Method for continuously synthesizing 3, 5-dimethylpyrazole

A technology of dimethylpyrazole and hydrazine hydrate, which is applied in organic chemistry and other fields, can solve problems such as safety risks, poor work efficiency, and unfavorable operation, and achieve accurate material ratio control, high product selectivity, and increased reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

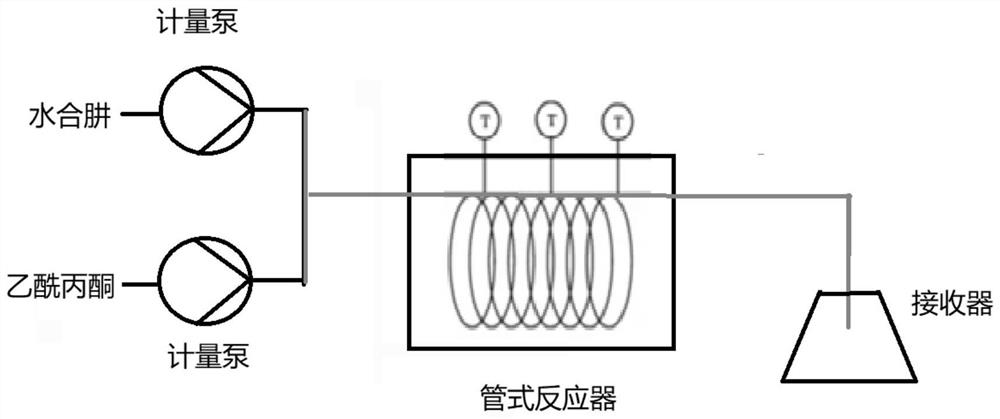

[0025] A method for continuous preparation of 3,5-dimethylpyrazole, comprising the following operation steps:

[0026] S1: Select a shell-and-tube reactor suitable for this experiment, equipped with a low-temperature circulating tank, the liquid holding capacity of the reactor is 30ml, and a sufficient amount of acetylacetone liquid is selected. The acetylacetone is a colorless liquid with a boiling point of 30 ml. 140℃, can also be used as an organic intermediate;

[0027] S2: Select a sufficient amount of hydrazine hydrate, which is a colorless liquid with a boiling point of 120°C; select a metering pump for backup, and the metering pump can be set to flow rate;

[0028] S3: drive acetylacetone into the tubular reactor through a metering pump, and the flow rate of acetylacetone is 50 mL / min;

[0029] S4: pass 40% hydrazine hydrate into the tubular reactor through a metering pump, and the flow rate of hydrazine hydrate is 250 mL / min;

[0030] S5: In the steps of S3 and S4, ...

Embodiment 2

[0034] A method for continuous preparation of 3,5-dimethylpyrazole, comprising the following operation steps:

[0035] S1: Select a shell-and-tube reactor suitable for this experiment, equipped with a low-temperature circulating tank, the liquid holding capacity of the reactor is 30mL, and a metering pump is selected for standby. The metering pump can be set to flow rate;

[0036] S2: Weigh enough hydrazine hydrate and acetylacetone liquid;

[0037] S3: drive acetylacetone into the tubular reactor through a metering pump, and the flow rate of acetylacetone is 20mL / min;

[0038] S4: pass 45% hydrazine hydrate into the tubular reactor with a metering pump, and the flow rate of hydrazine hydrate is 100 mL / min;

[0039] S5: acetylacetone and hydrazine hydrate are simultaneously reacted in a tubular reactor;

[0040] S6: The molar ratio of acetylacetone to hydrazine hydrate is 1:1.10. After the internal reaction of the tubular reactor is completed, high-purity 3,5-dimethylpyrazol...

Embodiment 3

[0043] A method for continuous preparation of 3,5-dimethylpyrazole, comprising the following operation steps:

[0044] S1: Select a shell-and-tube reactor suitable for this experiment, equipped with a low-temperature circulation tank, the liquid holding capacity of the reactor is 30mL, and a sufficient amount of acetylacetone liquid is weighed;

[0045] S2: Weigh a sufficient amount of hydrazine hydrate; select a metering pump for backup, and the metering pump can set the flow rate;

[0046] S3: drive acetylacetone into the tubular reactor through a metering pump, and the flow rate of acetylacetone is 15mL / min;

[0047] S4: pass the 50% hydrazine hydrate metering pump into the tubular reactor, and the hydrazine hydrate flow rate is 75 mL / min;

[0048] S5: In the steps of S3 and S4, acetylacetone and hydrazine hydrate are simultaneously reacted in the tubular reactor;

[0049] S6: The molar ratio of acetylacetone to hydrazine hydrate is 1:1.15. After the reaction in the tubul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com