Silver tin nano material conductive silver paste and application thereof in vacuum glass

A technology of nanomaterials and conductive silver paste, which is applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problems of high sintering temperature of conductive silver paste, uneven distribution of silver and tin, and achieve dispersion Good performance, lower melting temperature, and precise element ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

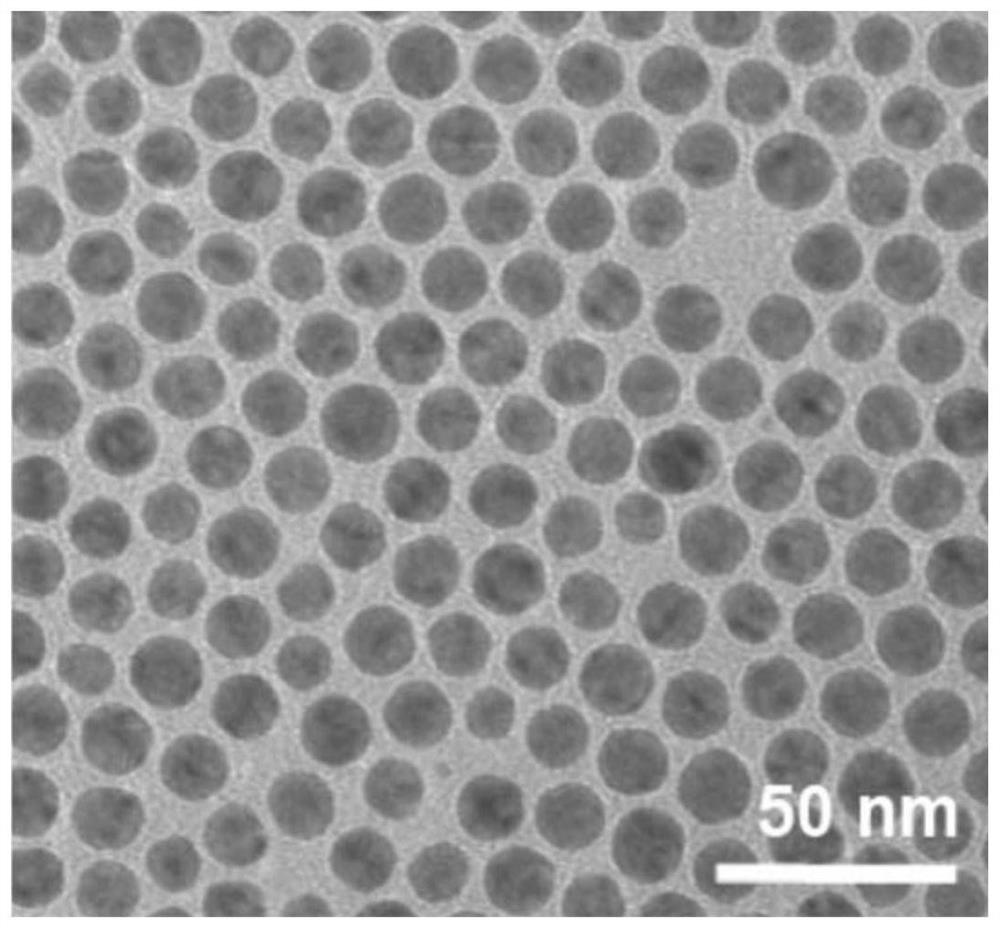

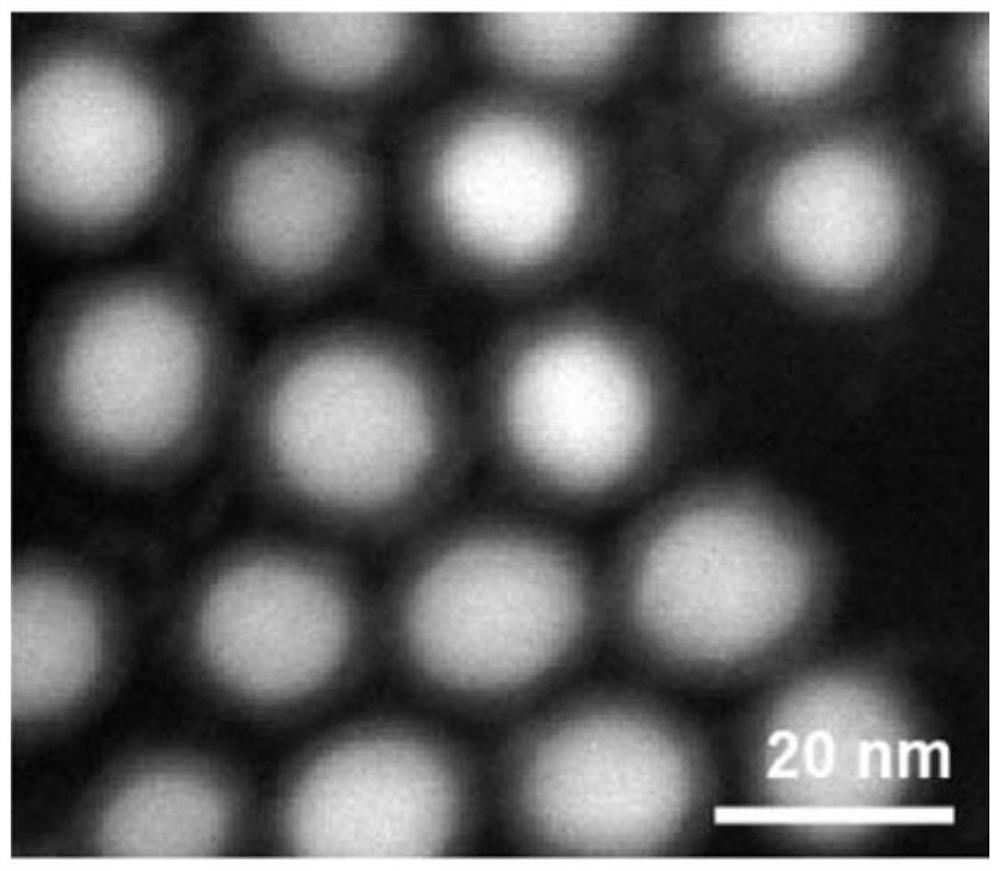

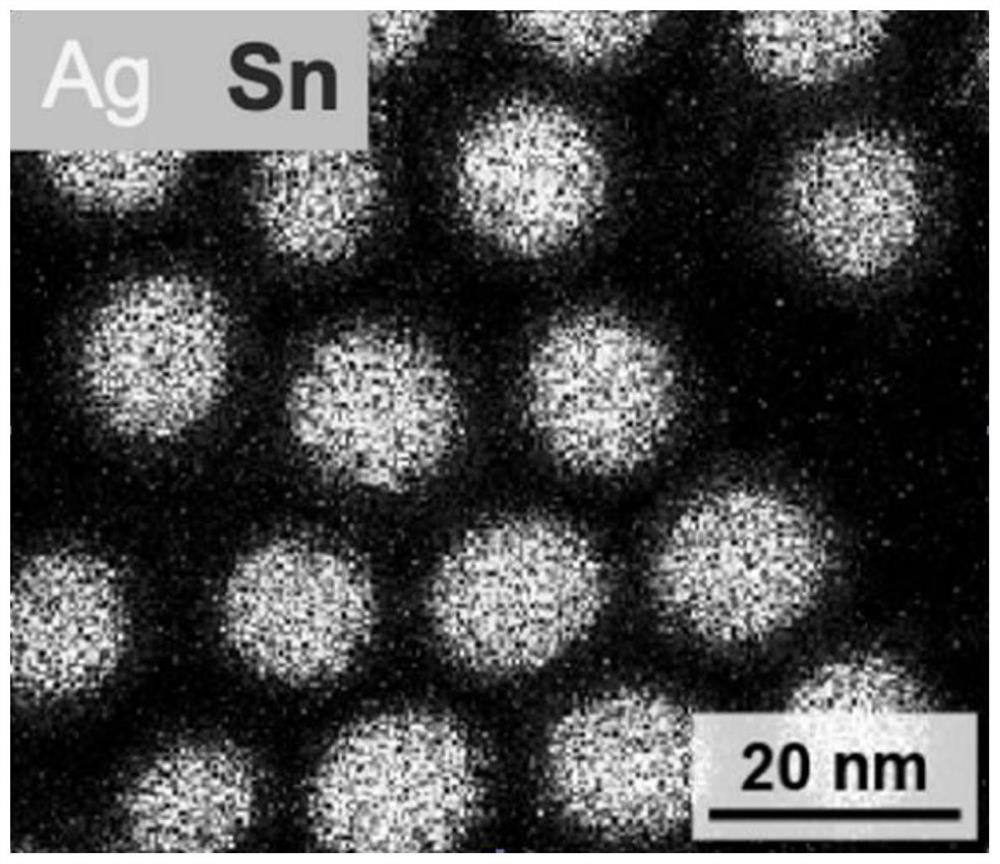

[0039] A silver-tin nanomaterial conductive silver paste, including silver-tin nano-alloy, glass powder, dispersant and thickener, silver-tin nano-alloy includes silver source and tin source, silver source is made into nano-silver balls first, and then tin The source is coated on the nano-silver ball. Specifically adopt the following method to prepare:

[0040] Step 1: Add 0.2 mol of silver nitrate to 4L of oleylamine solution, raise the temperature to 90°C, and stir for 10 minutes to fully dissolve the silver nitrate to obtain a silver precursor;

