Discharging mechanism of automatic mechanical equipment

A technology of mechanical equipment and rotating mechanism, which is applied in the direction of feed, mixers, mixer accessories, etc., can solve the problems of inconvenient mixing ratio and low mixing efficiency of feed mixers, achieve good mixing effect, improve mixing efficiency, and improve mixing ratio Control the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

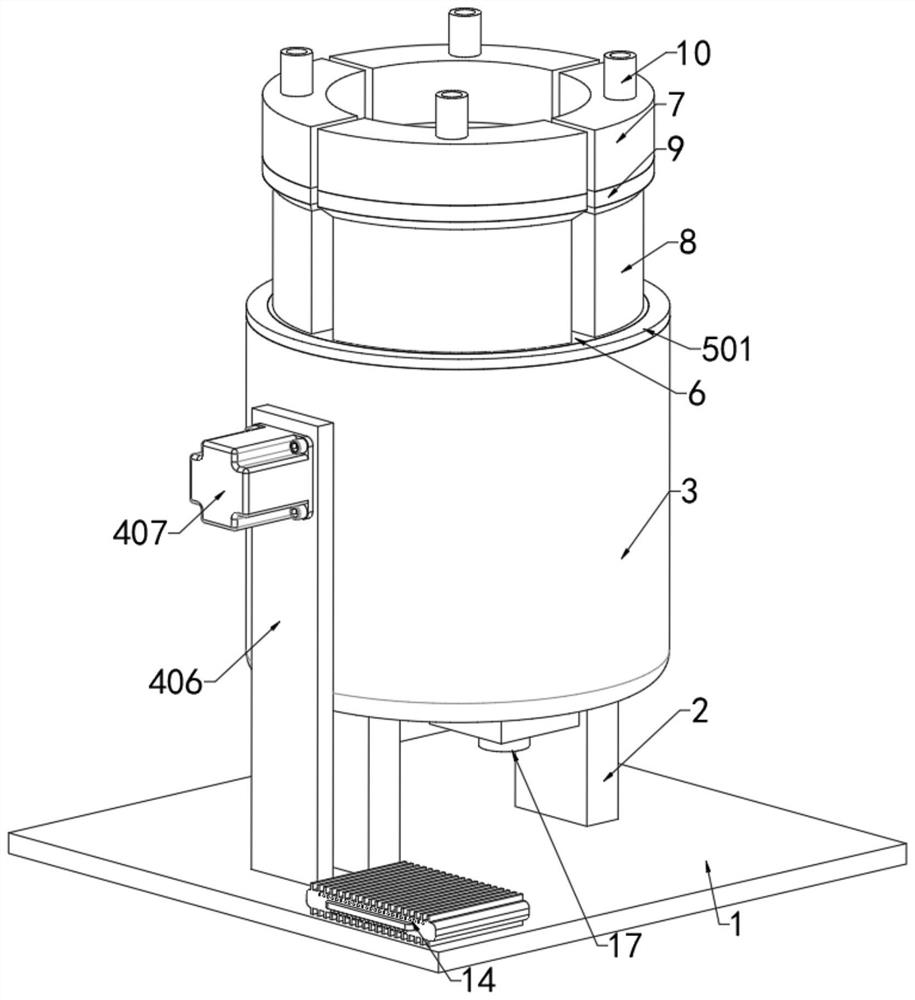

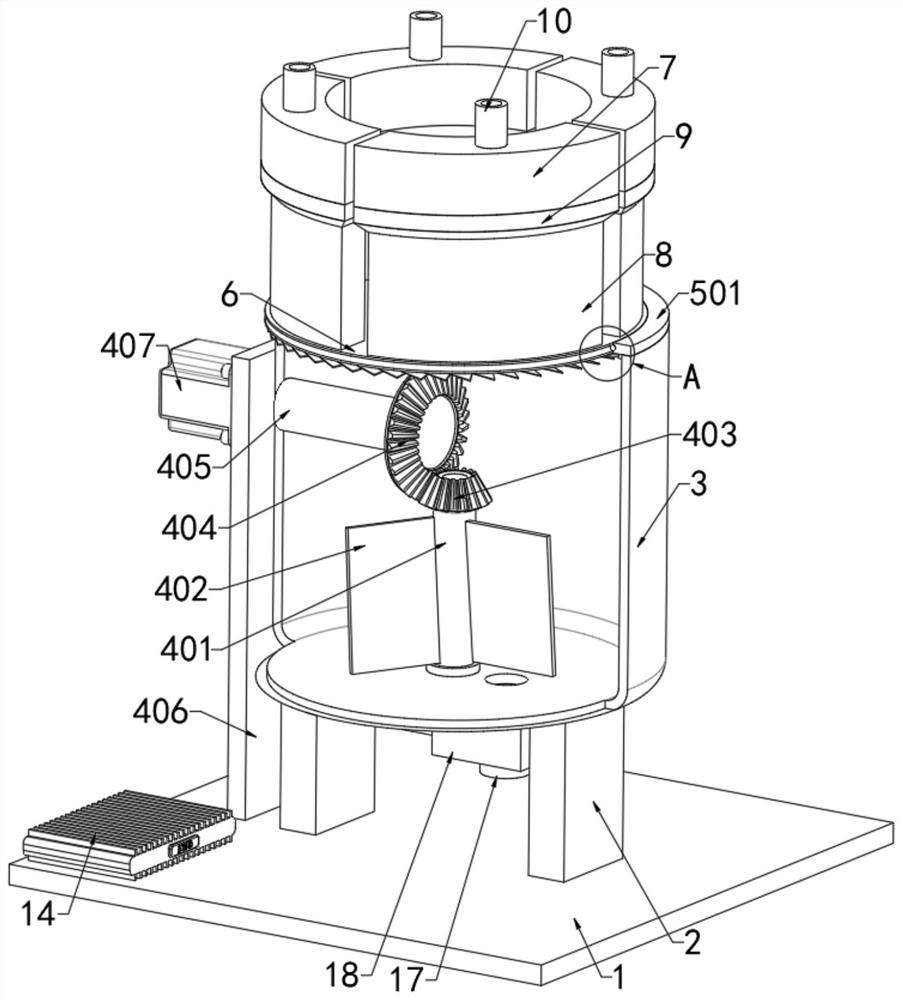

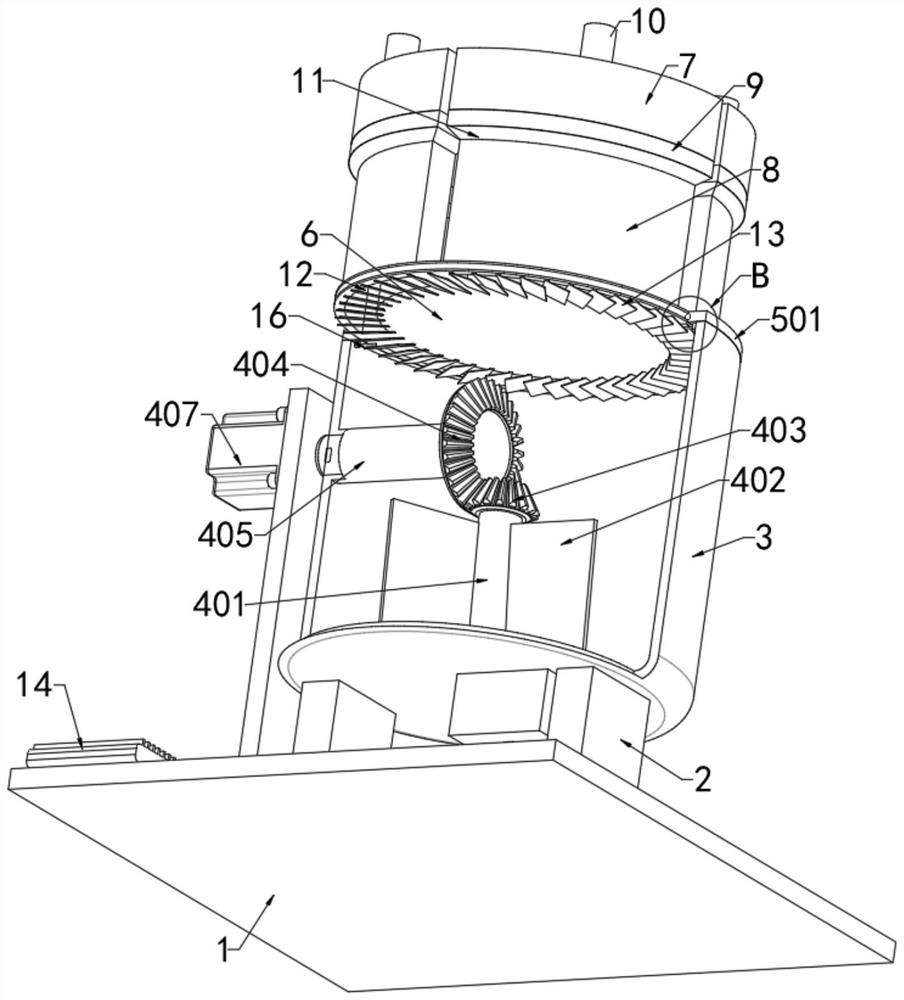

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as they are intended to limit the scope of the invention.

[0032] During the feeding of poultry and livestock, the preparation of feed is very important. The feed contained in the feed is a variety of feeds, which requires mixing and stirring a plurality of feeds using a mixer. At present, the mixer of stirring feed is divided into vertical and horizontal.

[0033] The inventors have been in-depth investigation and research on the feed mixing process: the mixer requires the user to add a variety of feed in a mixing bar before stirring, but the ratio is not convenient for control and adjustment during the actual operation. There is an error such that the mixing stir effect is poor, and such a discharge method such that the feed stack is placed together, so that the agitation efficiency is low.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com