Sealing device for axial flow turbine

A technology for axial flow turbines and sealing devices, which is applied to the sealing of engines, gas turbine devices, jet propulsion devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

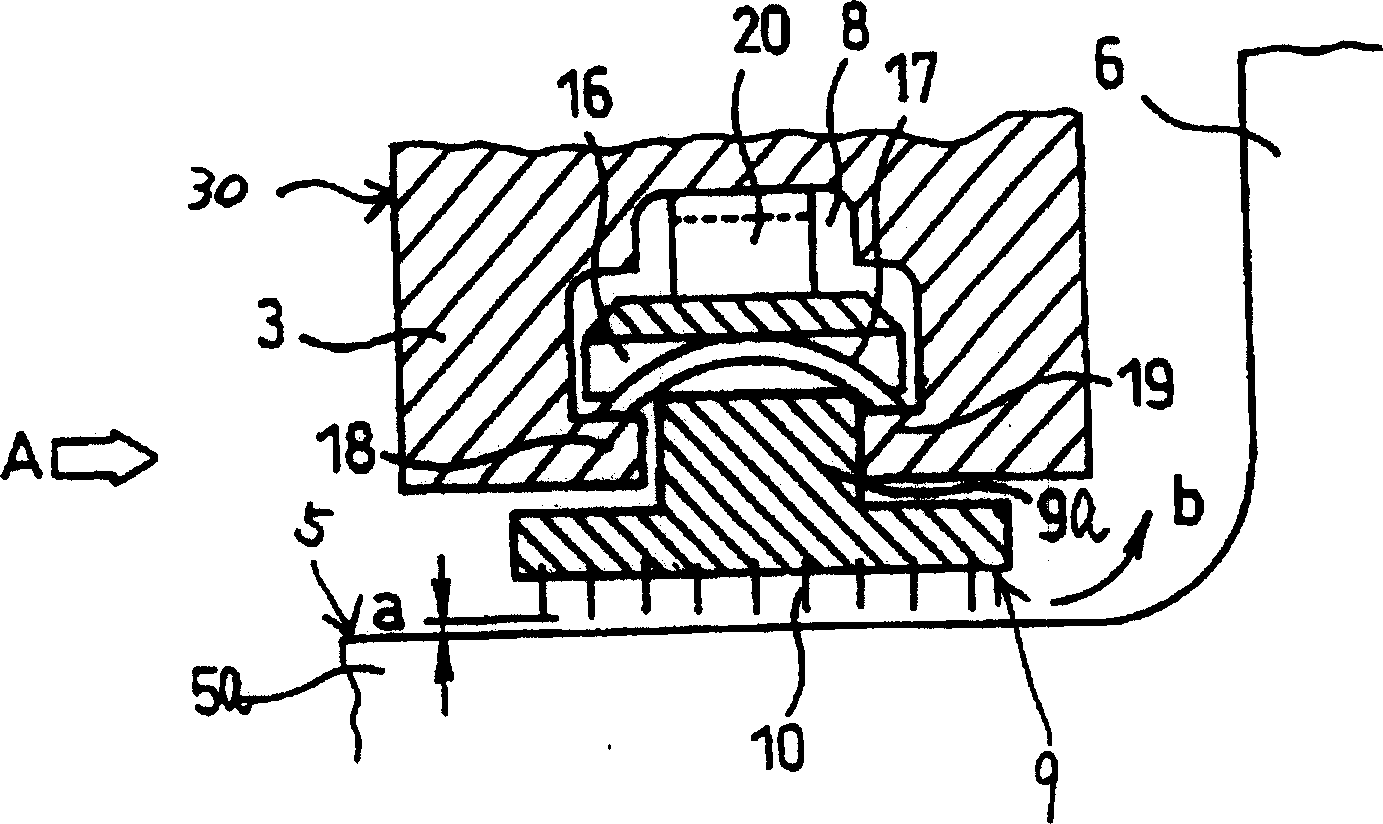

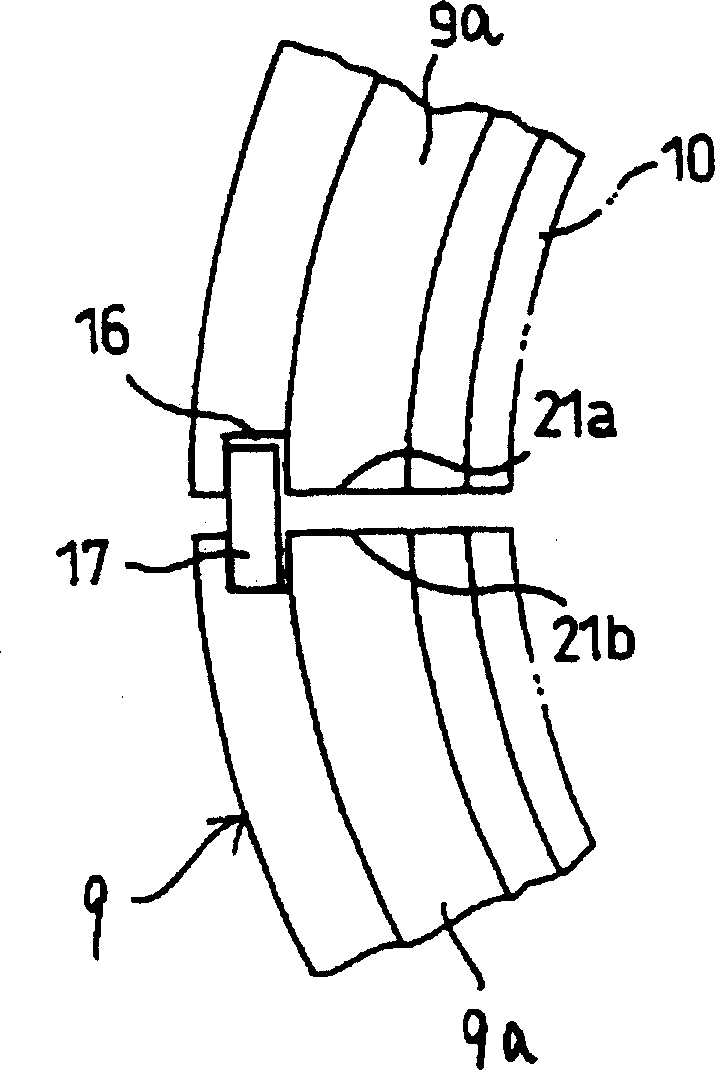

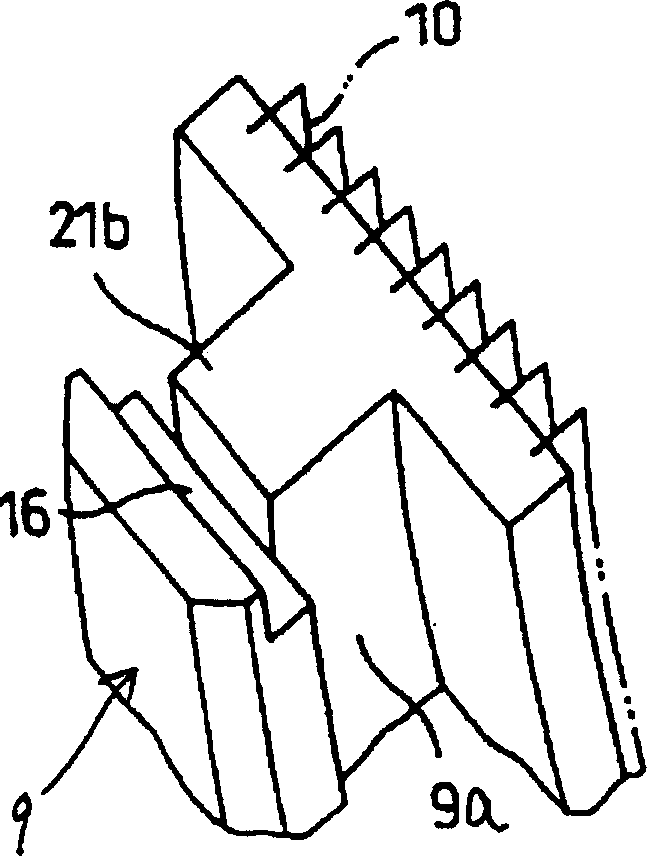

[0052] Next, a sealing device according to a first embodiment of the present invention will be described. The same components as those in the prior art are denoted by the same reference numerals and their descriptions can be omitted. From Figure 1A It can be seen that there is a placement groove 8 on the inner peripheral surface of an inner ring 3 of a nozzle partition 30 , a plurality of sectors 9 a of a sealing ring 9 are distributed along the circumference, and its outer wall is placed in the placement groove 8 . The sealing fins 10 are fixedly installed on the inner surface of the sector body 9a facing the rotor 5 of the axial flow turbine. A gap a is formed between the circumferential surface of the rotor 5 and the sealing fin 10 . The working fluid leaks from the gap a as indicated by the arrow b. Each sector 9a of the sealing ring 9 has an axial through groove 16, and an arc-shaped leaf spring 17 is inserted into the axial through groove 16. Two ends of the arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com