Ampoule bottle producing and processing device and method

A processing device and technology for ampoules, which are used in glass production, packaging, bottling machines, etc., can solve the problems of easy drawing, raised and sharp tops of ampoules, etc., to prevent sticking, facilitate heat dissipation, and prevent waste and pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to specific embodiments.

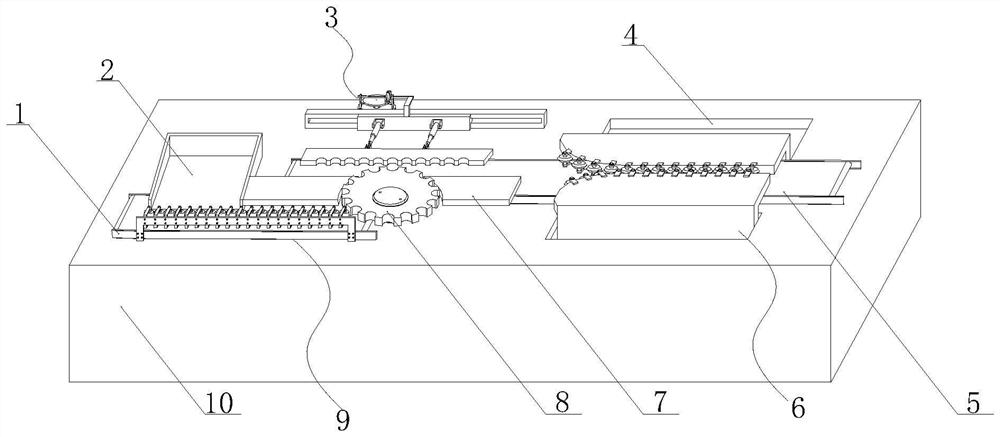

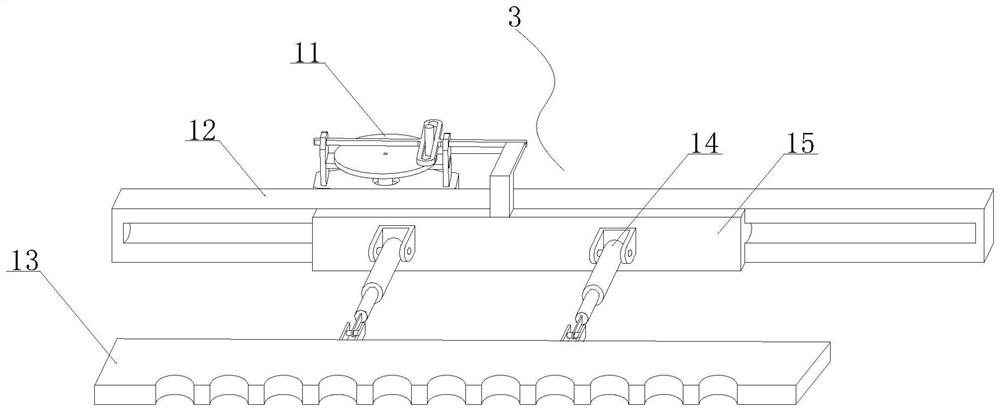

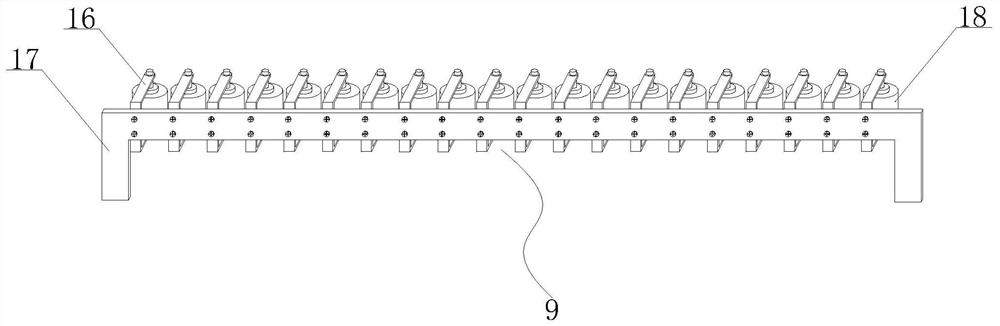

[0030] showing figure 1 A production and processing device for ampoules provided in , including a workbench 10 for carrying the weight of all components of the device and providing installation points for other mechanisms, the upper surface of the workbench 10 is provided with a first conveyor belt 1 for conveying ampoules , and the upper rear position of the first conveyor belt 1 is equipped with a concentration plate 2 for temporarily placing ampoules, and the side of the lower port of the concentration plate 2 is provided with a set of non-contact baffle plates 7 for blocking the ampoules and preventing the ampoules from being overturned. , and between the baffles 7 is embedded a turntable 8 for separating the ampoules, while the lower port of the central disc 2 is provided with a limit mechanism 9 extending to the edge of the turntable 8 for constraining the ampoules. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com