Battery diaphragm and battery using same

A technology for battery separators and composite fibers, which is applied in the direction of nickel storage batteries, alkaline storage batteries, battery pack components, etc., and can solve problems such as poor craftsmanship, ineffective hydrophilic treatment, and low strength of non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

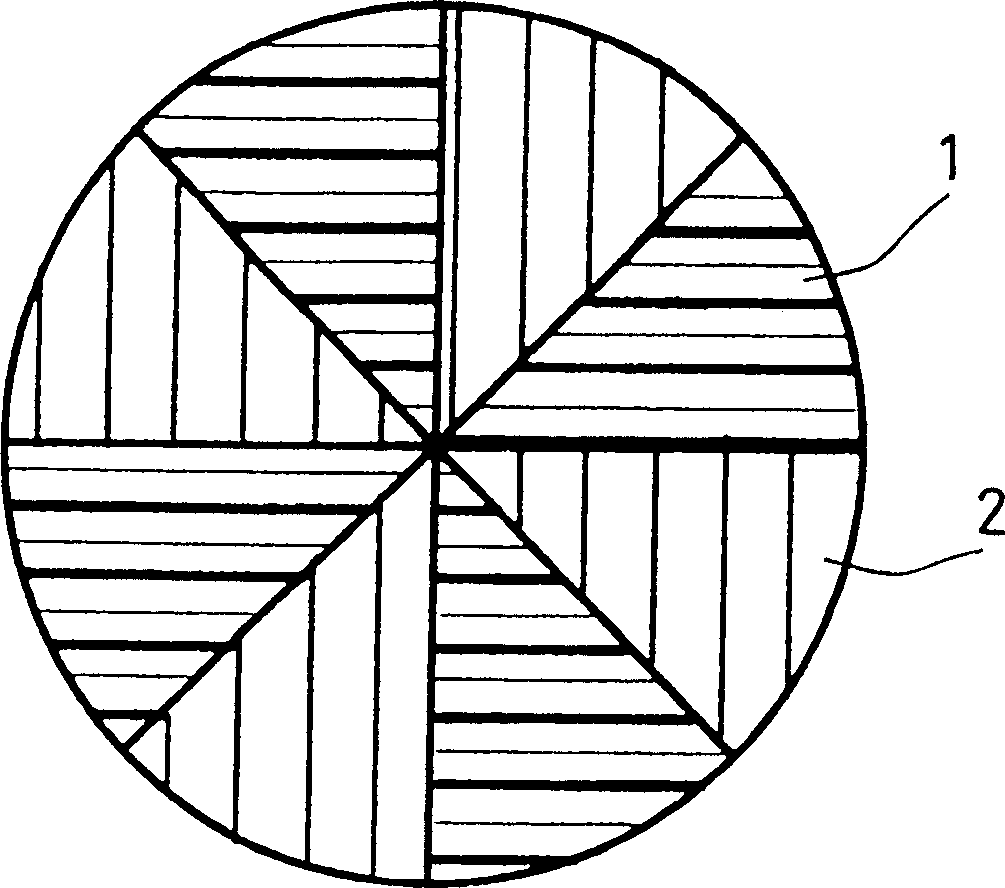

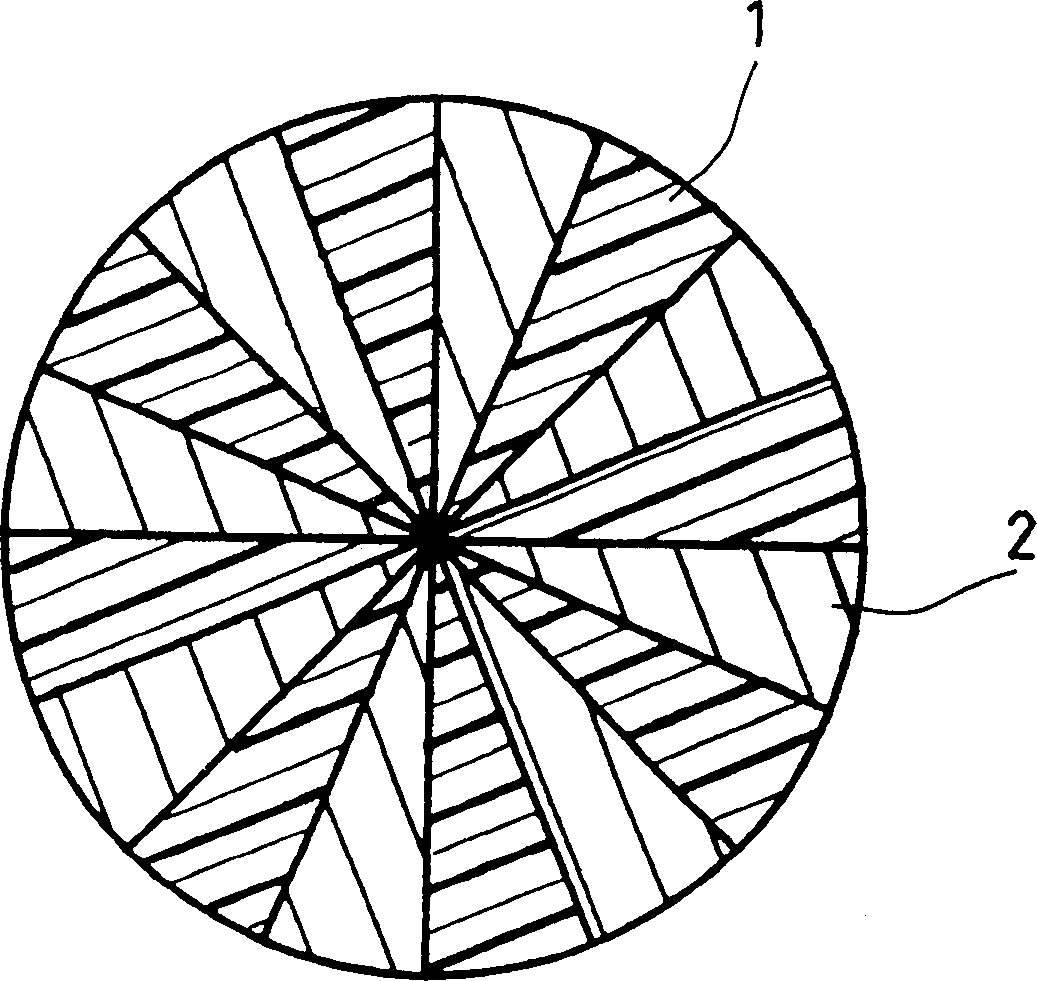

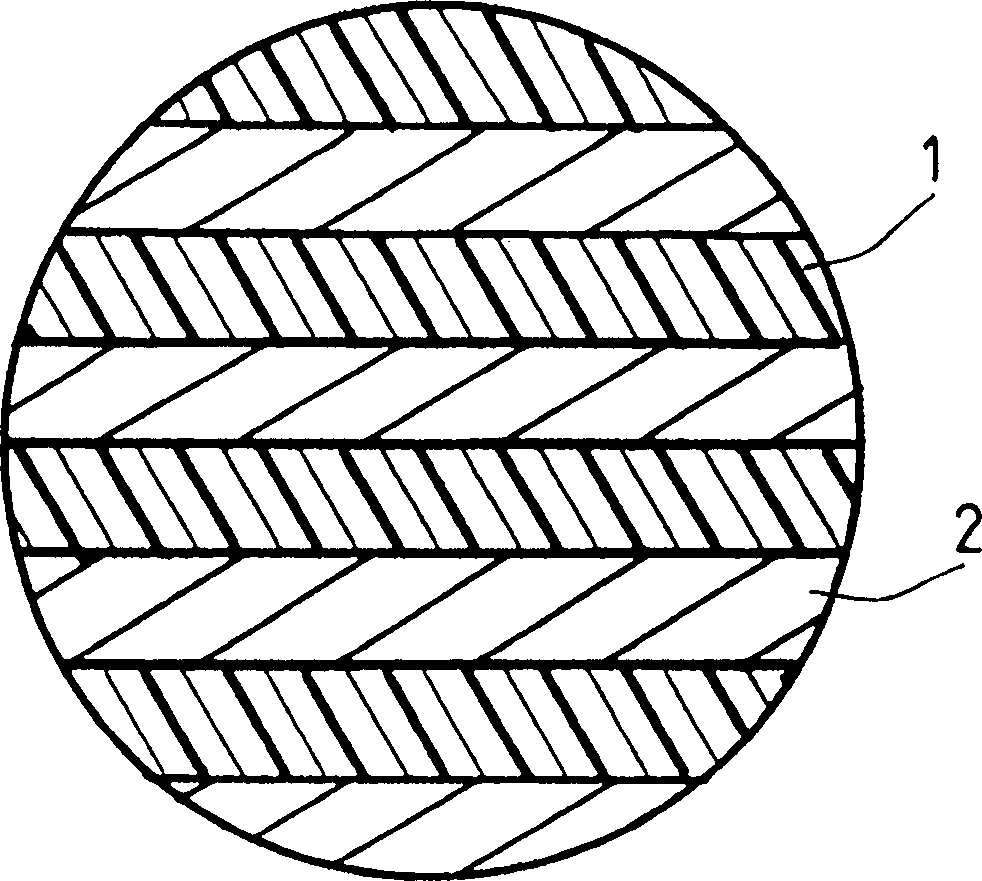

Image

Examples

Embodiment 1

[0071] Mix 40wt% of fiber 1, 40wt% of fiber 3 and 20wt% of fiber 6 to prepare 0.5wt% pulp, and obtain 80g / m by wet papermaking 2 base paper. Then, from the front and back of the base paper, a high-pressure columnar water flow is sprayed under a pressure of 10 MPa, so that the fibers are divided into ultrafine fibers, and at the same time, the fibers are entangled. While drying at 135° C., thermal fusion bonding was carried out to obtain a nonwoven fabric.

[0072] The obtained nonwoven fabric was dipped in a treatment bath at a liquid temperature of 40° C. mixed with 50 wt % chlorosulfonic acid and 50 wt % concentrated sulfuric acid for 1 hour, then dipped in dilute sulfuric acid for 10 minutes, and then dipped in KOH solution for 1 hour. neutralize. Afterwards, it is washed and dried with water, and processed by a hot calender to obtain a fixed volume weight of 65g / m 2 , a battery separator with a thickness of 0.15mm.

Embodiment 2

[0074] Except that treatment liquid is used 100wt% chlorosulfonic acid, with the method identical with embodiment 1, obtain fixed volume weight order 65g / m 2 , a battery separator with a thickness of 0.15mm.

Embodiment 3

[0076] Except that the mixed solution of 20wt% oleum and 80wt% concentrated sulfuric acid is used for the treatment liquid, the same method as in Example 1 is used to obtain a fixed volume weight of 65g / m 2 , a battery separator with a thickness of 0.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com