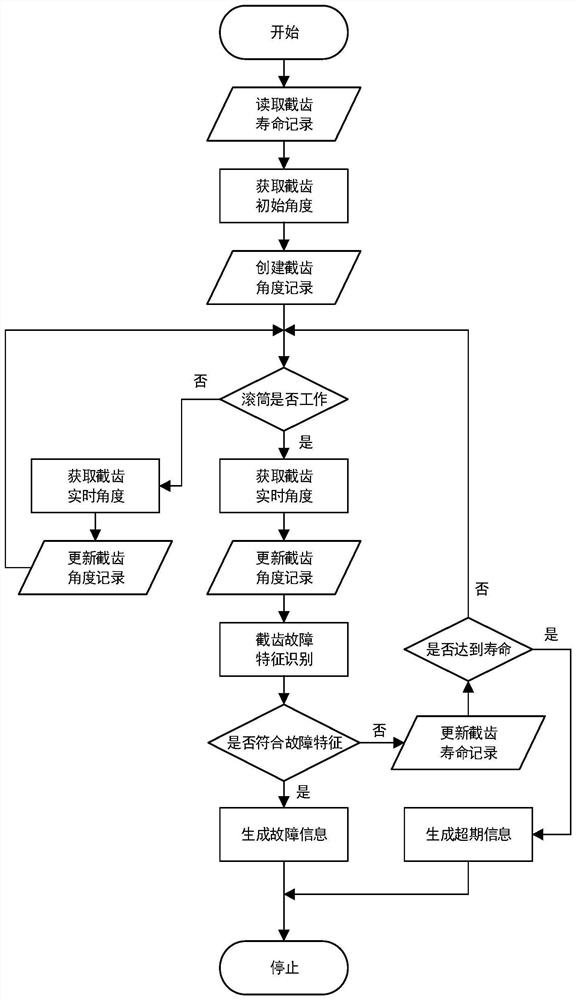

Pick fault detection method, detection device and use method

A technology of fault detection and cutting teeth, which is applied in the direction of measuring devices, mining devices, cutting machinery, etc., can solve the problems that affect the coal breaking efficiency of the shearer, the poor working conditions, and the working of the coal mining drum with diseases, so as to achieve long-term prevention The effect of working with sickness in time, avoiding overdue service, and reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

