Constant-variable multi-way valve and hydraulic system thereof

A multi-way valve and variable technology, which is applied in the direction of fluid pressure actuators, servo motor components, combustion engines, etc., can solve the problem that variable variable pumps cannot play the role of adjusting energy saving effects, and achieve improved action coordination, energy saving, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

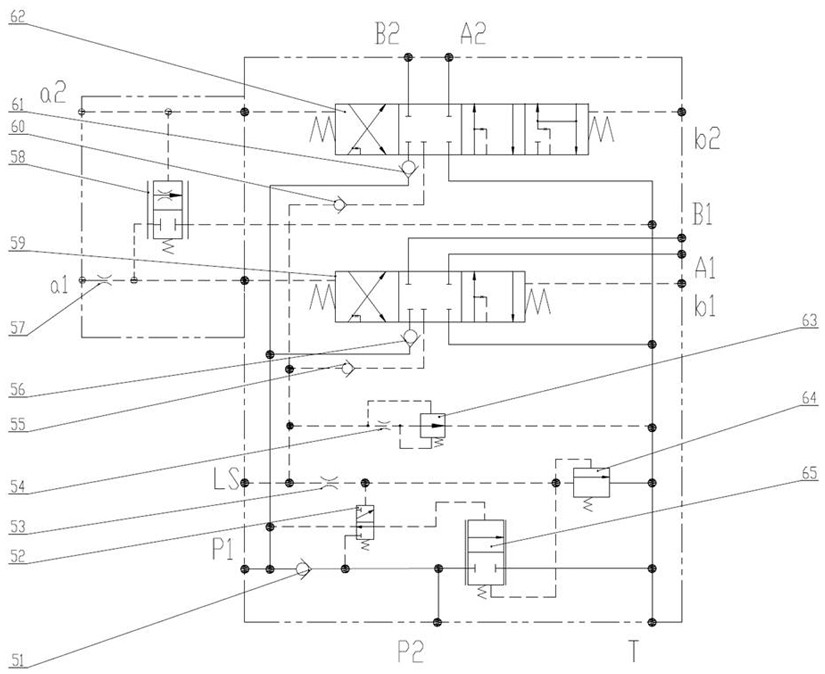

[0041] This embodiment discloses a constant variable multi-way valve 5, combined with figure 1 As shown, it includes a pilot-controlled first main spool 59 with a three-position and closed-center position, a pilot-controlled second main spool 62 with a four-position and closed-center position, and ports P1, P2, LS, and T. , a1 port, a2 port, b1 port, b2 port, A1 port, A2 port, B1 port, B2 port.

[0042] The P1 port is used to connect the variable pump 2, and the P2 port is used to connect the quantitative pump 3.

[0043] The LS port is used to connect with the load feedback port of the variable pump 2 to feed back the load pressure to the variable pump 2, so that the variable pump 2 provides pressure oil according to the feedback pressure signal.

[0044] Port T is connected to hydraulic oil tank 1 for oil return of the hydraulic system.

[0045] The P2 port joins with the P1 port through the confluence check valve 51. The P1 port is connected to the oil inlet oil circuit o...

Embodiment 2

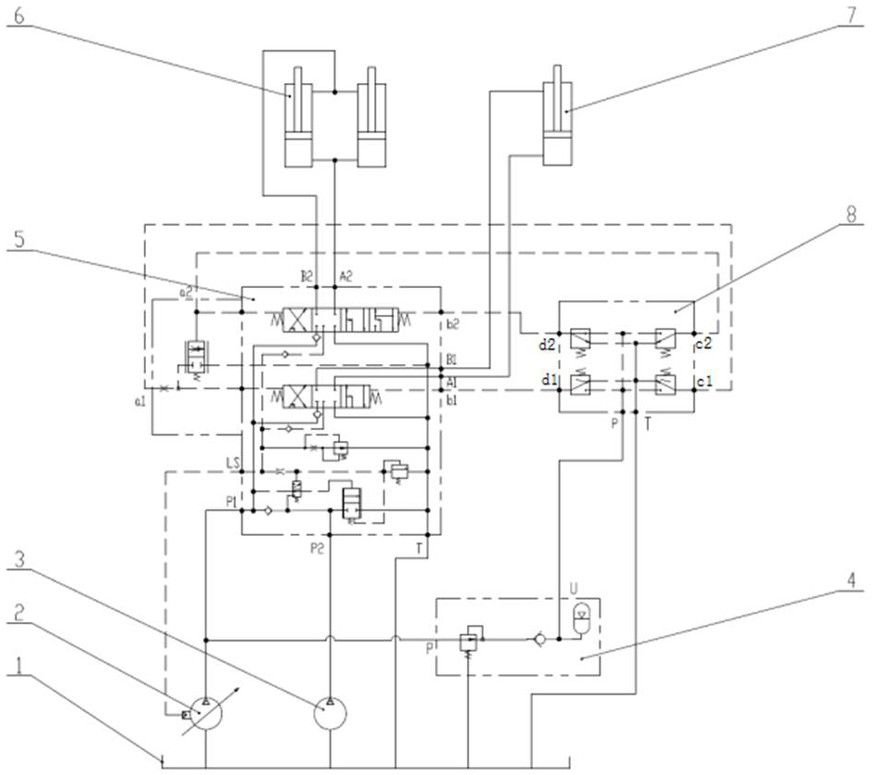

[0055] This embodiment discloses a constant variable hydraulic system of a loader, such as figure 2 As shown, the variable pump 2 draws hydraulic oil from the hydraulic oil tank 1 to supply the P1 port of the fixed variable multi-way valve 5, and the quantitative pump 3 draws hydraulic oil from the hydraulic oil tank 1 to supply the P2 port of the fixed variable multi-way valve 5. The two working oil ports A1 and B1 of the first main spool 59 are respectively connected to the rodless cavity and the rod cavity of the first actuator 6 , and the two working oil ports A2 and B2 of the second main spool 62 The ports are respectively connected with the rodless cavity and the rod cavity of the second actuator 7, and the pilot control oil ports a1, b1, a2 and b2 of the first main spool 59 and the second main spool 62 are respectively connected with the pilot The c1 port, c2 port, d1 port, and d2 port of the valve 8 are connected, the P2 port is connected with the pump port of the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com