5G-based factory AGV device and control method thereof

A device control, 5G technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as difficulties in automated warehousing and transportation operations, meet the needs of fully automated warehousing and transportation operations, reduce labor costs, and promote intelligence. effect of the development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

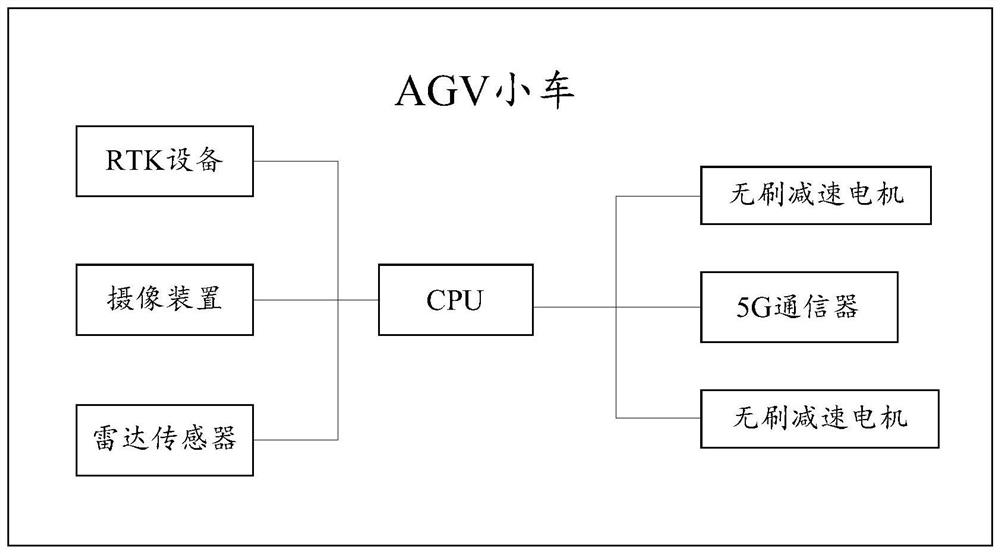

[0056] Embodiments of the present invention provide a 5G-based factory AGV device, such as figure 1 As shown, it mainly includes AGV car, camera device, RTK device, radar sensor, brushless gear motor, CPU and 5G communicator; camera device, RTK device, radar sensor, CPU and 5G communicator are all set on the AGV car; camera The output terminal of the device, RTK equipment and radar sensor is electrically connected to the input terminal of the CPU, the output terminal of the CPU is electrically connected to the control terminal of the brushless gear motor, and the rotor of the brushless gear motor is connected to the AGV trolley; the 5G communicator is electrically connected to the CPU. Connection; CPU receives transportation instructions and route planning information through the 5G communicator, RTK equipment locates the current position information of the AGV car, and the CPU drives the AGV car to drive according to the route planning information through the brushless gear mo...

