Movable sealant filling device and method for flexible vertical diaphragm wall

A mobile device and sealant technology, applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems of inconvenient automation of equipment, uneven filling, etc., and achieve the effect of improving terrain adaptability, improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

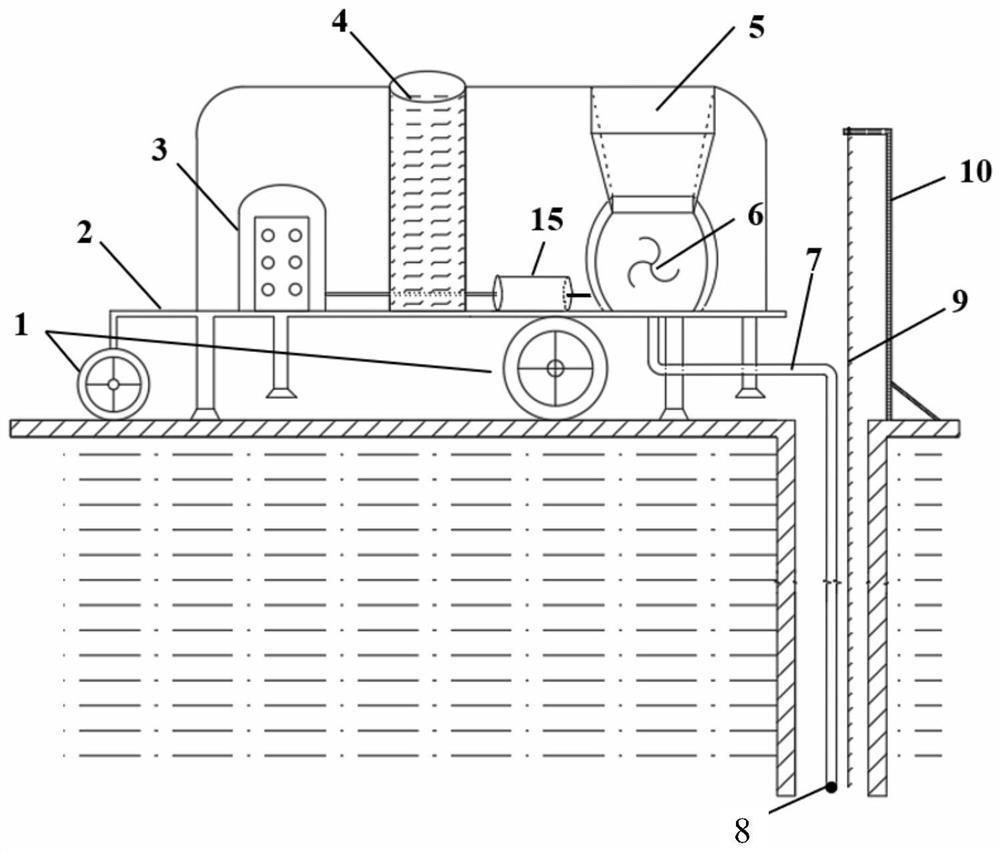

[0040] Such as figure 1 As shown, the present invention provides a movable sealant pouring device for a flexible vertical cutoff wall, comprising:

[0041] The carrying device 2 has several telescopic outriggers (such as jacks) or foldable outriggers, so that it can be stably supported on uneven ground, and can also be folded up for easy movement;

[0042] mobile means 1, such as wheels, enabling the carrying means 2 to walk on the ground;

[0043] The power unit 3, preferably an internal combustion engine, is fixed on the carrying device 2 and provides power to the moving device 1;

[0044] The water tank 4 is fixed on the carrying device 2 for containing the water liquid;

[0045] The material tank 5 is fixed on the carrying device 2 for containing the solid sealant;

[0046] The agitator 6 is fixed on the carrying device 2, and it is connected to the power device 3, and connected to the downstream of the water tank 4 and the material tank 5, and is used to carry out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com