Monitoring and early warning method and system for special steel production workshop

A production workshop and special steel technology, applied in manufacturing computing systems, alarms, data processing applications, etc., can solve the problems of low efficiency, poor timeliness, and low accuracy of special steel production quality monitoring, reducing manual participation, Reduce labor costs and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

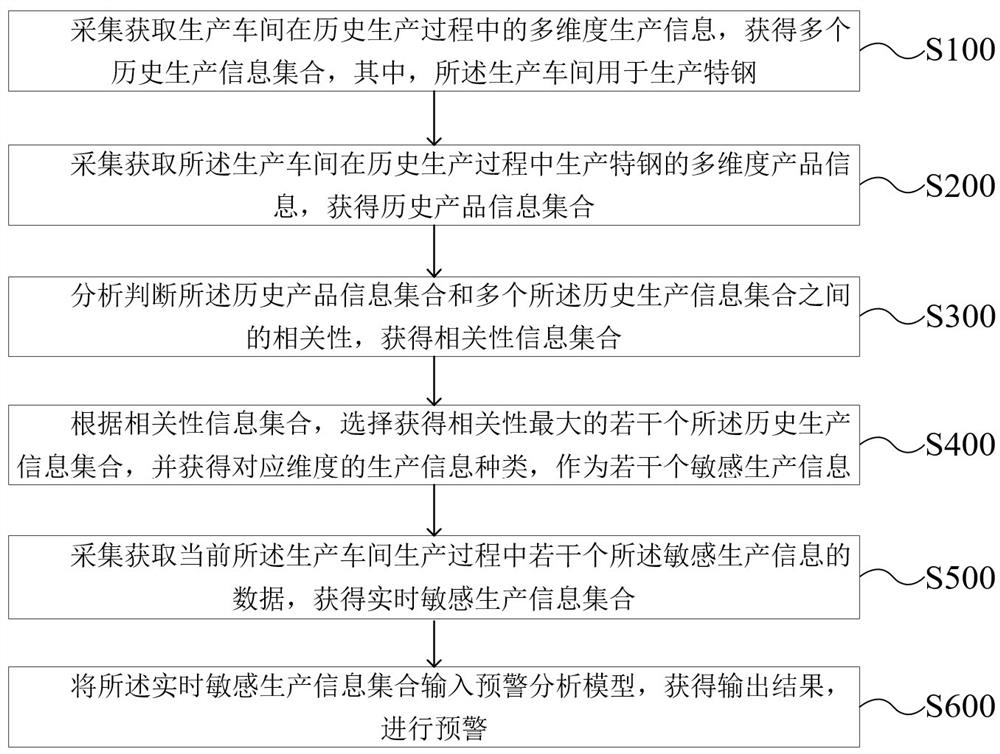

[0019] like figure 1 As shown, the present application provides a monitoring and early warning method for a special steel production workshop, the method comprising:

[0020] S100: Collect and obtain multi-dimensional production information of a production workshop in a historical production process, and obtain a plurality of historical production information sets, wherein the production workshop is used to produce special steel;

[0021] In the embodiment of the present application, the production workshop is any special steel production workshop used for special steel production, and the production workshop may include any one or more production processes in the production process of any type of special steel, exemplarily, may include Any process such as smelting, heat treatment, and forging.

[0022] The special steel produced by the production workshop can be any type of special steel in the prior art, for example, the special steel can be any grade of bearing steel, high...

Embodiment 2

[0117] Based on the same inventive concept as the monitoring and early warning method of a special steel production workshop in the foregoing embodiment, such as Figure 4 As shown, the application provides a monitoring and early warning system for a special steel production workshop, wherein the system includes:

[0118] The production information collection module 11 is used to collect and obtain multi-dimensional production information of the production workshop in the historical production process, and obtain a plurality of historical production information sets, wherein the production workshop is used for producing special steel;

[0119] The product information collection module 12 is used to collect and obtain the multi-dimensional product information of the special steel produced by the production workshop in the historical production process, and obtain a collection of historical product information;

[0120] The correlation analysis module 13 is used for analyzing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com