Breathable stretchable conductive yarn and preparation method and application thereof

A conductive yarn and yarn technology, which is applied in yarn, filament/thread forming, textile and papermaking, etc., can solve the problems that have not yet been involved in stretchable one-dimensional elastic conductive fiber, and achieve rich structure levels and low cost , Improving the effect of physiological comfort and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A breathable and stretchable conductive yarn:

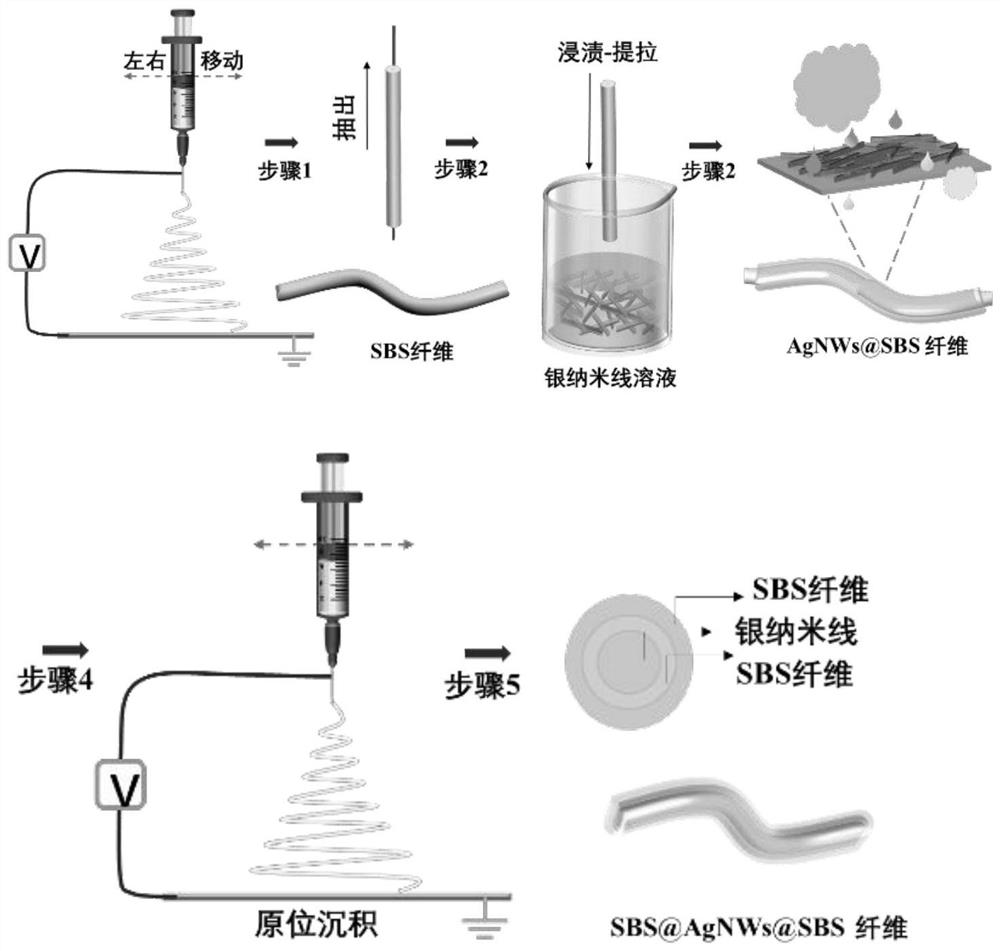

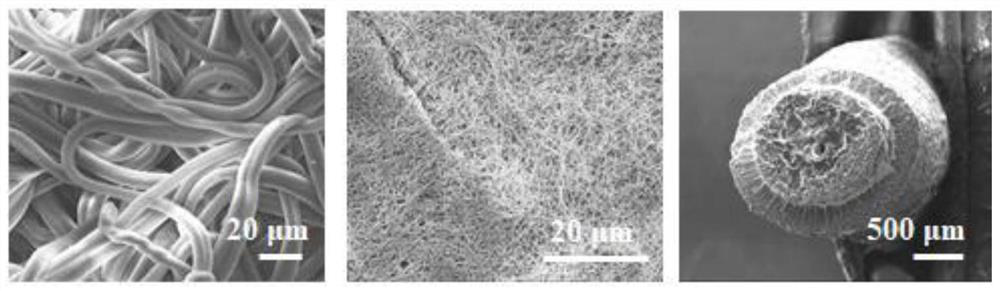

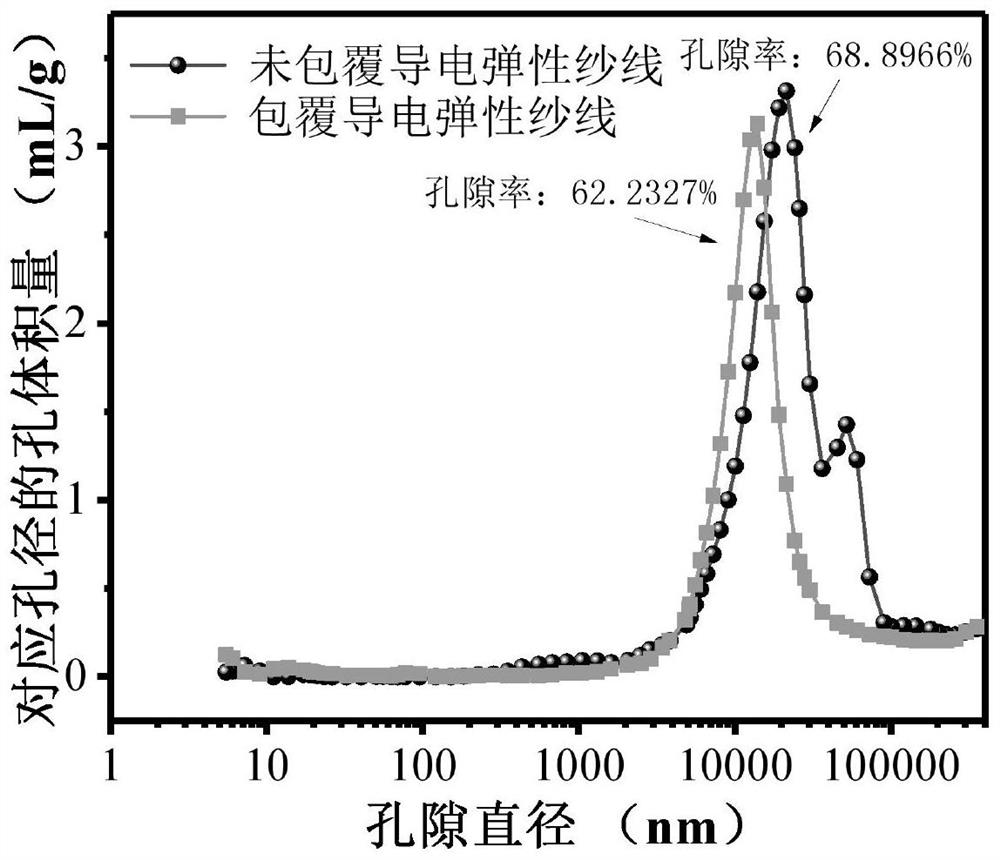

[0052] It includes a porous elastic base layer, a conductive layer and a porous outer covering layer in sequence from the inside to the outside.

[0053] The porous elastic base layer and the porous outer covering layer are electrospun micro-nano SBS fibers, and the conductive layer is silver nanowires.

[0054] A preparation method of breathable and stretchable conductive yarn, combining figure 1 shown, including the following steps:

[0055] (1) Preparation of spinning solution: take SBS raw material and add it to dichloroethane, and place it in a constant temperature heating stirrer to stir (typical stirring speed is 500rpm, stirring time is 2 hours), and set lower than dichloroethane The heating temperature at the boiling point (typical heating temperature is 60° C.), to accelerate the dissolution of SBS, and finally obtain a SBS spinning solution with a concentration of 25wt%;

[0056] (2) Preparation of SBS yarn: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap