A method of growing high-quality silicon carbide crystals in an oxygen-containing atmosphere

A quality silicon carbide, silicon carbide technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of micropipe defects, crystal quality deterioration, inclusion defects, etc., to improve yield and reduce packaging Defects and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

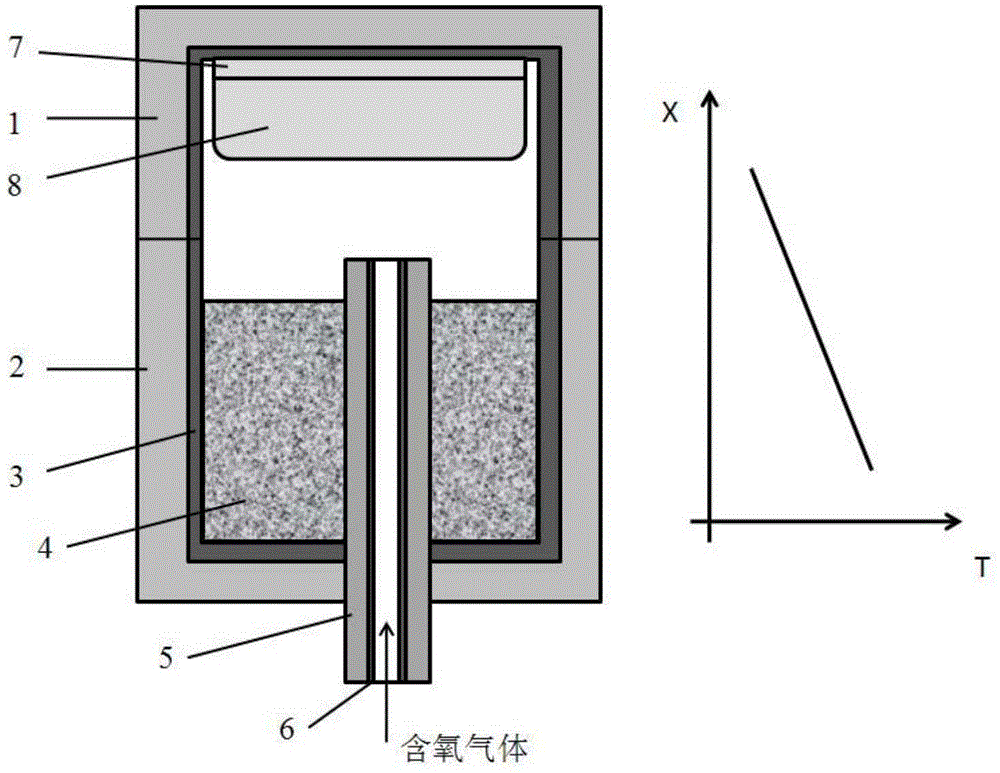

[0036] A piece of 4H-SiC seed crystal with a diameter of 100 mm, and the C plane is selected as the crystal growth plane. The schematic diagram of the growth chamber structure is shown in figure 2 , The inner side of the graphite crucible and the inner side of the graphite pipe are coated with TaC coating. The temperature at the raw material is set at 2200-2300°C, and the temperature at the seed crystal is 150°C lower than that of the raw material. During the growth process, the flow rate of Ar was 60 sccm outside the growth chamber, and the mixed gas of oxygen and carbon dioxide was passed into the growth chamber through graphite pipes. The volume mixing ratio of oxygen and carbon dioxide was 1:1, and the flow rate of the mixed gas of oxygen and carbon dioxide was constant during the growth process 10 sccm, one 4H-SiC crystal was grown. Cut and process the crystal into a 4-inch SiC wafer with a thickness of 500 microns, and use an optical microscope to detect the number of...

Embodiment 2

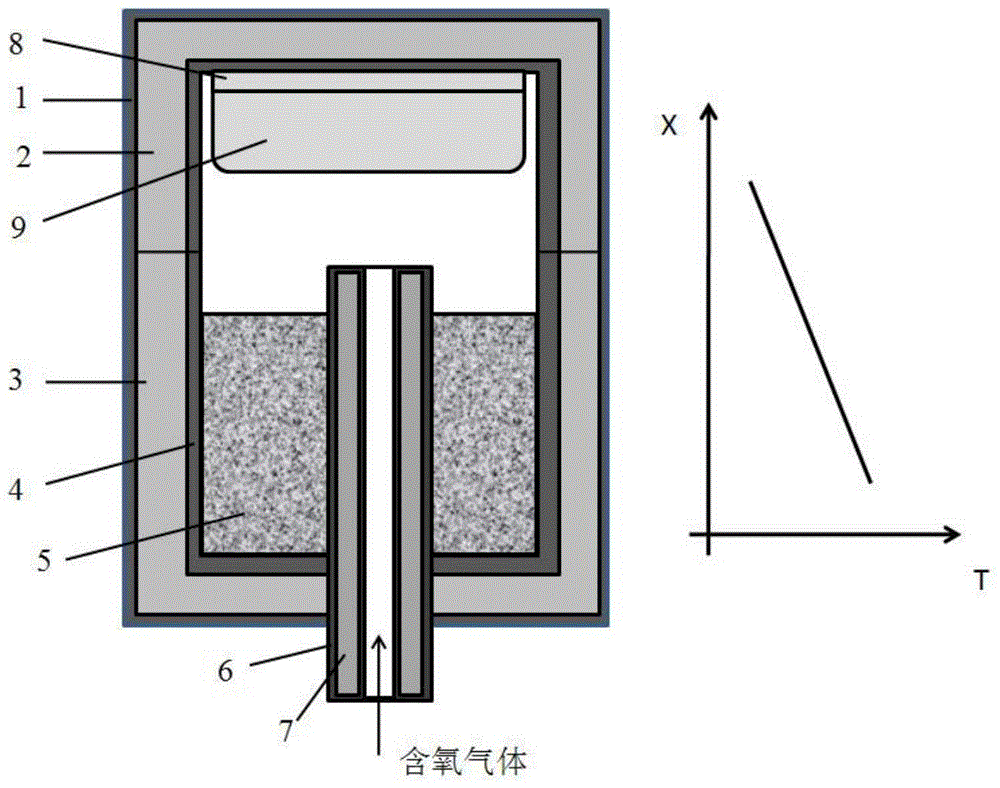

[0039] One piece of 6H-SiC seed crystal with a diameter of 76.2mm, and the Si surface is selected as the crystal growth surface. The schematic diagram of the growth chamber structure is shown in image 3 As shown, the inner and outer sides of the graphite crucible and the inner and outer sides of the graphite pipe are coated with TaC coating. Put the above-mentioned SiC raw material, SiC seed crystal, and the crucible with graphite pipe into the growth furnace, set the temperature at the raw material at 2300-2400°C, and set the temperature at the seed crystal at 100°C lower than the raw material. During the growth process, high-purity argon gas is passed through the growth chamber, with a flow rate of 100 sccm; high-purity carbon dioxide gas is passed into the growth crucible through graphite pipes, and the gas flow rate of carbon dioxide increases linearly with the growth time during the growth process. At the end of the growth, it increased to 15 sccm, and one 6H-SiC crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com