Drill bit positioning device of woodworking drilling equipment

A technology for drilling equipment and positioning devices, which is applied in the field of drilling machines, can solve the problems of poor equipment positioning and easy loosening of drill bits, and achieve the effects of reducing drilling errors, avoiding drill pipe deviation, and accelerating sliding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

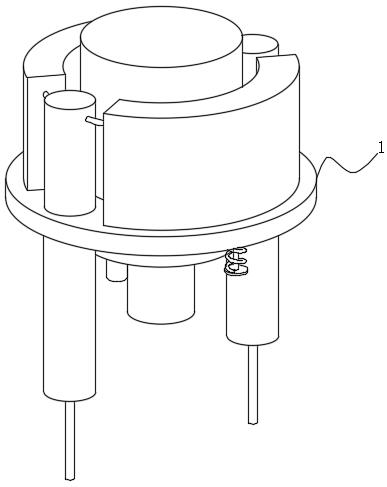

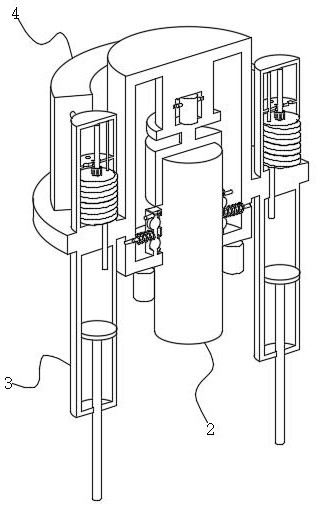

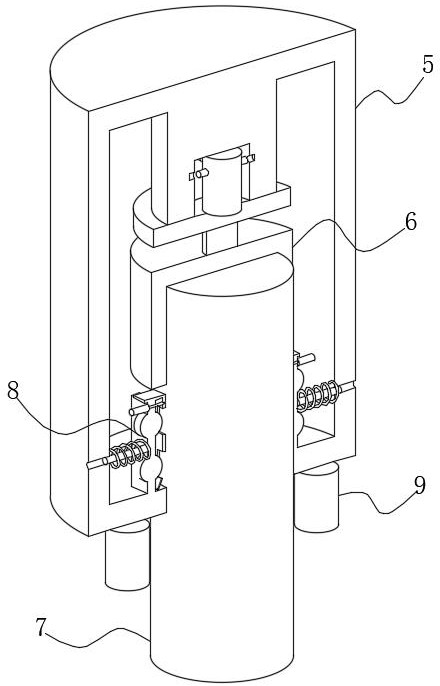

[0033] see Figure 1-Figure 8 , the present invention provides a technical solution: a drill bit positioning device for woodworking drilling equipment, comprising a connecting plate 1, the inner surface of the connecting plate 1 is fixedly connected with a driving device 2, and the left and right sides of the driving device 2 are provided with vertical buffers Device 3, the upper surface of the connecting plate 1 is fixedly connected with a pressure relief device 4, the driving device 2 includes a turning block 5, the inner surface of the turning block 5 is fixedly connected with a magnetic suction device 6, and the bottom of the magnetic suction device 6 is provided with a drill pipe 7 The outer surface of the drill pipe 7 is movably connected with a clamping device 8 , the bottom of the clamping device 8 is provided with a laser transmitter 9 , and the upper surface of the laser transmitter 9 is fixedly connected with the lower surface of the rotating block 5 .

[0034] The ...

Embodiment 2

[0040] see Figure 1-Figure 8 , the present invention provides a kind of technical scheme:

[0041] According to a drill bit positioning device of a woodworking drilling equipment according to claim 1, the vertical buffer device 3 comprises a pressing rod 25, the outer surface of the pressing rod 25 is slidably connected to the sealing pipe 26, and the top of the sealing pipe 26 is fixedly connected with a connecting pipe 27, A metering device 28 is fixedly connected to the top end of the connecting pipe 27 .

[0042] The metering device 28 includes a fixed cylinder 30, the inner surface of the fixed cylinder 30 is rotatably connected with a rotating shaft 31, the outer surface of the rotating shaft 31 is fixedly connected with a clamping block 32, the bottom of the clamping block 32 is provided with a screw 33, and the top of the screw 33 is provided with a movable plate 34, the inner surface of the movable plate 34 is slidably connected with a guide rod 35, the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com