Auxiliary device for assembling star wheel roller and spring of isolator

An auxiliary device and one-way device technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems that affect the progress of assembly, affect assembly accuracy, spring angle deviation, etc., achieve fast production efficiency and ensure assembly accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

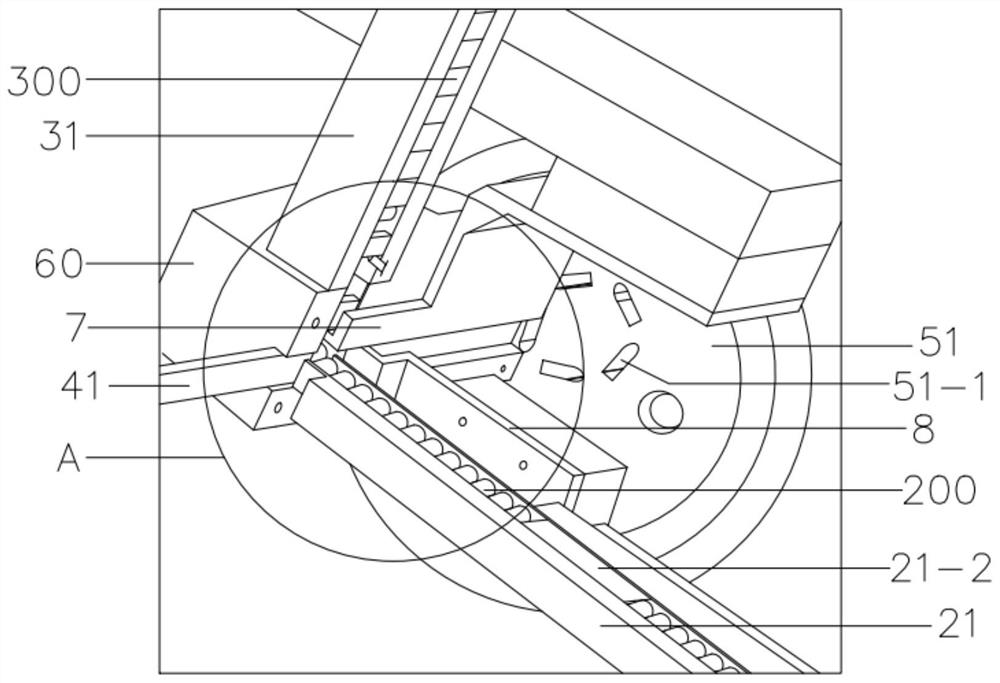

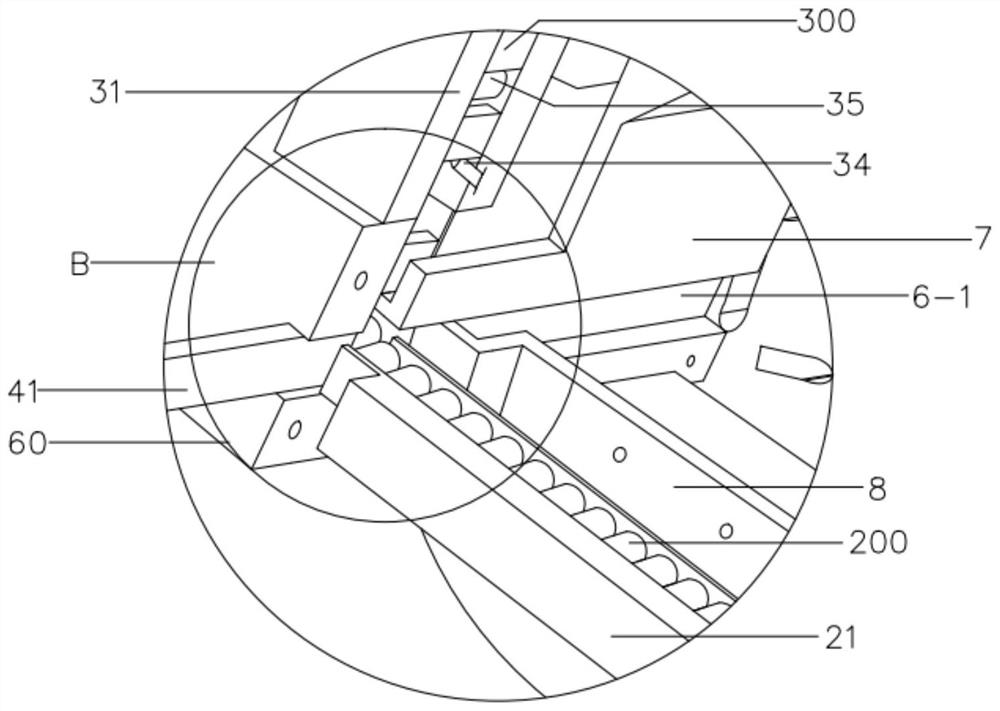

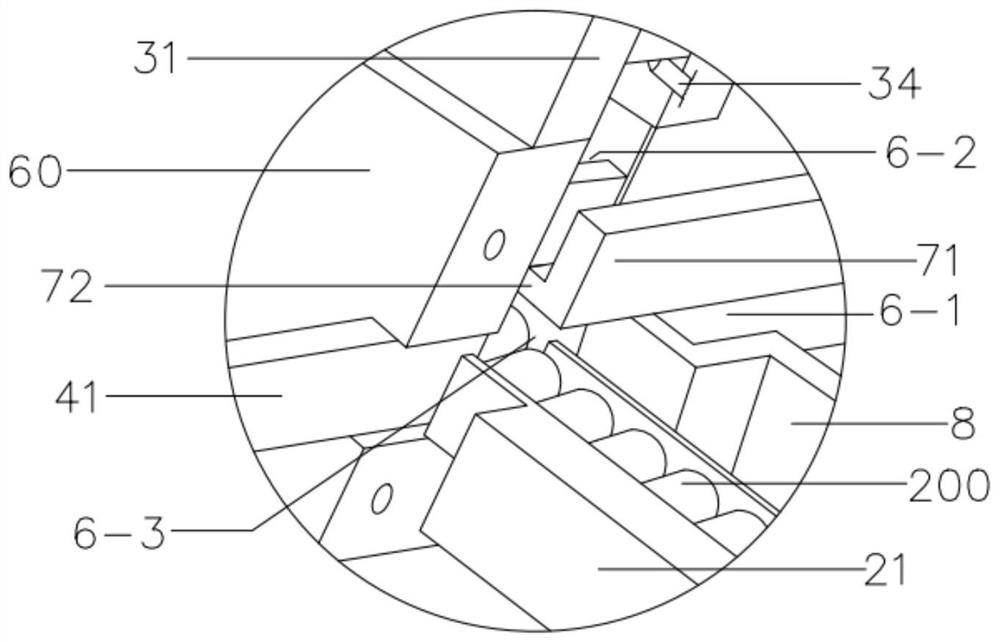

[0030] Attached below Figure 1-6 The technical solutions in the present invention are further described with the examples.

[0031] like Figure 1-6 As shown in the figure, an auxiliary device for assembling a one-way star wheel roller and a spring includes a distribution component and a pre-assembled component that are both arranged on the work surface where the installation frame is located. The distribution component and the pre-assembled component are used for The spring conveying rails 31 for conveying the springs 300 in a state of abutting with each other are connected, and the distributing assembly includes at least two limiters that are driven by the driving mechanisms to separate the springs 300 in the spring conveying rails 31 individually and sequentially. The pre-assembled assembly includes a compression member 7 for compressing a single spring 300 processed through the limiting member and a pre-assembly groove 6 communicating with the spring conveying track 31 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap