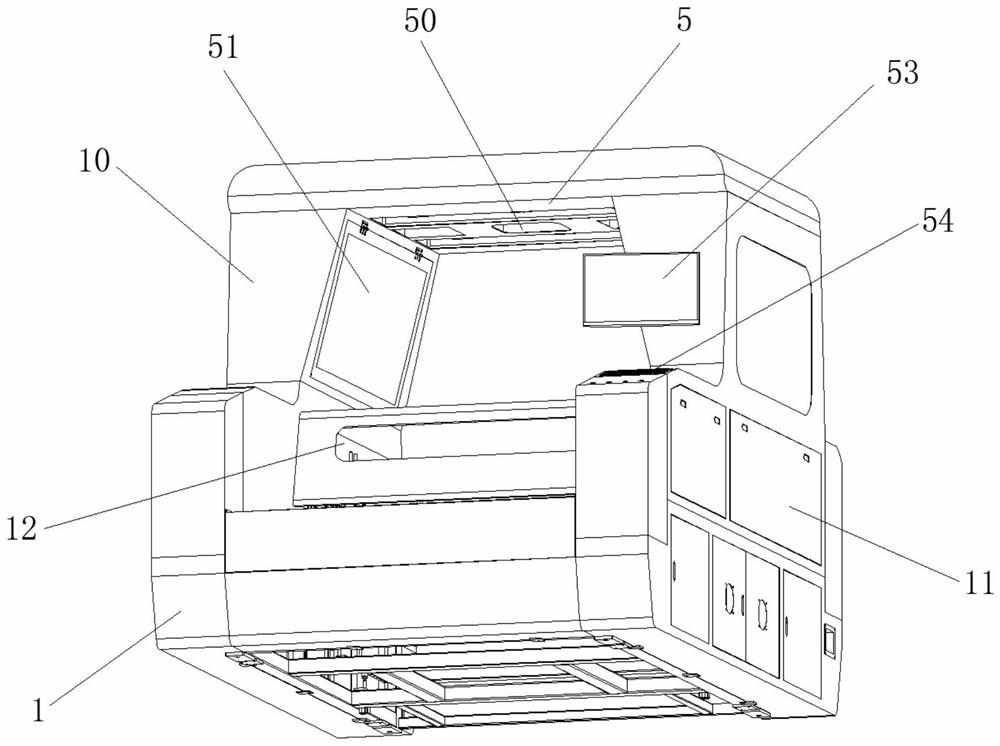

Double-shaft asynchronous line drawing machine

A line drawing machine, asynchronous technology, applied in shoe-making machinery, workshop equipment, manufacturing tools, etc., can solve the problems of high labor cost, power consumption, low labor efficiency, etc., to reduce production costs, improve efficiency, and save electricity. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

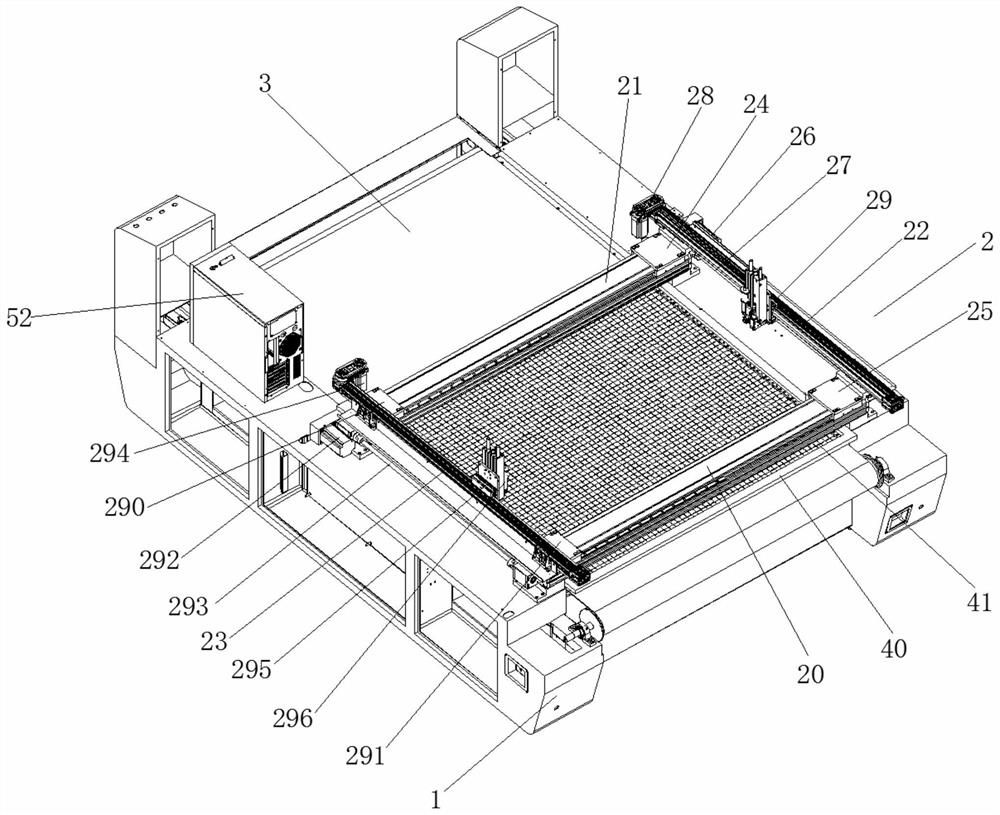

[0028] The first x-axis sliding rail 22 is controlled to complete the movement in the lateral direction by the second y-axis sliding block 25 on the first y-axis sliding rail 20 and the first y-axis sliding block 24 on the second y-axis sliding rail 21 , and The first x-axis slide rail 22 controls the first x-slider to complete the movement in the longitudinal direction, through the fourth y-axis slide 291 on the first y-axis slide rail 20 and the third y-axis slide on the second y-axis slide rail 21 The axis slider 290 controls the second x-axis slider 23 to complete the movement in the lateral direction, and the second x-axis slider 23 controls the second x-axis slider 295 to complete the movement in the longitudinal direction, so that the first x-axis slider 29. The inkjet assembly 296 on the second x-axis slider 295 can complete telemotion in the lateral and longitudinal directions, and the inkjet assembly 296 on the first x-axis slider 29 is driven by the first driving mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com