Quickly-mounted steel column mounting structure and mounting process thereof

A technology for installing structures and steel columns, applied in the directions of columns, pillars, piers, etc., can solve problems such as troublesome connection and operation of steel columns, reduce the possibility of mutual separation, facilitate operation, and improve shear resistance and bending resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

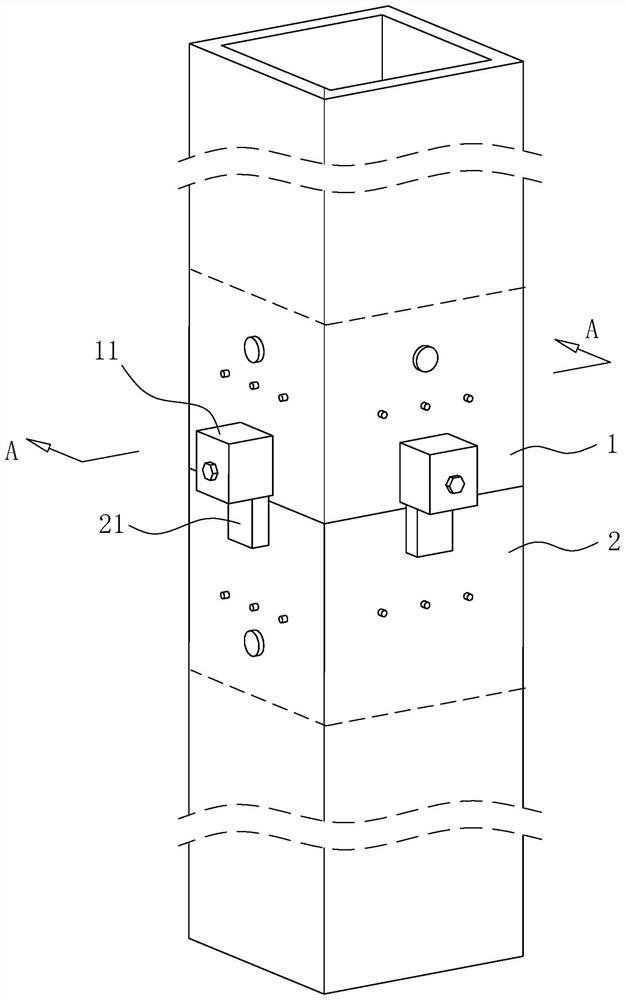

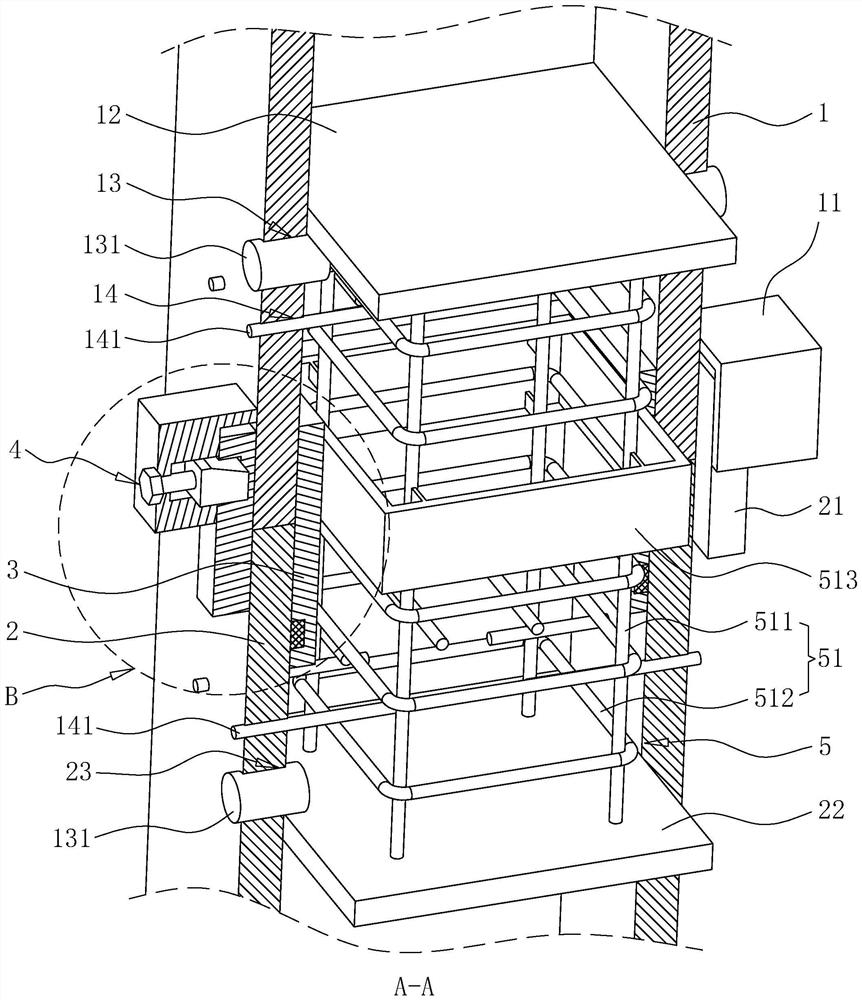

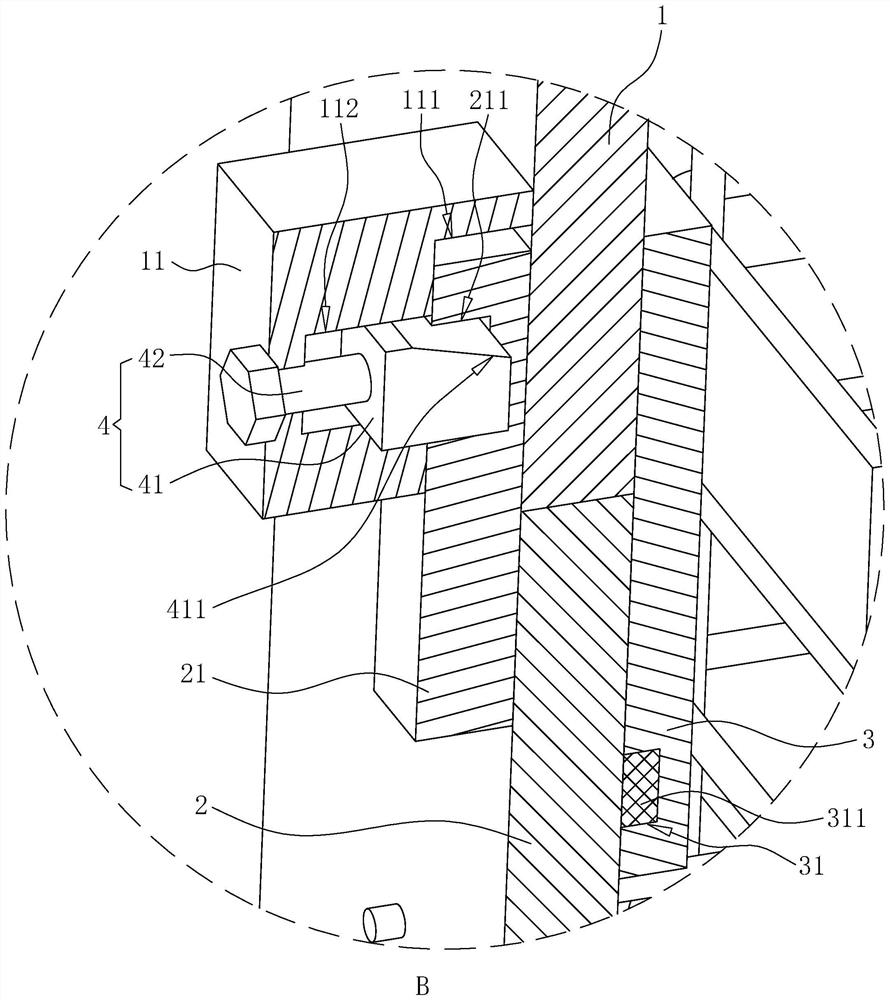

[0040] Attached to the following Figure 1-4 This application will be described in further detail.

[0041] The embodiment of the present application discloses a quick-installation steel column installation structure. refer to figure 1, a quick-installed steel column installation structure includes an upper connecting steel pipe 1 and a lower connecting steel pipe 2; the upper connecting steel pipe 1 is used to be fixedly installed at one end of the steel column, and the lower connecting steel pipe 2 is used to be fixedly installed at one end of another steel column . The upper connecting steel pipe 1 and the lower connecting steel pipe 2 can be integrally formed with the steel column or fixedly connected by welding, riveting and bolting; in this embodiment, the upper connecting steel pipe 1 and the lower connecting steel pipe 2 are respectively connected with the corresponding steel column. One piece.

[0042] refer to figure 1 and figure 2 , When the two steel columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com