[0041] Step 2, transfer the silver precursor to the flask, feed argon gas to exhaust the air in the flask and seal the flask, then raise the temperature to 180°C and keep it for 60 minutes to obtain the nano-silver seed dispersion;

[0042] Step 3, dissolving 0.023mol of tin tetrachloride in 2.5L of squalane, slowly adding it to the nano-silver seed dispersion in step 2, and raising the temperature to 300°C, keeping it for 10 minu...

Embodiment 2

[0049] A conductive silver paste of silver-tin nanomaterials, comprising silver-tin nano-alloy, glass powder, dispersant and thickener, prepared by the following method:

[0050] Step 1: Add 0.2 mol of silver nitrate to 4L of oleylamine solution, raise the temperature to 60°C, and stir for 30 minutes to fully dissolve the silver nitrate to obtain a silver precursor;

[0051]Step 2, transfer the silver precursor to the flask, feed argon gas to exhaust the air in the flask and seal the flask, then raise the temperature to 200°C and keep it for 30 minutes to obtain the nano-silver seed dispersion;

[0052] Step 3, dissolving 0.023mol of tin tetrachloride in 2.5L of squalane, slowly adding to the nano-silver seed dispersion in step 2, and raising the temperature to 250°C, keeping it for 30 minutes to obtain a silver-tin nano-alloy the dispersion liquid;

[0053] Step 4, after the dispersion liquid of the silver-tin nano-alloy is naturally cooled to room temperature, absolute etha...

Embodiment 3

[0057] A conductive silver paste of silver-tin nanomaterials, comprising silver-tin nano-alloy, glass powder, dispersant and thickener, prepared by the following method:

[0058] Step 1: Add 0.2 mol of silver nitrate to 4L of oleylamine solution, raise the temperature to 75°C, and stir for 20 minutes to fully dissolve the silver nitrate to obtain a silver precursor;

[0059] Step 2, transfer the silver precursor to the flask, feed argon gas to exhaust the air in the flask and seal the flask, then raise the temperature to 150°C and keep it for 80 minutes to obtain the nano-silver seed dispersion;

[0060] Step 3, dissolve 0.023mol of tin tetrachloride in 2.5L of squalane, slowly add to the nano silver seed dispersion in step 2, and heat up to 300°C, keep for 20 minutes to obtain silver tin nano alloy the dispersion liquid;

[0061] Step 4, after the dispersion liquid of the silver-tin nano-alloy is naturally cooled to room temperature, absolute ethanol is added to precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com