Low-vibration vortex pump volute

A swirl pump, low-vibration technology, applied in pumps, components of pumping devices for elastic fluids, pump elements, etc., to achieve uniform pressure distribution, reduce energy loss, and reduce velocity gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

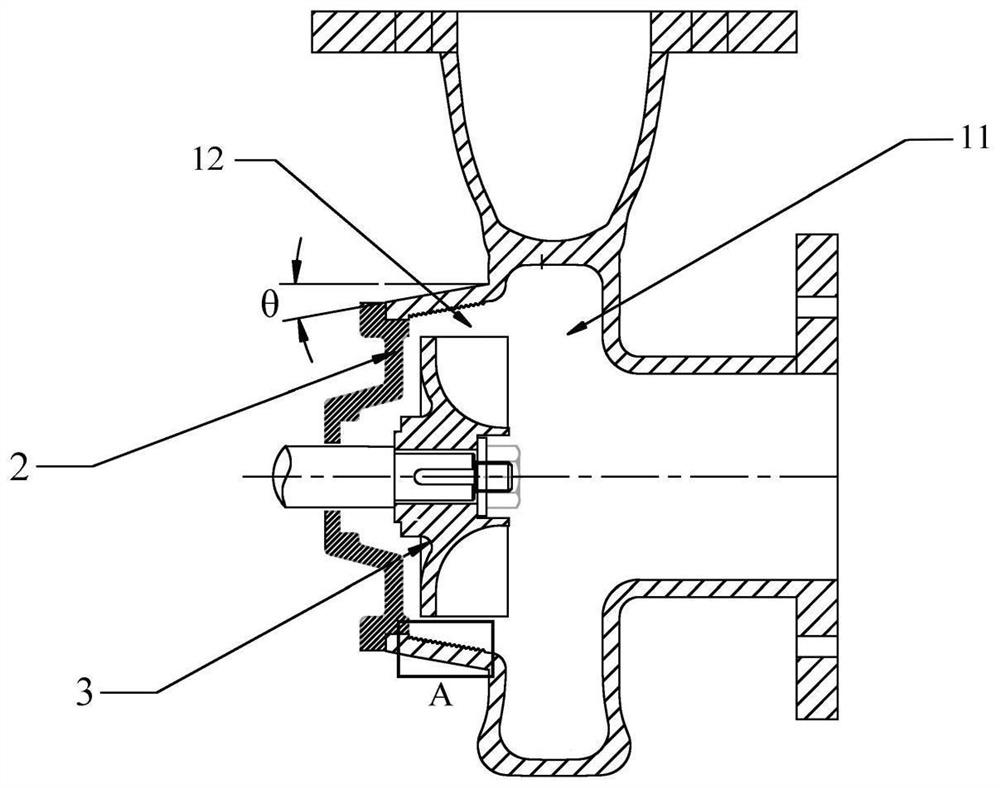

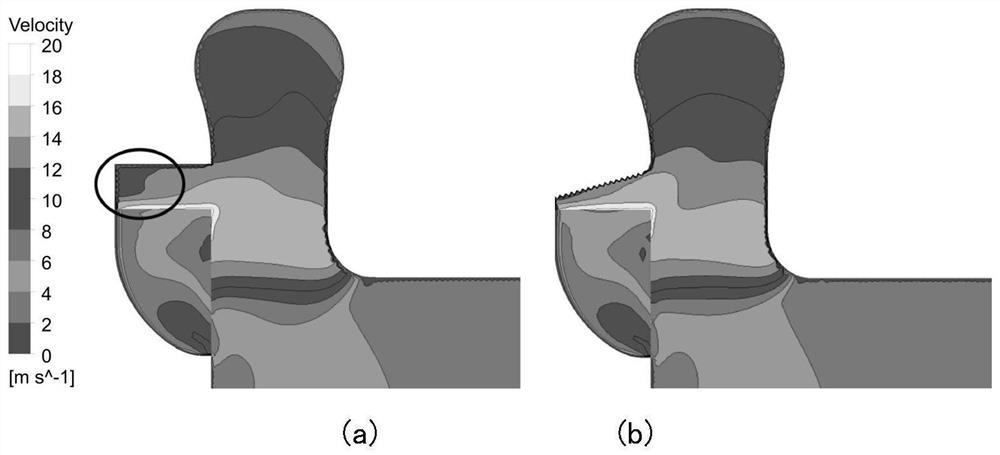

[0026] like figure 1 A schematic structural diagram of the low-vibration swirl pump volute provided by the present invention is illustrated.

[0027] exist figure 1 , the frontal section of the structure of the low-vibration swirl pump volute is provided, and the swirl pump volute may include: a front pump body 11 and a retraction cavity 12 , the front pump body 11 and the retraction cavity 12 are integrated structure; a groove is provided on the inner wall surface of the retraction cavity 12, and the wall surface of the retraction cavity 12 has an inclination angle θ compared to the axis of the volute of the swirl pump;

[0028] The front pump body 11 is used to reduce the speed of liquid flow, so that the speed corresponding to the speed can be converted into pressure energy;

[0029] The setback cavity 12 is used for placing the impeller 3 , increasing the axial distance between the impeller 3 and the inlet of the setback cavity 12 .

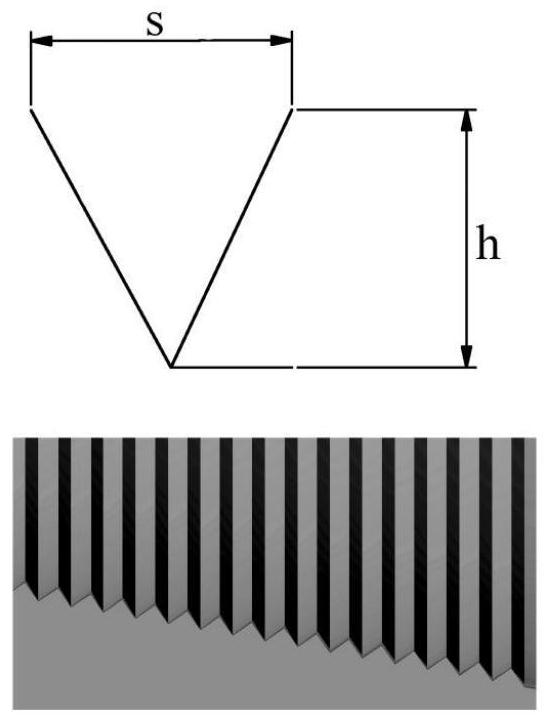

[0030] Optionally, V-shaped grooves...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap