Method and device for cleaning filter

A filter and cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, filter regeneration, etc., can solve the problem of insufficient cleaning efficiency, lightly polluted filter time loss, difficulty in cleaning filter media, etc. problem, to achieve the effect of improving efficiency and preventing wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

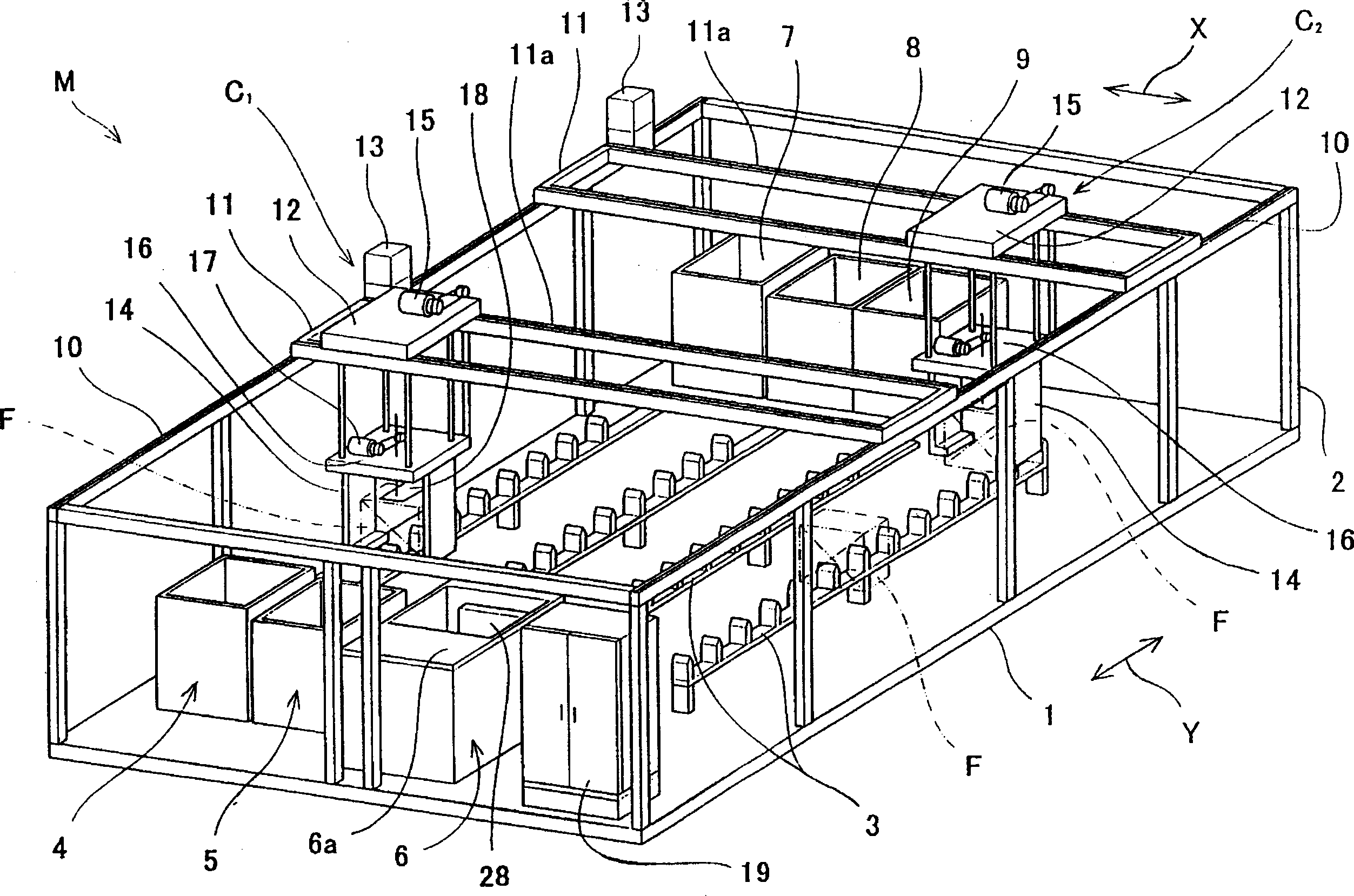

[0033] Such as figure 1 As shown, a support frame 2 of the conveyor units C1 and C2 is provided on a rectangular planar base 1 . Conveyor units C1 and C2 movable in the X and Y directions are installed on the top surface of the support frame 2 . A plurality of guide rails 3 are provided on the base 1 to temporarily accommodate a plurality of filters to be cleaned and cleaned filters. These guide rails 3 are arranged in a plurality of rows in the width direction (X direction) to accommodate a plurality of filters F in the longitudinal direction (Y direction), and each accommodation position is numbered in advance.

[0034] The transportation of the filters to the guide rail 3 is accomplished by a transportation device (not shown) such as a crane or a conveyor belt. The transport unit is equipped with a device for analyzing the degree of contamination of the filter medium (filter insert) to be cleaned. The degree of contamination of the filter medium is determined analytical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com