Unit assembly type aluminum plate suspended ceiling structure and mounting method

An installation method and prefabricated technology, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of low economic benefits, long resource occupation period, large space occupation, etc., to reduce construction operation risks and reduce high-altitude operations. The effect of saving time and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

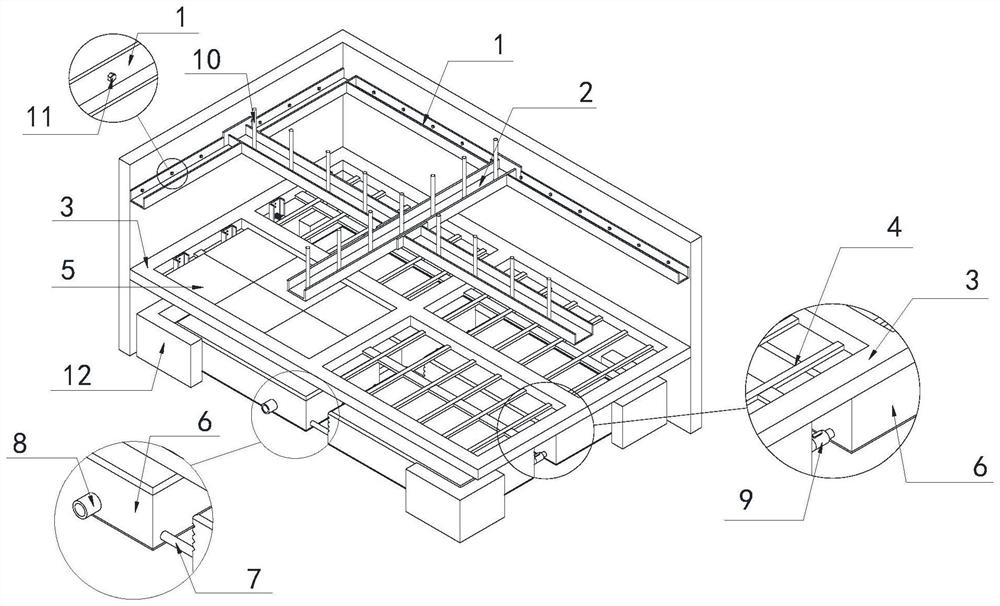

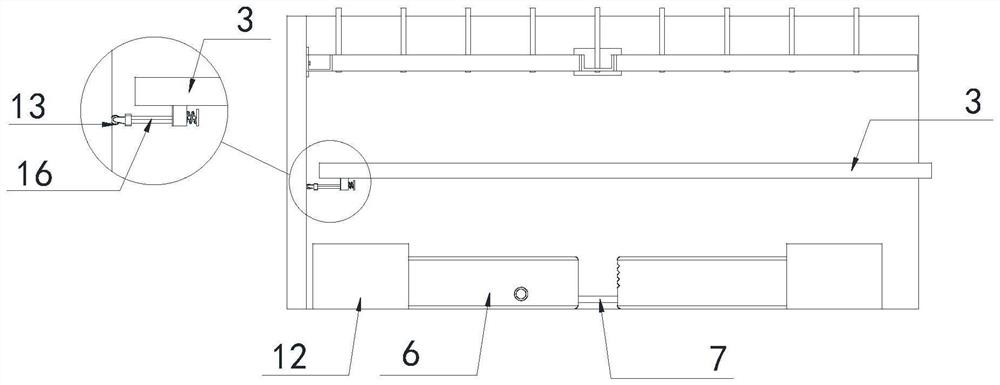

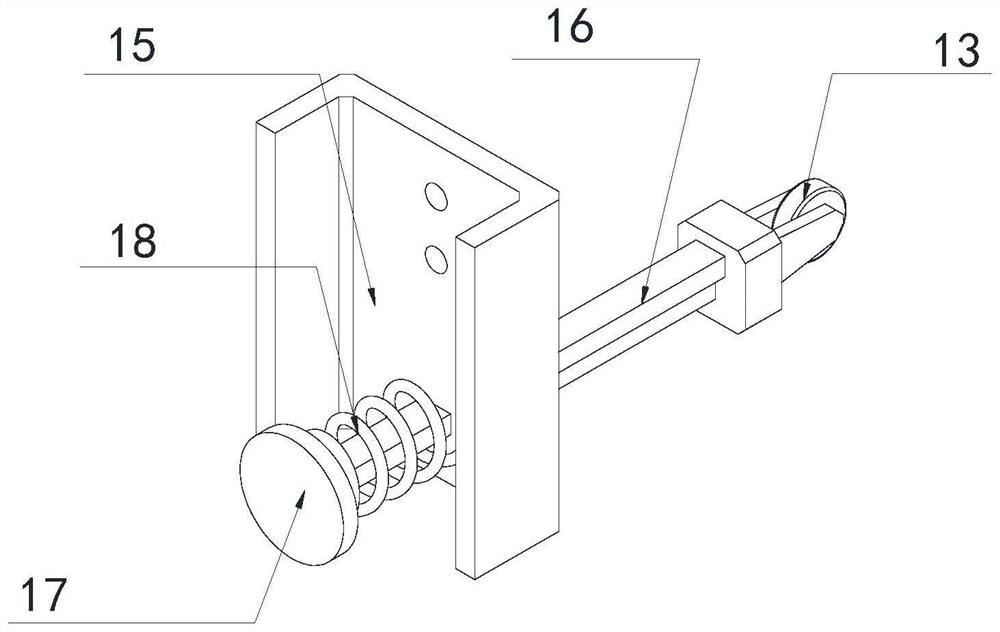

[0035] The embodiment of the present invention provides a unit-assembled aluminum plate ceiling structure, which is used to simplify the assembly of the ceiling structure, does not need to rent too much scaffolding, and can be erected and fixed as a whole after completing the installation operation on the ground, which can reduce the risk of high-altitude operations. It can also effectively improve work efficiency and reduce construction costs. In order to achieve the above technical effects, the setting of the ceiling structure here includes the first keel installed on the elevated space, and the setting of the first keel includes the side main keel 1 installed on the wall surface and the side The middle main keel 2 on the inner side of the main keel 1, the middle main keel 2 is used to build the foundation support to provide force for the ceiling structure, and can be installed on the side main keel 1;

[0036] In order to realize the laying of the ceiling structure on the gr...

Embodiment 2

[0045] An embodiment of the present invention provides a method for installing a unit-assembled aluminum plate ceiling, including any one of the assembled aluminum plate ceiling structures in the embodiment, and the installation of the ceiling plate 5 can be easily realized through the relevant structure in the first embodiment. The method includes: Follow the steps below:

[0046] Build the first keel, and design, arrange and install the opposite side main keel 1 and middle main keel 2 according to the scale of the scene;

[0047] Preset air cushions 6 on the ground according to the distribution position of the first keel, and connect each air cushion 6;

[0048] A second keel 3 is built below the first keel, a mesh frame 4 is built after the main support structure of the second keel 3 is built, and a ceiling board 5 is laid after the mesh frame 4 is built;

[0049] Adjust the second keel 3 to a suitable position and then inflate the air cushion 6 (the air cushion 6 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com