Thermal cutting device for woven bags

A technology of thermal cutting and woven bags, applied in the field of plastic product manufacturing, can solve the problems of plastic thin strips detachment, low processing efficiency, disintegration of woven bags, etc., to avoid movement, improve processing efficiency, and avoid disintegration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

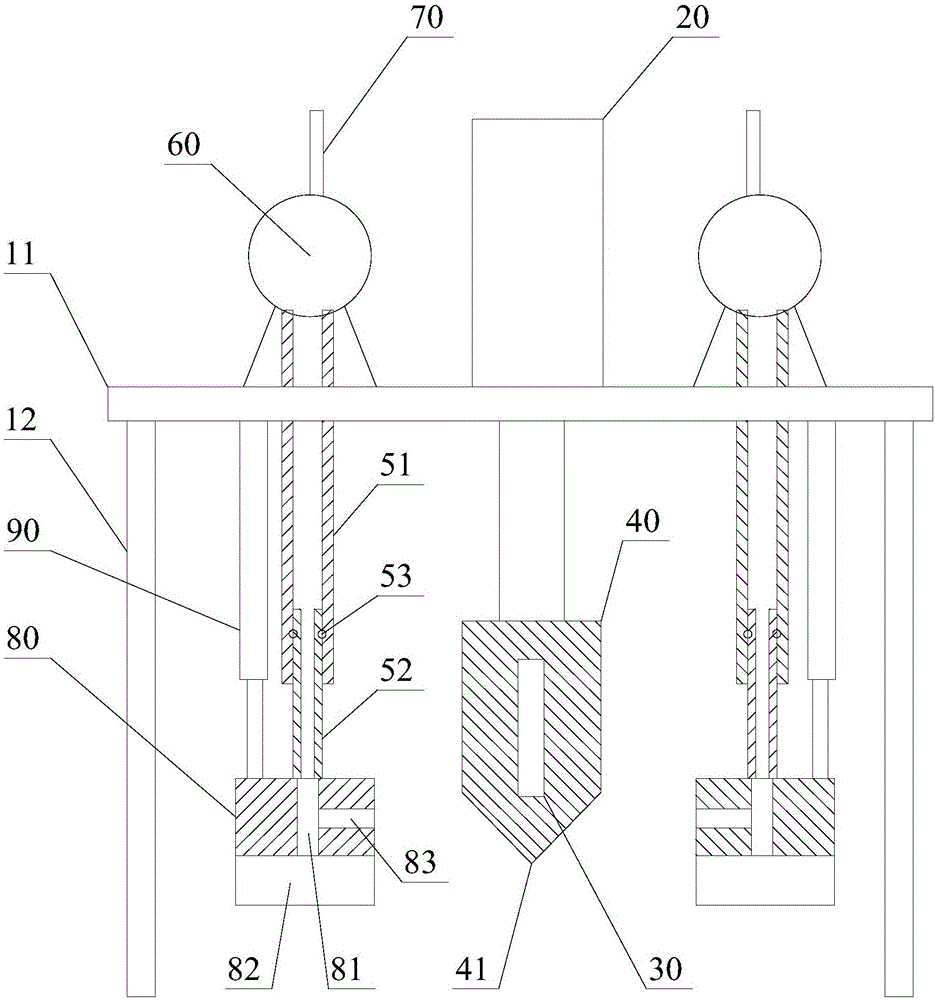

[0027] Such as figure 1 As shown, the thermal cutting equipment for woven bags includes a top plate 11, a pillar 12, a pneumatic cylinder 20, an electric heating block 30, a cutting knife 40, a first suction pipe 51, a second suction pipe 52, an air pump 60, and an exhaust Pipe 70, suction air block 80 and telescopic cylinder 90;

[0028] A plurality of the pillars 12 are vertically connected to the lower surface of the top plate 11 to support the top plate 11; the pneumatic cylinder 20 is fixed on the upper surface of the top plate 11; the piston rod of the pneumatic cylinder 20 It penetrates the top plate 11 from top to bottom and is connected to a cutting block 40 located below the top plate 11; the bottom of the cutting block 40 is provided with a cutting edge 41; the electric heating block 30 is arranged in the cutting block 40;

[0029] The air pump 60 is fixed on the top plate 11, the inlet of the air pump 60 is connected to one end of the first suction pipe 50, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com