Acoustic radiation plate of dual-frequency ultrasonic radiator

A radiator sound and dual-frequency ultrasonic technology, which is applied in the direction of ultrasonic therapy, treatment, massage auxiliary products, etc., can solve the problems that the dual-frequency ultrasonic radiator acoustic radiating board has not been found in literature reports and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

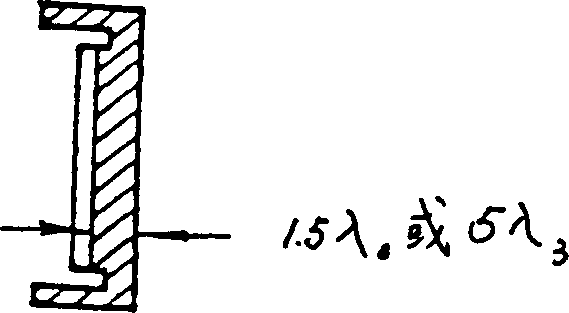

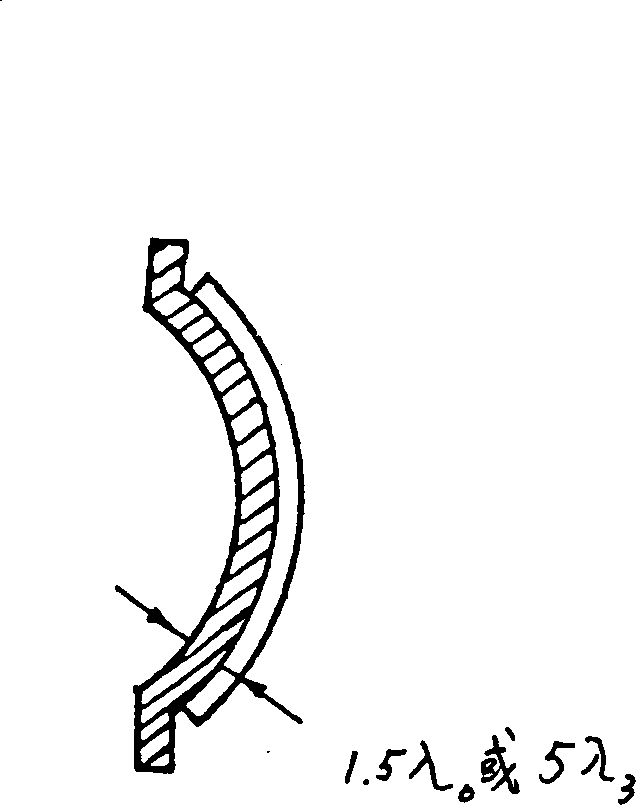

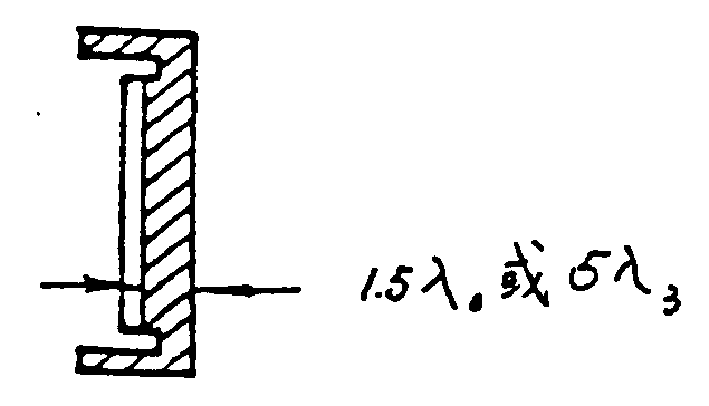

[0012] Such as figure 1 , figure 2 As shown, the plate-shaped non-focused or bowl-shaped focused piezoelectric ceramic transducer vibrator has multiple resonant frequencies (fundamental frequency f 0 and overtone frequency f 3 , f 5 , f 7 ,...) characteristics that allow it to work at the fundamental frequency f 0 and the first overtone frequency f 3 , to calculate the half-wavelength λ of the acoustic radiating panel material at these two frequencies 0 / 2 and λ 3 The least common multiple of / 2, as the thickness of the acoustic radiation plate of the transducer, the thickness of the acoustic radiation plate is equal to 1.5 times the wavelength of the fundamental frequency or 5 times the wavelength of the first overtone frequency, which can meet the dual-frequency working conditions and realize high-power The purpose of high-power dual-frequency ultrasonic emission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com