Tea and bamboo mixed cigarette and manufacturing method thereof

A technology of tea bamboo and cigarettes, which is applied in the fields of tobacco, tobacco preparation, and paper cigarette manufacturing. It can solve the problems of human health hazards, smoke-free odor, etc., and achieve the effects of suppressing poison, easy to burn, and loose structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

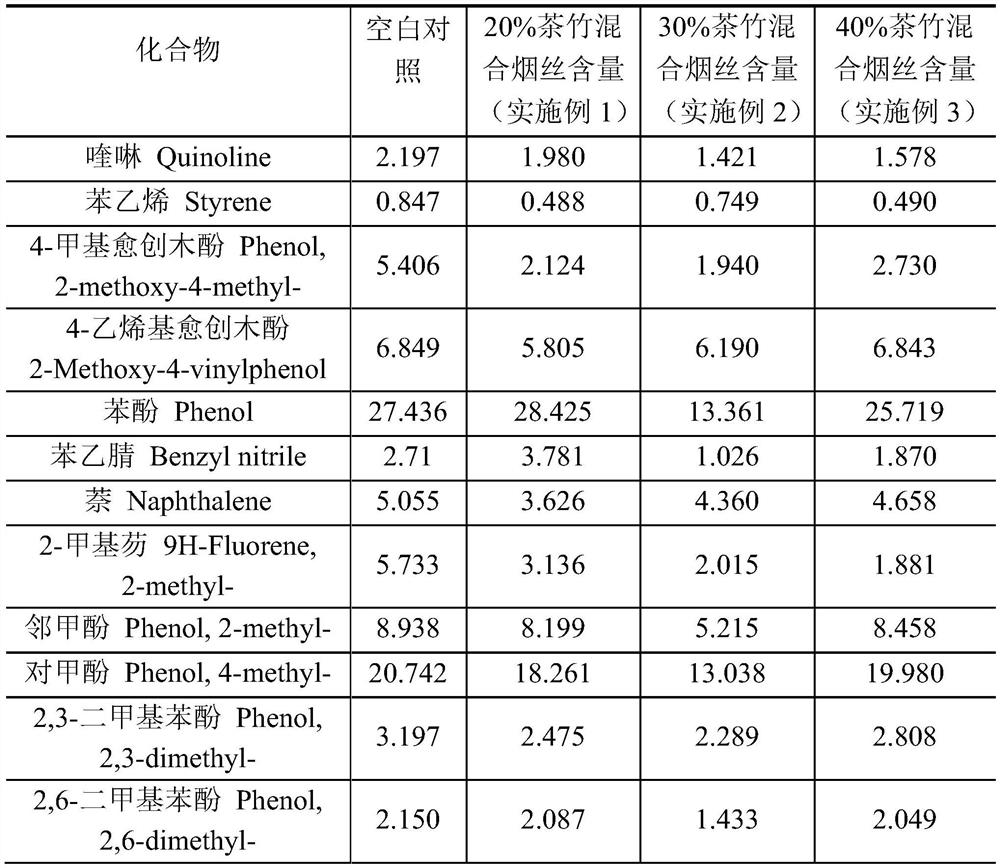

Embodiment 1

[0024] A tea-bamboo mixed cigarette, comprising the following components by weight: 20 parts of tea-bamboo mixed cut tobacco and 80 parts of common reconstituted tobacco; the tea-bamboo mixed cut tobacco comprises the following components by weight: 35 parts of Pu'er tea, 45 parts of pale bamboo leaves, 18 parts of alcohol and 2 parts of pectin solution with a concentration of 2 wt%.

[0025] The preparation method of above-mentioned tea bamboo mixed cigarette,

[0026] Include the following steps:

[0027] (1) Pulverize Pu'er tea and pale bamboo leaves to 70 meshes, add 50% of their total mass into 50°C warm water, and stir to form a uniform slurry, then add atomizer and adhesive, and then heat at 65°C Vacuum drying and dehydration;

[0028] (2) pressing the dehydrated material into a thickness of 2 mm, and then drying and shredding to obtain a tea-bamboo mixed shredded tobacco with a water content of 12%;

[0029] (3) After mixing the tea bamboo mixed shredded tobacco and...

Embodiment 2

[0031] A tea-bamboo mixed cigarette, comprising the following components by weight: 30 parts of tea-bamboo mixed cut tobacco and 70 parts of common reconstituted tobacco; the tea-bamboo mixed cut tobacco comprises the following components by weight: 20 parts of Pu'er tea, 30 parts of pale bamboo leaves, 15 parts of alcohol and 1 part of pectin solution with a concentration of 2 wt%.

[0032] The preparation method of above-mentioned tea bamboo mixed cigarette,

[0033] Include the following steps:

[0034] (1) pulverize Pu'er tea and pale bamboo leaves to 50 mesh, then add 45% of its total mass into 40°C warm water, and stir to form a uniform slurry, then add atomizer and adhesive, and then heat at 60°C Vacuum drying and dehydration;

[0035] (2) pressing the dehydrated material into a thickness of 2 mm, and then drying and shredding to obtain a tea-bamboo mixed shredded tobacco with a water content of 10%;

[0036] (3) After mixing the tea bamboo mixed shredded tobacco and...

Embodiment 3

[0038] A tea-bamboo mixed cigarette, comprising the following components by weight: 40 parts of tea-bamboo mixed cut tobacco and 60 parts of common reconstituted tobacco; the tea-bamboo mixed cut tobacco comprises the following components by weight: 25 parts of Pu'er tea, 35 parts of pale bamboo leaves, 20 parts of alcohol and 5 parts of pectin solution with a concentration of 2 wt%.

[0039] The preparation method of above-mentioned tea bamboo mixed cigarette,

[0040] Include the following steps:

[0041] (1) pulverize Pu'er tea and pale bamboo leaves to 90 mesh, add 55% of its total mass into 60°C warm water, and stir to form a uniform slurry, then add atomizer and adhesive, and then heat at 75°C Vacuum drying and dehydration;

[0042] (2) pressing the dehydrated material into a thickness of 2 mm, and then drying and shredding to obtain a tea-bamboo mixed shredded tobacco with a water content of 15%;

[0043] (3) After mixing the tea bamboo mixed shredded tobacco and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com