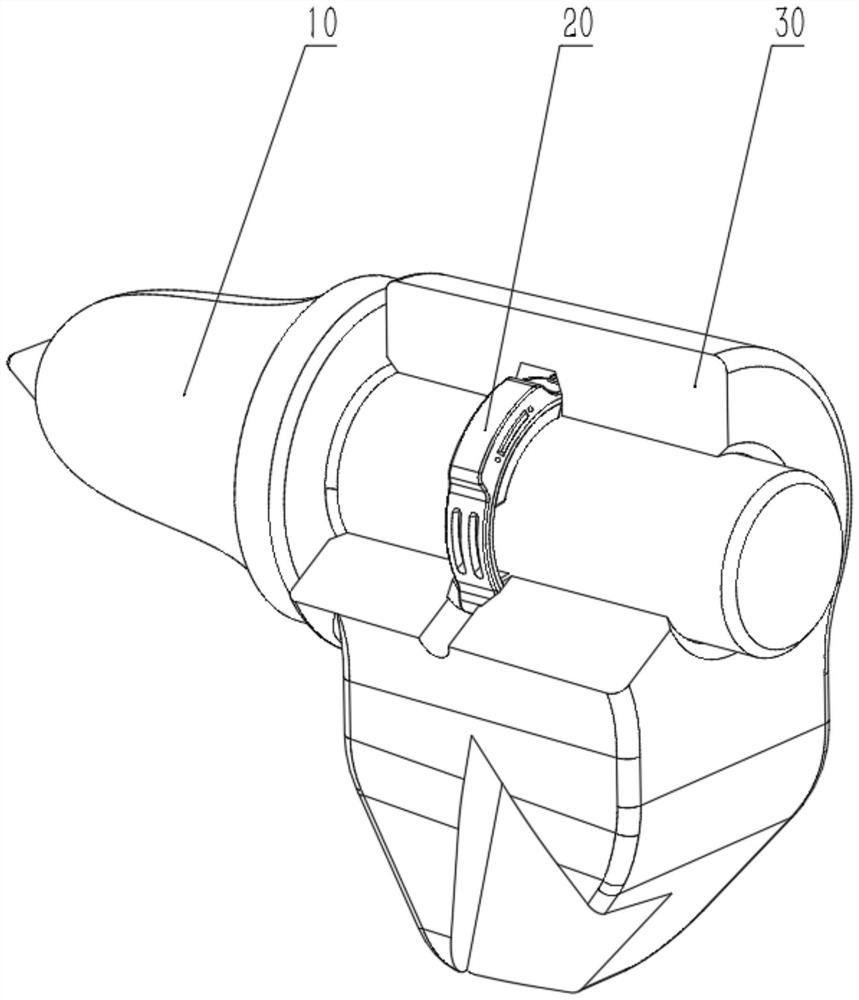

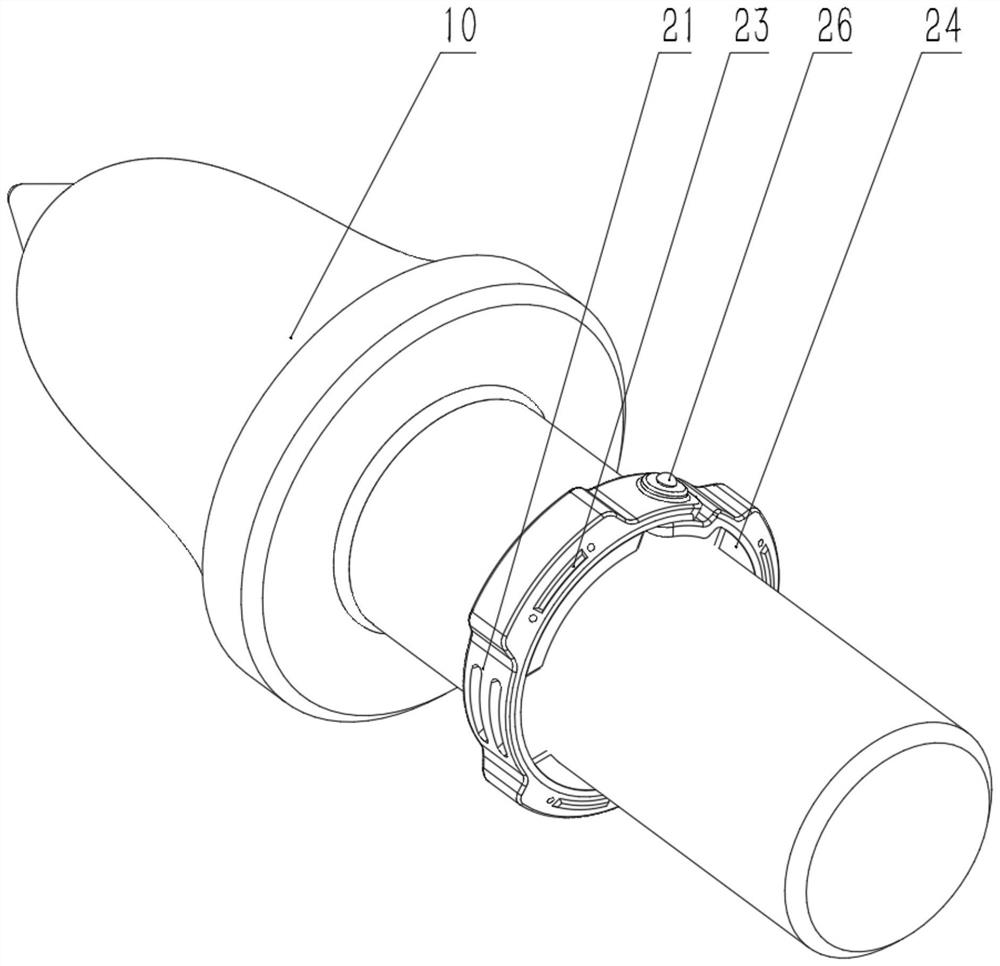

[0024] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0025] In the present invention, unless otherwise expressly specified and limited, the terms "installed", "connected", "connected", "fixed" and other terms should be understood in a broad sense, for example, it may be a fixed connection or a detachable connection , or integrated; it can be directly connected or indirectly connected through an intermediate medium, and it can be the internal connection of two elements or the interaction relationship between the two elements. For those of ordinary skill in the art, the specific meanings of the above terms in the present invention can be understood according to specific situations.

[0026] In the description of the present invention, it should be understood that the terms "center", "length", "upper", "lower", "front", "rear", "left", "right", "vertical", The orientation or positional relationship indicated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com