Through-flow turbine device with bent groove

A technology of tubular water turbines and curved grooves, applied in the direction of reaction engines, mechanical equipment, hydroelectric power generation, etc., can solve the problems affecting the overall efficiency of water turbines, increase the maintenance cost of water turbines, and affect the stable operation of units, so as to solve the blade tip clearance Effects of cavitation, solution to pressure pulsation, and reduction of green strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

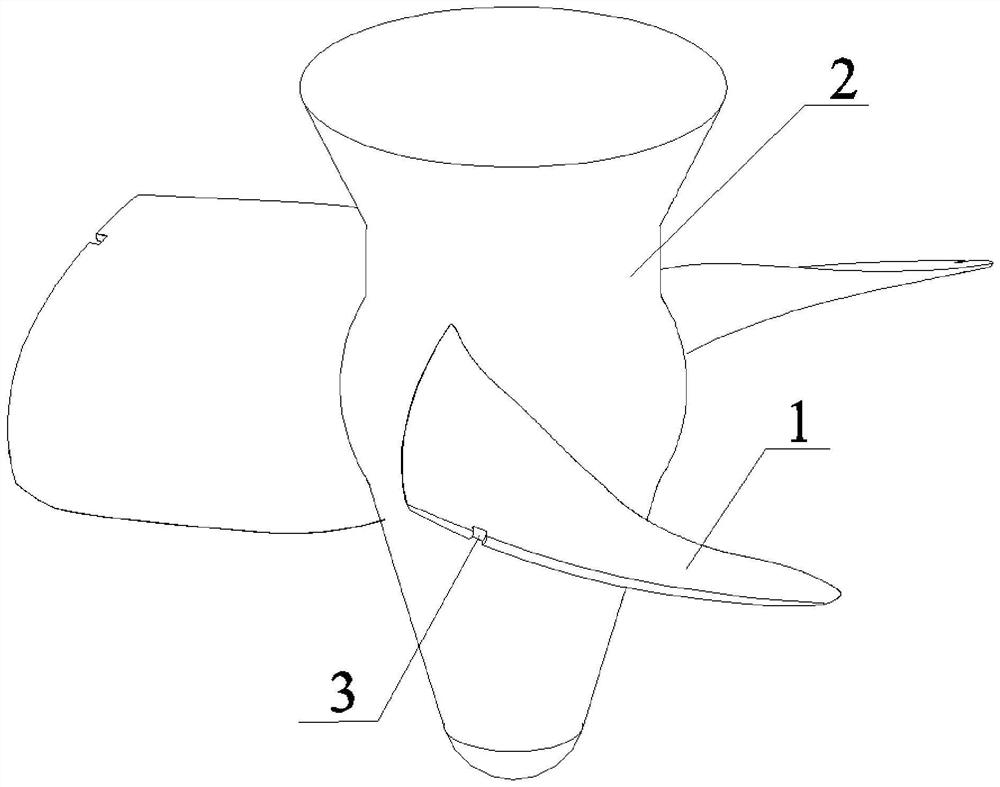

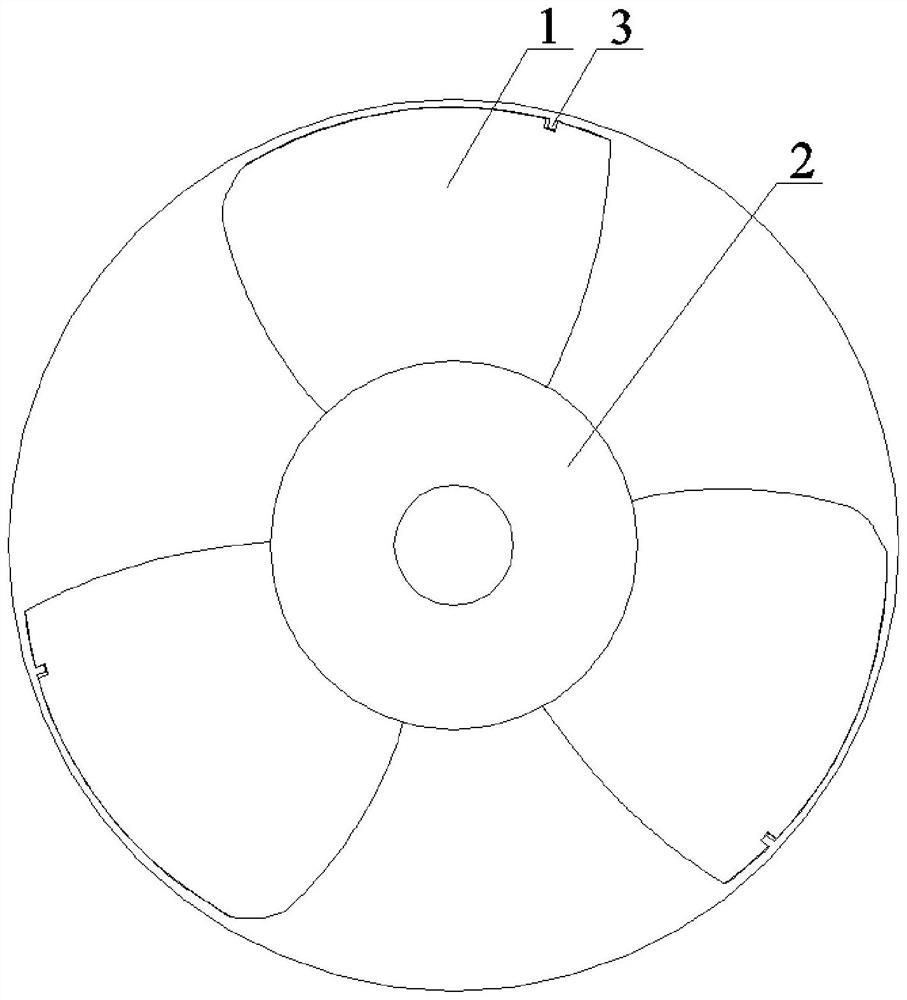

[0018] The tubular water turbine device with curved grooves of the present invention has a structure as follows: Figure 1-2 As shown, it includes a hub 