Polyurethane tire production line

A polyurethane tire and production line technology, applied to tires, household appliances, other household appliances, etc., can solve the problems of low production efficiency and discontinuous movement of the injection head, so as to improve production efficiency, realize automatic movement, and cancel manual movement. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail by specific embodiments:

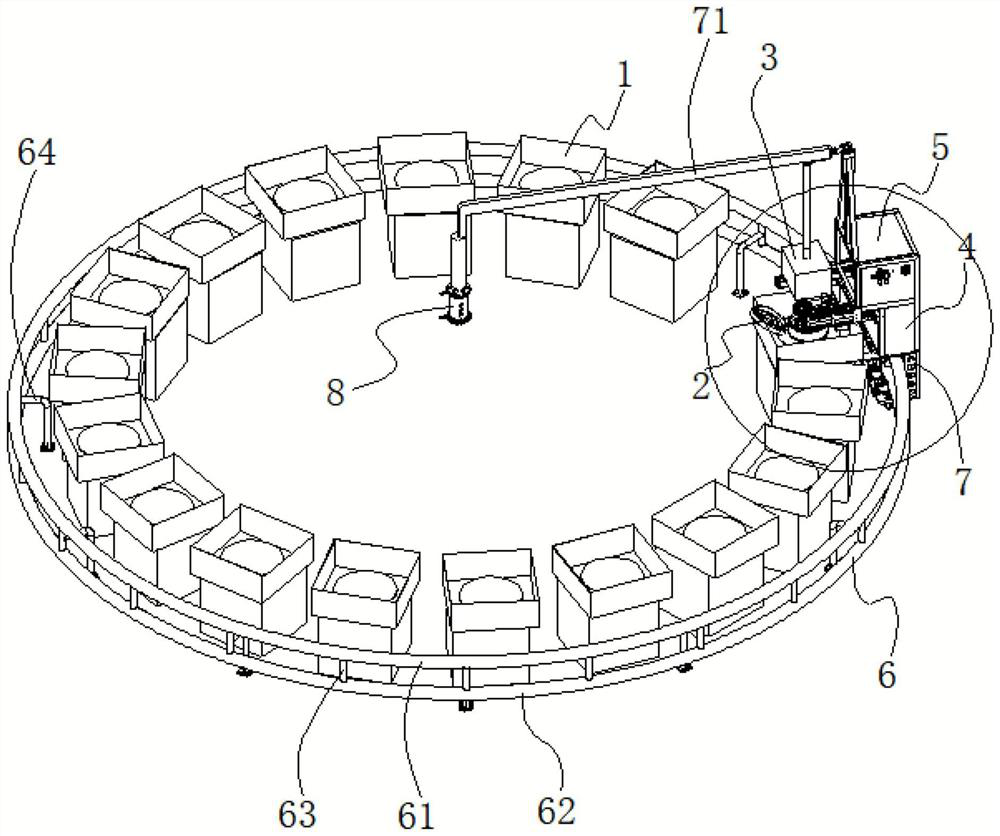

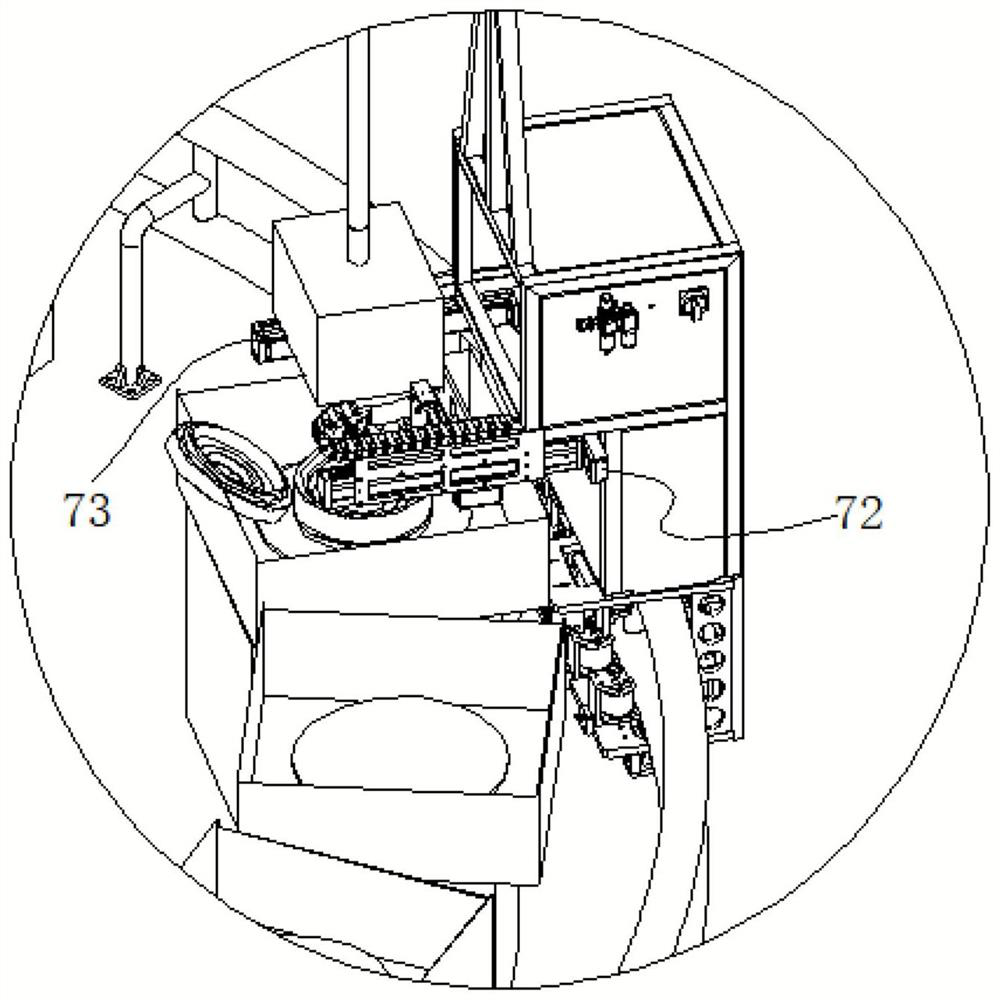

[0021] The example is basically as attached figure 1 As shown, the polyurethane tire production line includes a rotary turntable 1 on which a forming mold is placed, and a material injection head 3 for injecting material into the forming mold 2. The injection head 3 is fixed on the machine base 4 through a transmission device, so A cabinet 5 is fixed on the machine base 4, the feeding head 3 is connected with the material liquid storage tank through a feeding mechanism, the rotary turntable 1 is arranged in a circle, and the circularly arranged rotary turntable 1 The outer side is provided with a circular track 6, and the machine base 4 moves along the circular track 6 through the traveling device 7; A chute for clamping the circular track is formed between the clamping part and the inner clamping part, and a guide wheel is installed at the contact between the outer clamping part and the inner clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com