Embodiment 2

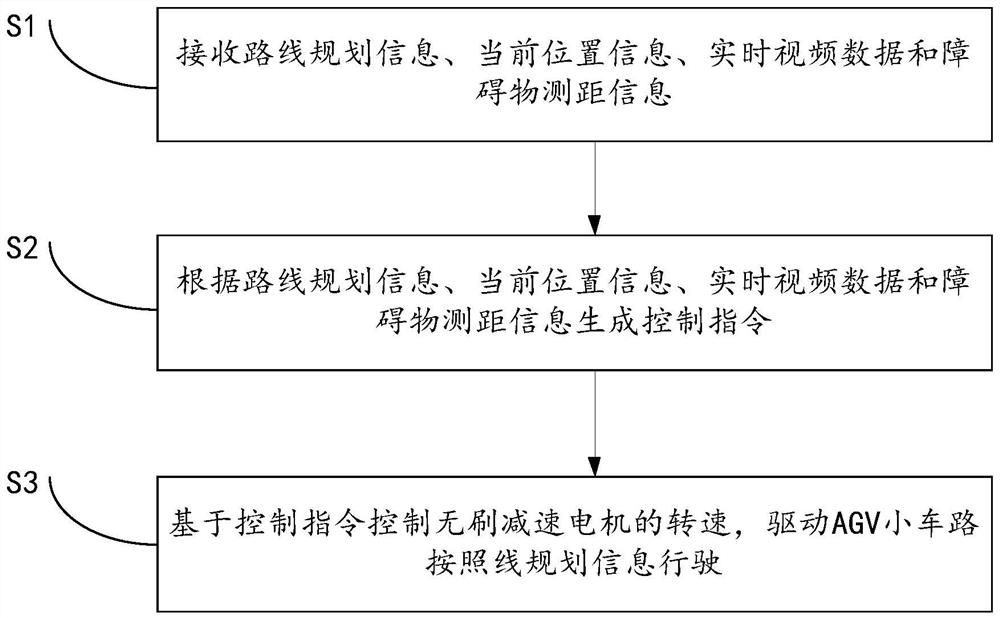

[0062] A 5G-based factory AGV device control method in an embodiment of the present invention is applied to the CPU provided in Embodiment 1, such as figure 2 The methods shown include:

[0063] S1: Receive route planning information, current location information, real-time video data and obstacle ranging information;

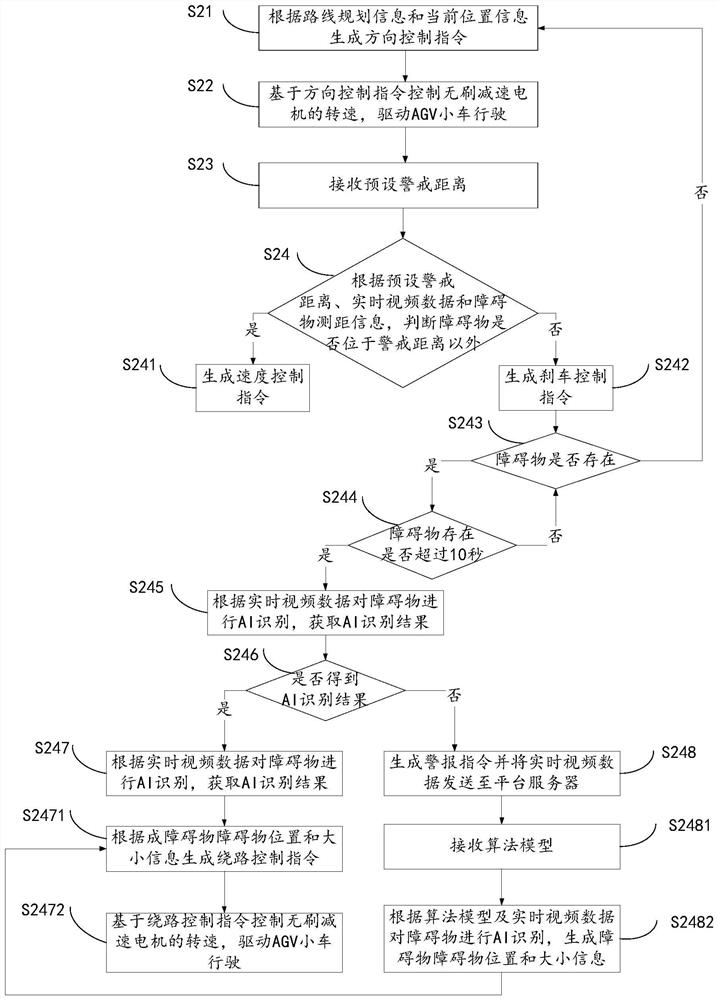

[0064] S2: Generate control instructions according to route planning information, current location information, real-time video data and obstacle ranging information;

[0065] S3: Control the speed of the brushless deceleration motor based on the control command, and drive the AGV car to travel according to the line planning information.

[0066] The platform server is deployed in the dispatching room of the factory, and can view the video, working status, load status, and location information of each AGV car in real time; the video materials of obstacles in the factory have been collected and downloaded to the AVG car after training by the server's deep lear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com