Double-valve control system and method applied to supercritical carbon dioxide turbine

A technology of carbon dioxide and valve control, which is applied in the direction of safety devices, combustion engines, machines/engines, etc., can solve the problems of large axial force of the rotor, damage to the unit, and long warm-up time, etc., to maintain axial force, Reduce the warm-up time and reduce the effect on the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

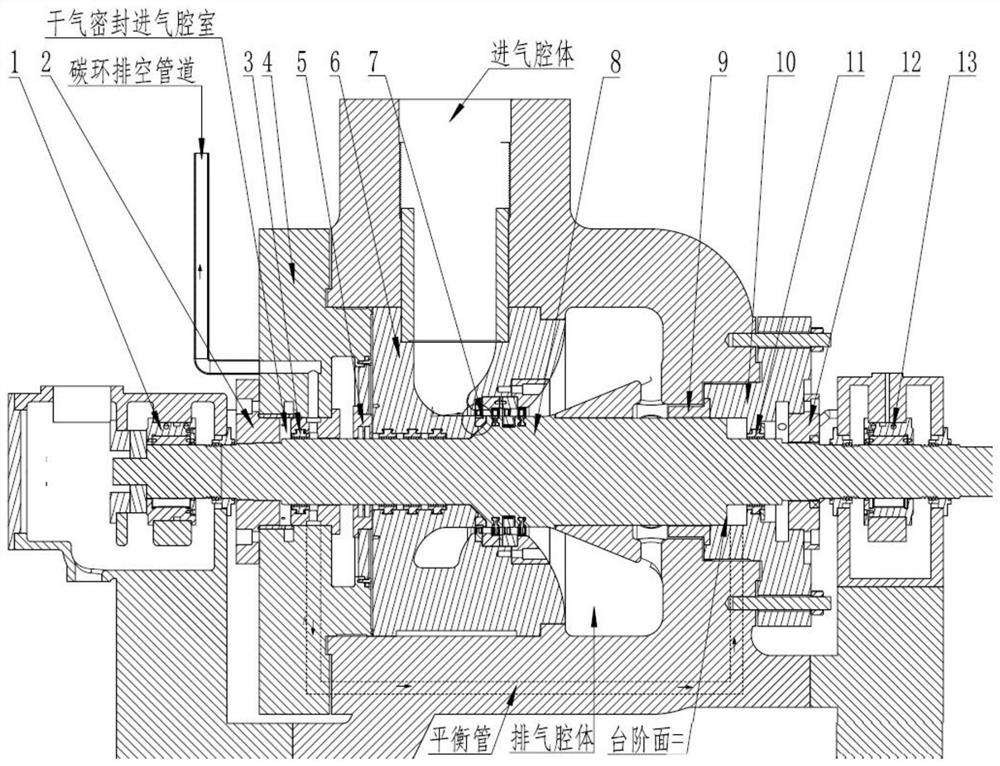

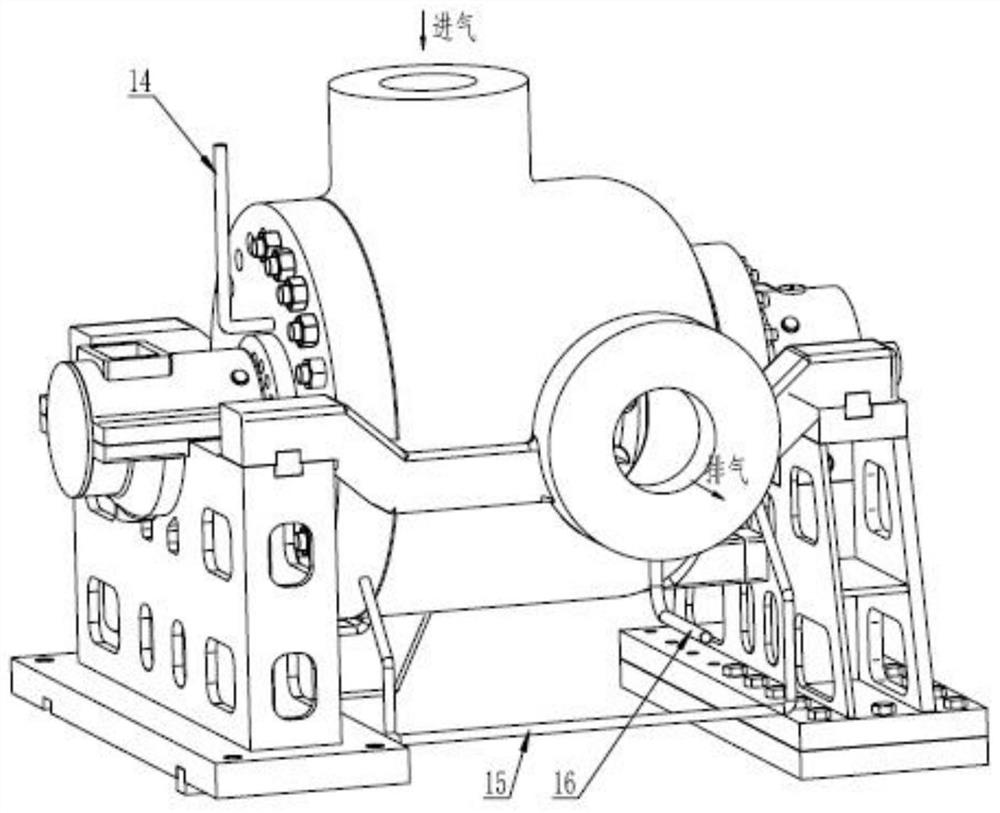

[0022] An embodiment of a dual-valve control system applied to a supercritical carbon dioxide turbine:

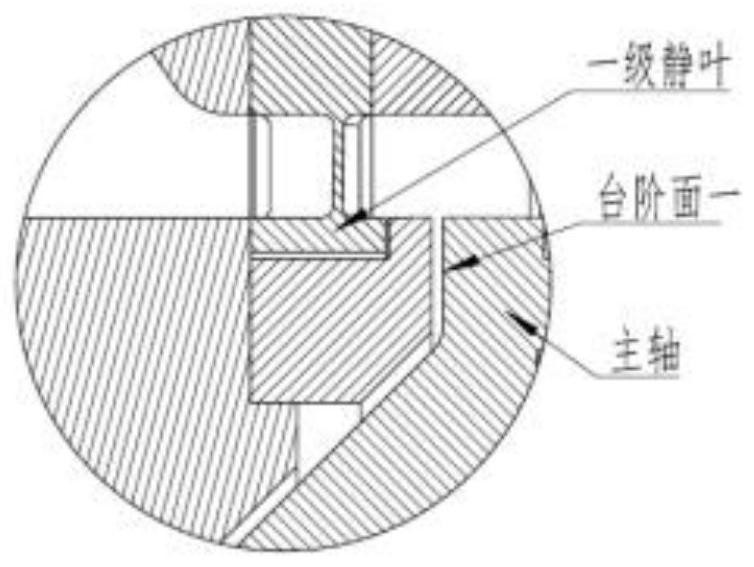

[0023] see figure 1 , It is mainly composed of thrust and radial bearings, dry gas seals, sparse tooth seals, carbon ring seals, main shaft, inner cylinder block, outer cylinder block, moving and stationary blades, main shaft, end cover, etc. Among them, the thrust bearing mainly bears the axial direction of the main shaft. Thrust and dry gas seal are the main sealing components of the turbine. A temperature sensor is installed on the surface of the dry gas seal shell, and a regulating valve and a temperature sensor are installed on the intake pipe of the dry gas seal. During normal operation, the dry gas seal leads to high-pressure sealing gas. , to prevent the leakage of the medium inside the turbine; the airflow inside the turbine drives the main shaft to rotate through the work of the moving and stationary blades, and there are pressure sensors before and after the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com