Vacuum-pumping processing method for culture dish

A processing method and petri dish technology, which are applied in the directions of pressurized/gasified packaging, transportation packaging, packaging, etc., can solve the problem of insufficient production and processing efficiency, and achieve the effect of improving production and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] like Figure 1-Figure 5 As shown, the vacuum processing method of the petri dish of the present invention comprises the following steps:

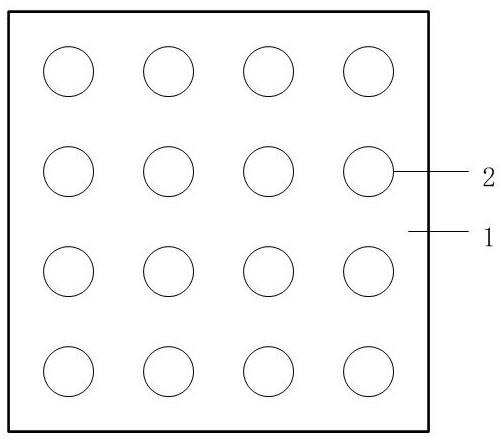

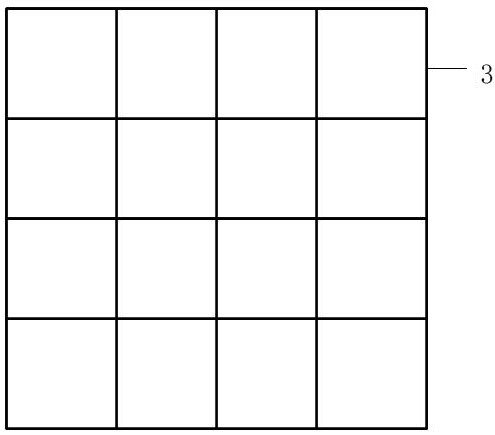

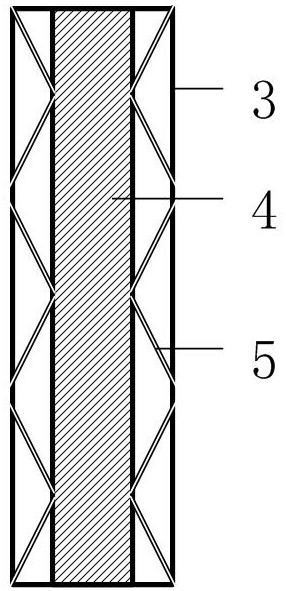

[0030] S1. Prepare a bottom mold 6 with a plurality of evenly distributed grooves 2, a plastic bottom film 1 with a plurality of uniformly distributed grooves 2, a coating film of the same size and material as the bottom film 1, and the bottom film 1 The plastic partition frame 3 divided into a plurality of rectangular areas, and the electric heating device that can be pressed down; the middle part of the beam constituting the partition frame 3 is a groove, and the two sides are Y-shaped wings, and the groove is provided with Hot melt adhesive 4, the wing portion has a flow channel 5 that communicates the outer side of the groove and the beam;

[0031] S2. place the bottom film 1 on the bottom mold 6, and place the groove 2 of the bottom film 1 in the corresponding groove of the bottom mold 6;

[0032] S3. The partition frame 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com