Heat preservation construction method for preheating zone of double-chamber kiln

A construction method and technology of preheating zone, applied in the field of kilns, can solve problems such as unfavorable maintenance spraying construction, spray coating falling off, etc., and achieve the effects of good protection, reduction of consumables, and avoidance of high temperature erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail:

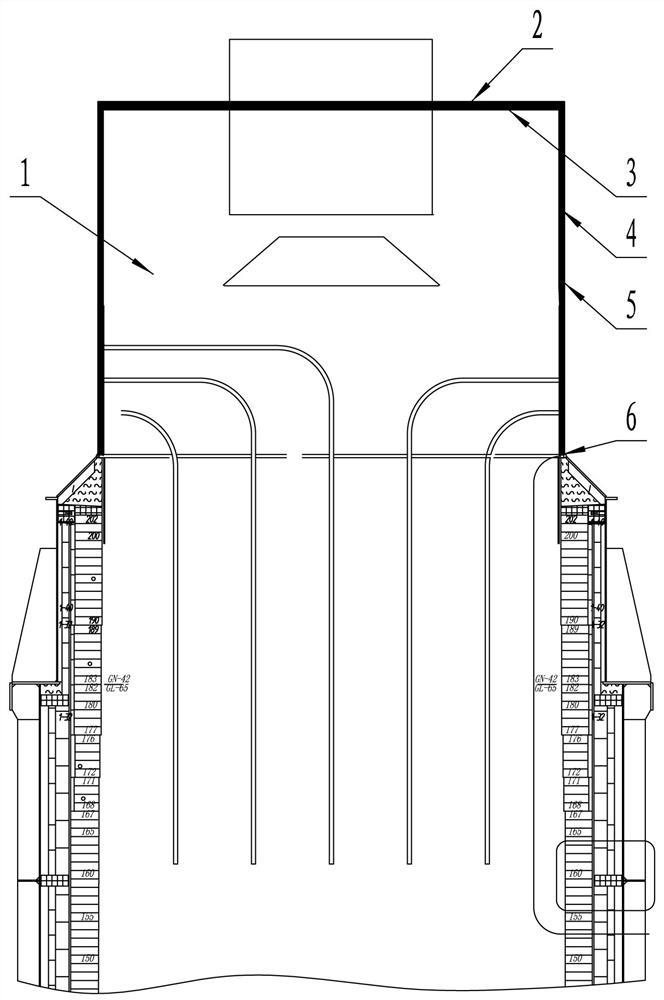

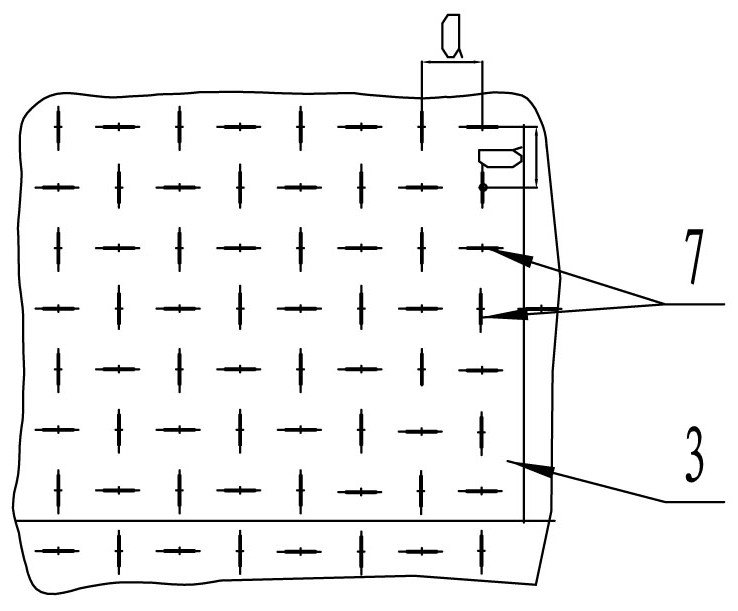

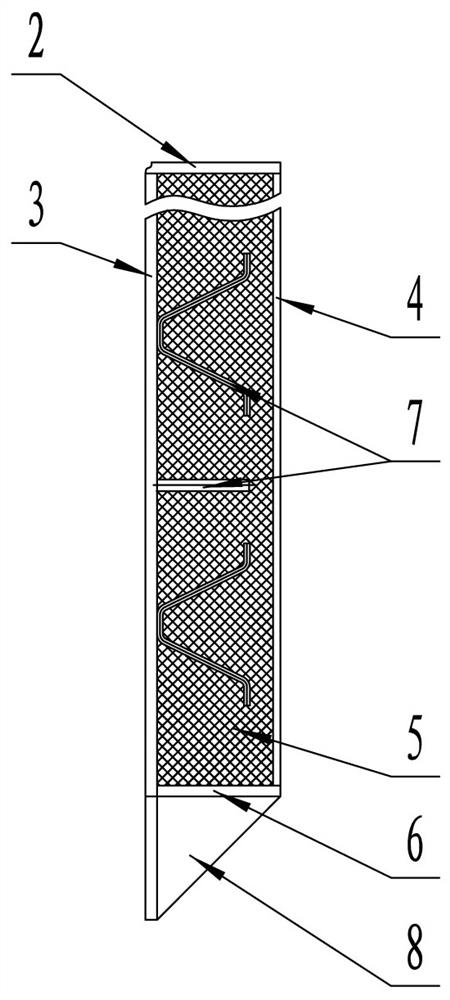

[0030] like Figure 1 to Figure 3 It is a double-chamber kiln preheating zone thermal insulation device manufactured by the double-chamber kiln preheating zone thermal insulation construction method. 6 and anchors 7, the outer wall and outer top of the kiln shell 3 are welded and fixed with uniformly arranged anchors 7, the anchors 7 are V-shaped anchors, and the angle between the arms of the V-shaped anchors is 30°~60° °, the end of the support arm has a bent portion that is bent outward, each anchor is perpendicular to the outer surface of the kiln shell, and the extension surfaces of two adjacent anchors are in a vertical and positive cross direction. The center distance a is 150 mm to 250 mm. The bottom of the kiln shell 3 is provided with a horizontal radially outward supporting plate 6 along the circumferential direction. The supporting plate 6 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com