2, the outer wall of the hub 2 is fixed with a plurality of blades 1 along its circumferential direction, the surface of each blade 1 is provided with a curved groove 3, and the curved groove 3 is arranged in the gap between the blade 1 and the inner wall of the runner. On the side, the curved groove 3 is opened on the edge of the blade 1 .

[0019] The blade 1 has a pressure surface and a suction surface. Under the condition that the rest of the geometry is kept unchanged, a curved groove 3 is made to pass through the pressure surface and the suction surface on the edge of the blade 1 at the gap position.

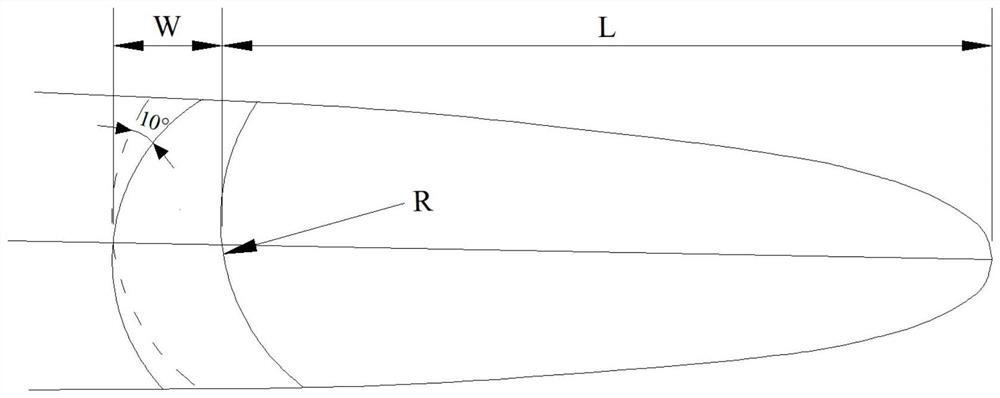

[0020] The right profile line of the curved groove 3 is set at a position 15% of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com