Construction method for safe crossing of fractured stratum TBM (tunnel boring machine)

A construction method and stratum technology, which can be used in the installation of bolts, earth drilling, underground chambers, etc., can solve the problems of TBM being stuck and trapped, and achieve the effects of reducing the risk of getting stuck, increasing the strength of the initial support, and improving the stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Attached to the following figure 1 The preferred embodiments of the present invention are described, and it should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

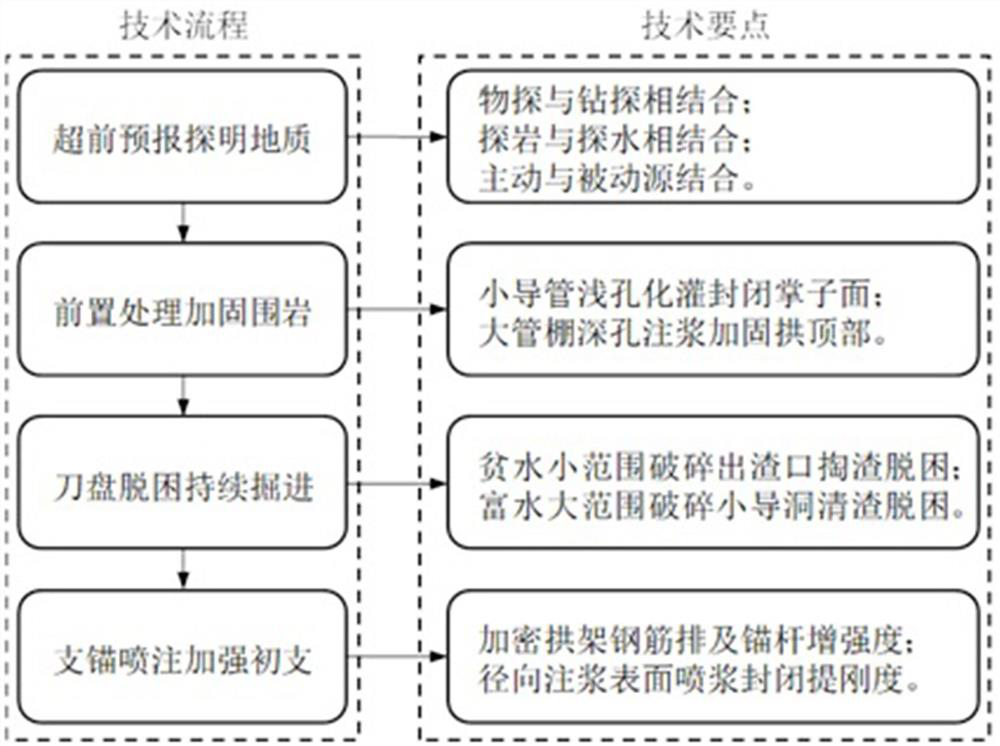

[0022] A construction method for safely crossing a broken stratum TBM of the present invention comprises the following specific steps:

[0023] Step 1: advance prediction of tunnel geology; wherein, the method for advance prediction of tunnel geology is: using the seismic wave advance geophysical method to detect the location of the unfavorable rock mass in the tunnel, using the electromagnetic wave advance geophysical method to detect the location of the tunnel unfavorable water body, and then Use drilling method to confirm the poor degree of tunnel geology;

[0024] Step 2: Pre-treatment and reinforcement of the surrounding rock; wherein, the method of pre-treatment and reinforcement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com