Construction method of subway tunnel passing through building in fractured rock formation

A construction method and building technology, applied in tunnels, earthwork drilling, mining equipment, etc., to achieve the effects of reducing sensitivity, improving the bearing capacity of surrounding rock, and avoiding earthquake damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described with reference to the accompanying drawings.

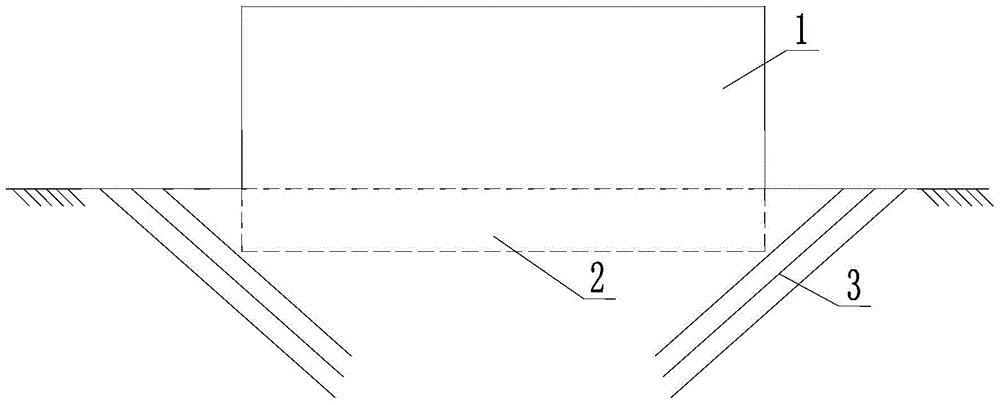

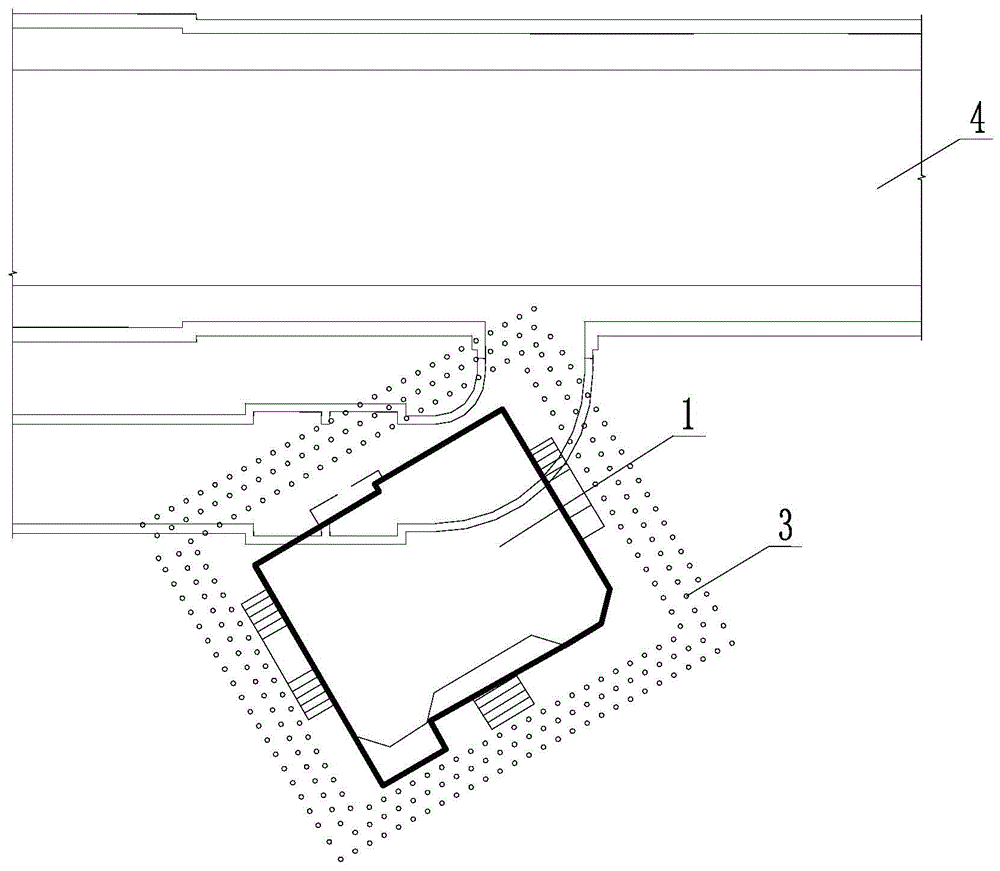

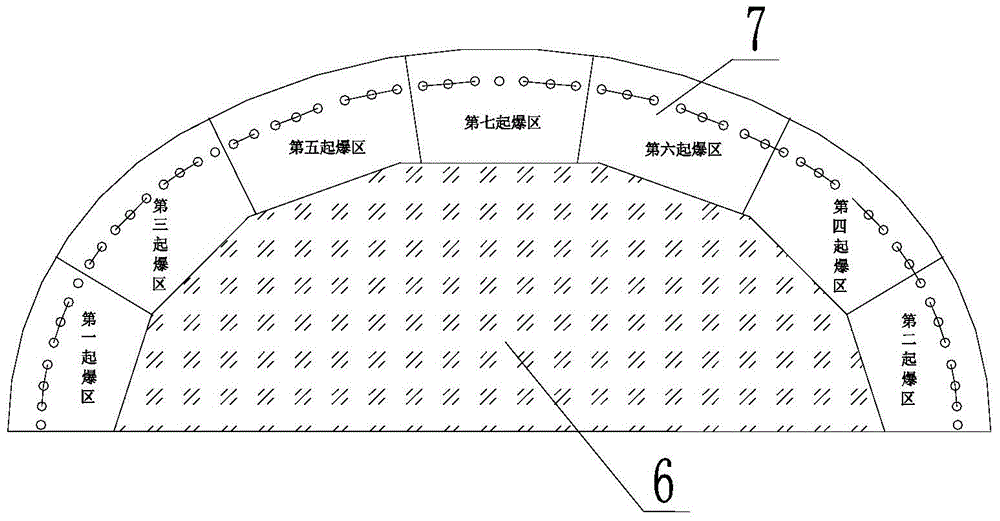

[0030] The subway station tunnel 4 described in this embodiment has an excavation width of 21.9m, a total height of 16.2m, and an upper soil thickness of 9-12m. The surrounding rock is mainly full and strongly weathered granite, with broken rock formations and well-developed joints. The grade of the surrounding rock is Level V. The tunnel 5 attached to the station is excavated with a width of 9m and a height of 7.1m. It passes through the national key building 1 with a crossing length of 18.2m. The vertical height to the building base 2 is only 8.5m. It is a strip-shaped rubble. In order to control the uneven settlement of the building 1 caused by tunnel construction in the fractured rock stratum and avoid damage to the building 1 caused by blasting vibration, the technical solution of the present invention is proposed.

[0031] The present embodiment method comprises the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com