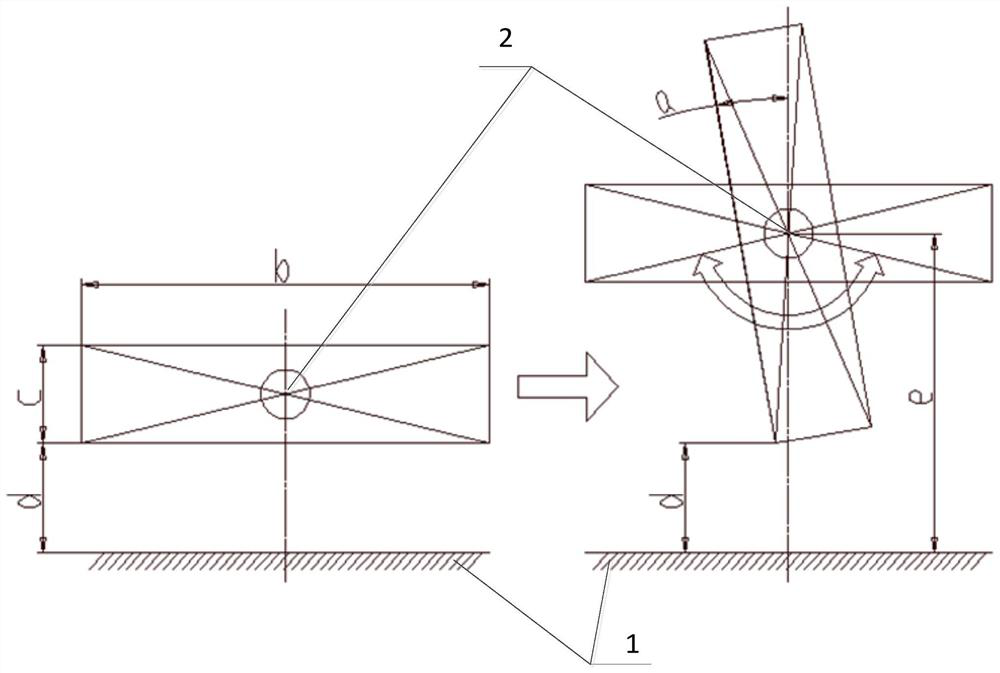

Ultra-wide flat plate unit electro-hydraulic hybrid full-angle pitching mechanism and method

A technology of electro-hydraulic mixing and pitching mechanism, which is applied in the field of transmission mechanism, can solve the problems of limited height and space, and achieve the effect of improving reliability, fewer driving components, and stable theoretical center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

