Leakage warning type hydraulic control system

A hydraulic control system, hydraulic technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation system testing, pipeline system, etc., can solve the problem of reducing the maintenance effect of hydraulic control system, increasing the risk of hydraulic control system, pipe joints Surface deformation and other problems can be improved to improve self-inspection effect, improve visibility and reduce hydraulic oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

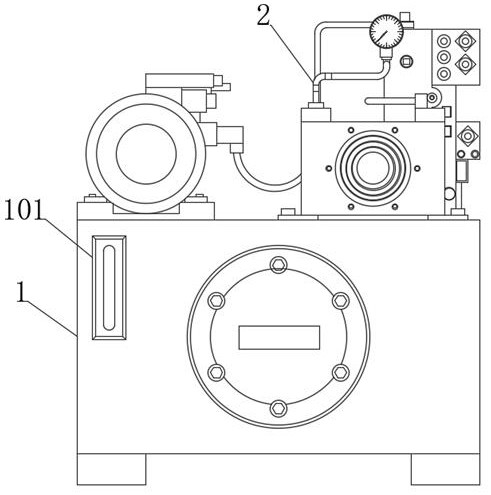

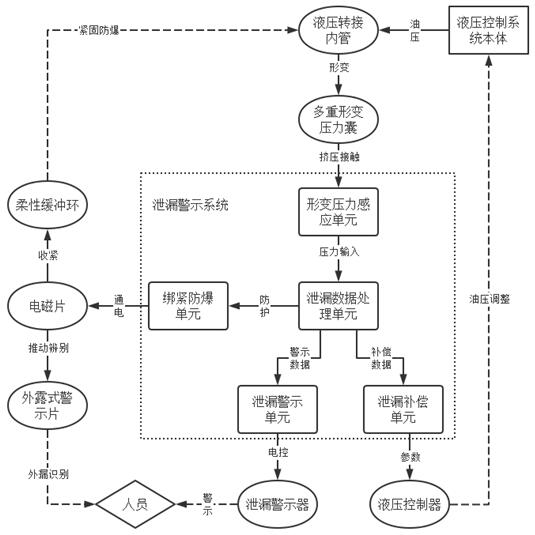

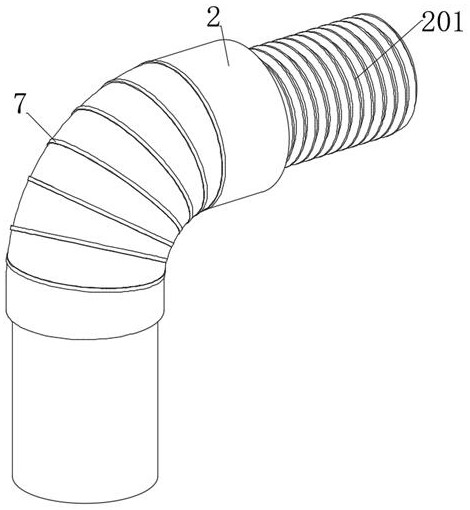

[0047] see Figure 1-11 , a leakage warning hydraulic control system, including a hydraulic control system body 1, a plurality of self-induction pipe joints are installed on the hydraulic control system body 1, and the self-induction pipe joints include a hydraulic adapter inner pipe 201, and the hydraulic adapter The inner pipe 201 is connected with the hydraulic pipe of the hydraulic control system body 1 through the adapter thread. The outer end of the hydraulic adapter inner pipe 201 is fixedly connected with the warning type adapter outer pipe 2, and the warning type adapter outer pipe 2 is provided with a pressure sensing cavity. 202, a barrier shield 3 is fixedly connected to the inner wall of the pressure sensing chamber 202 away from the hydraulic adapter inner pipe 201, and a flexible barrier sheet 301 is fixedly connected to one end of the barrier shield 3 close to the hydraulic adapter inner pipe 201, and the flexible barrier sheet 301 is provided with There are a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com