Cable-stayed adhesive force tester

A technology of adhesion and tester, which is applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, instruments, etc., and can solve the problem of not being able to truly simulate asphalt pavement in high temperature and rainy areas loading mode etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

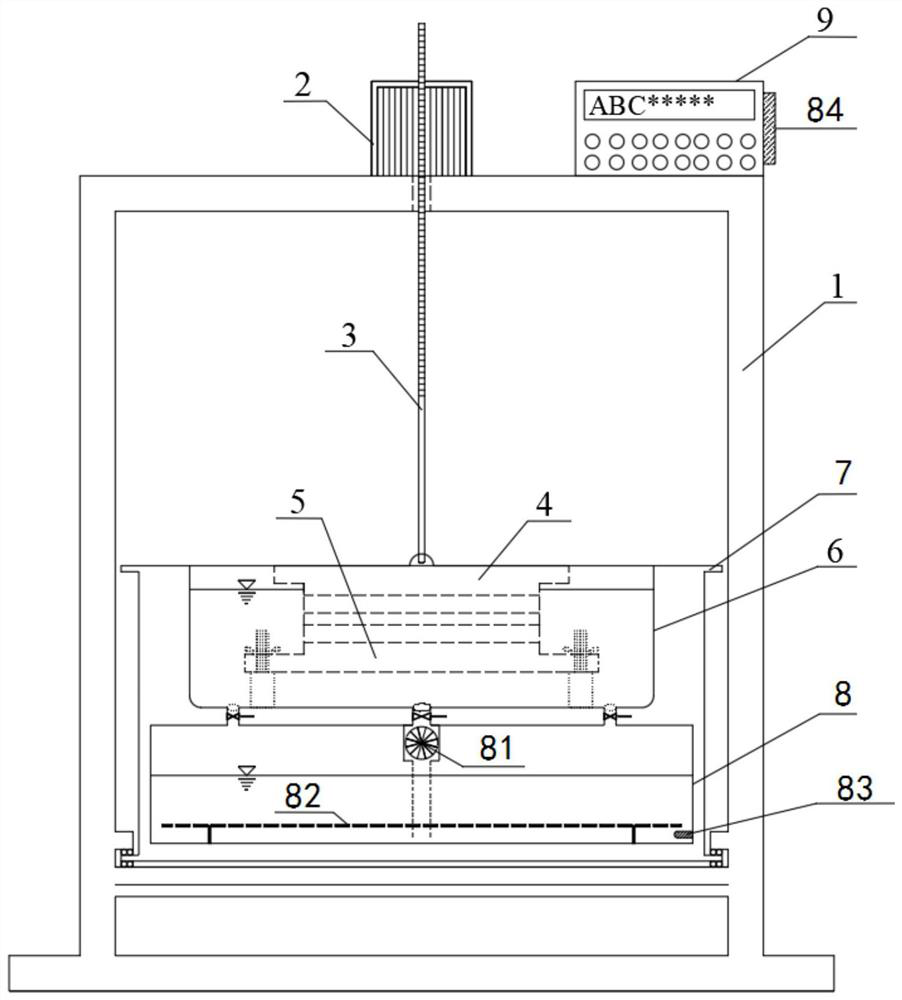

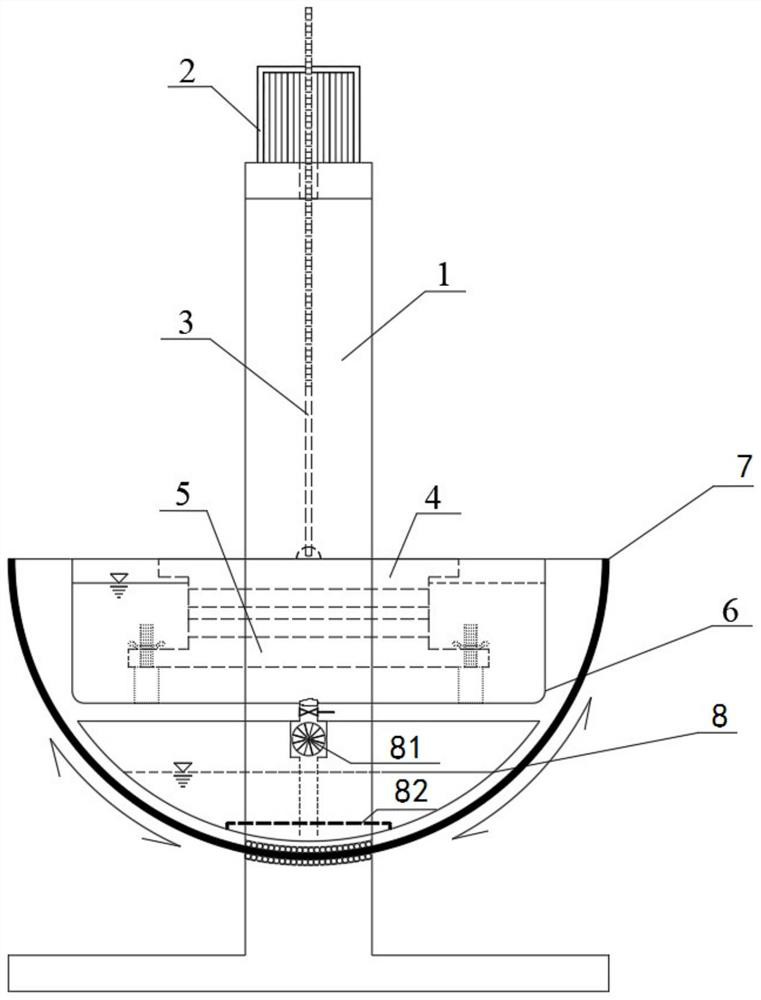

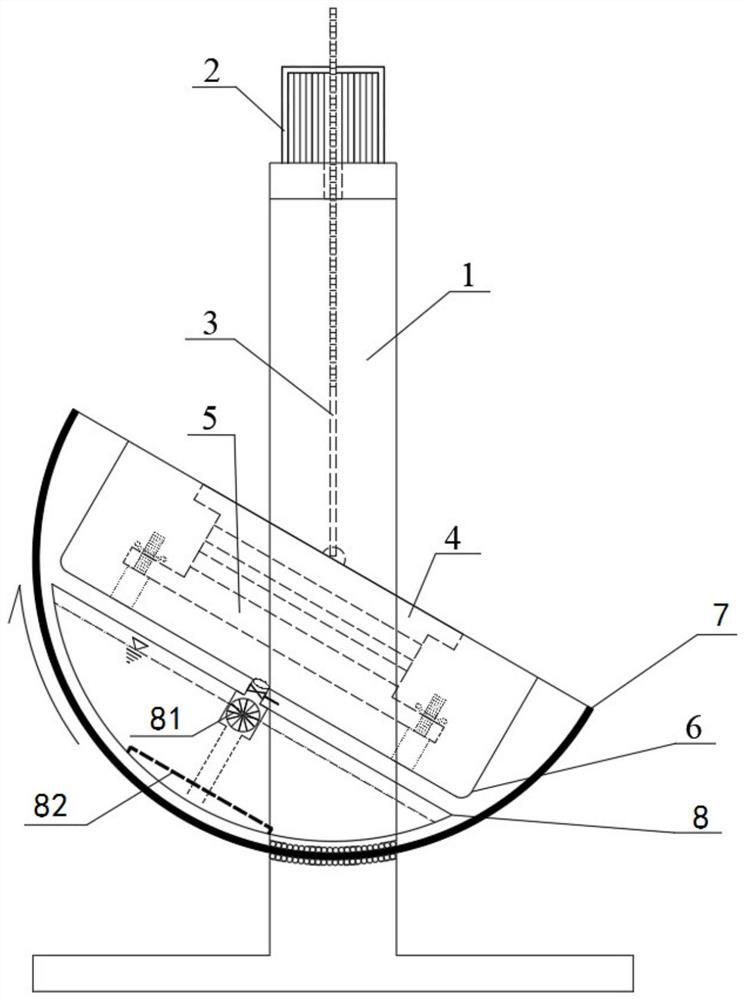

[0045] An oblique pull adhesion tester, comprising a frame 1, a tensioner 2, a pulling rod 3, an upper support plate 4, a lower support plate 5, a water bath container 6 and a rotating bracket 7; the tensioner 2 is installed on the top of the frame 1 In the middle position, the pulling rod 3 passes through the upper beam of the frame 1 and is connected downward to the upper support plate 4, the upper support plate 4 and the lower support plate 5 are the pieces to be tested, and the lower support plate 5 is fixedly installed in the water bath container 6. , the water bath container 6 is embedded in the rotating bracket 7 , and the rotating bracket 7 is slidably installed on the lower beam of the frame 1 .

[0046] The specimen to be tested is a specimen with a slate / upper cladding layer + cementitious material / bonding layer + slate / underlying layer structure. During the test, the water bath container 6 is used for water bath insulation, and the rotating bracket 7 is used to plac...

Embodiment 2

[0048] A diagonal pull adhesion tester, comprising: a frame 1, a tensioner 2, a pulling rod 3, an upper support plate 4, a lower support plate 5, a water bath container 6, a water storage heating container 8, a rotating bracket 7 and a controller 9. The tensioner 2 is installed in the middle position of the top of the frame 1. The pulling rod 3 passes through the upper beam of the frame 1 and is connected downward to the upper support plate 4. The test piece of cementitious material / bonding layer + slate / underlying layer structure, the lower support plate 5 is fixedly installed in the bottom middle position of the water bath container 6, the water bath container 6 is embedded in the upper part of the rotating support 7, the water storage heating container 8 It is installed at the lower part of the rotating support 7 directly below the water bath container 6, the rotating support 7 is slidably installed on the lower beam of the frame 1, the controller 9 is installed on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com