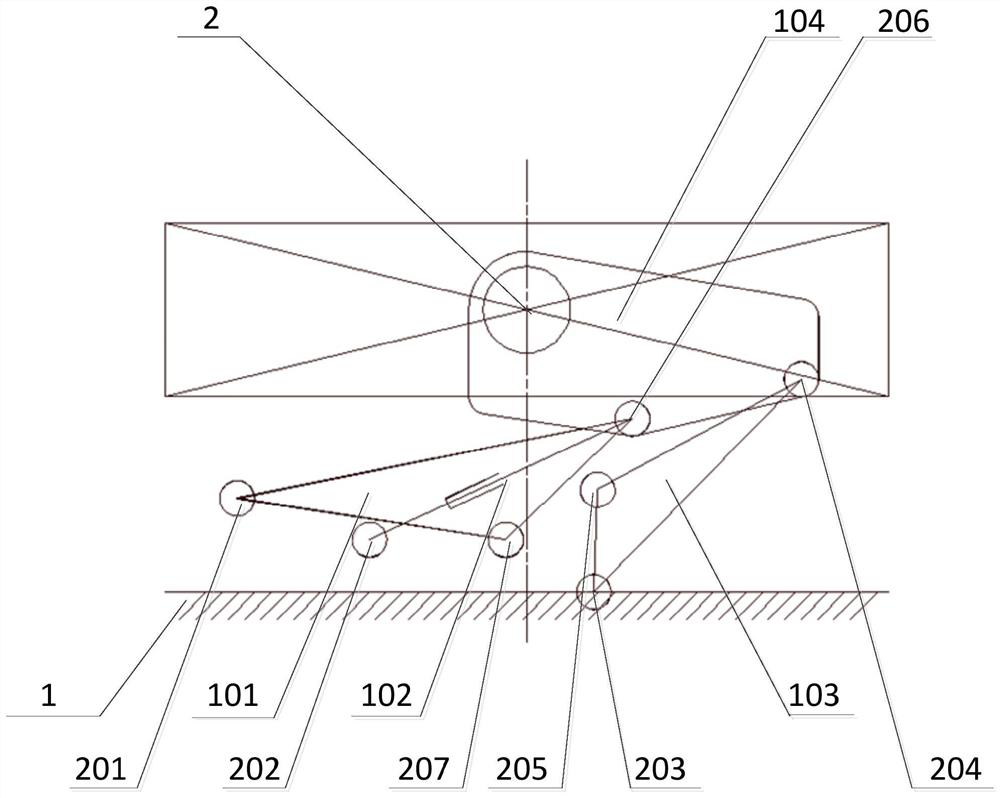

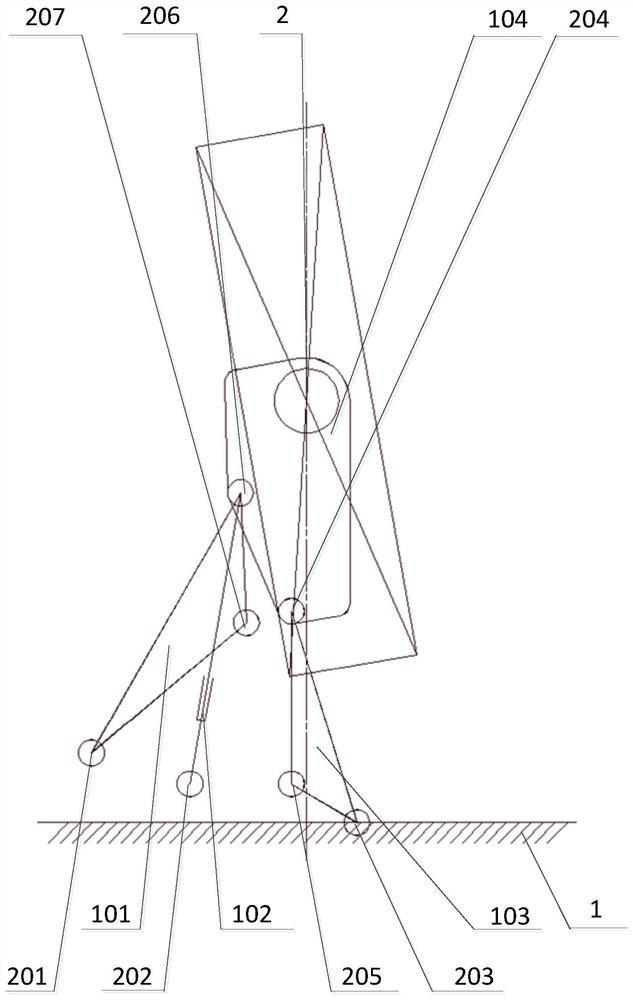

[0050] Embodiment 1: An electro-hydraulic hybrid full-angle pitching mechanism for an ultra-wide flat panel unit, comprising a passive rod 101 , a hydraulic cylinder 102 , an active rod 103 and a component rod 104 connected in sequence.

Embodiment 2

[0051] Embodiment 2: On the basis of Embodiment 1, the passive rod 101 is composed of a triangular area formed by a first node 201 , a sixth node 206 and a seventh node 207 .

Embodiment 3

[0052] Embodiment 3: On the basis of Embodiment 1, the active rod 103 is composed of a triangular area formed by connecting the third node 203 , the fourth node 204 and the fifth node 205 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com