High voltage transformer

A high-voltage, transformer technology, applied in transformers, inductors, televisions, etc., can solve problems such as large capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

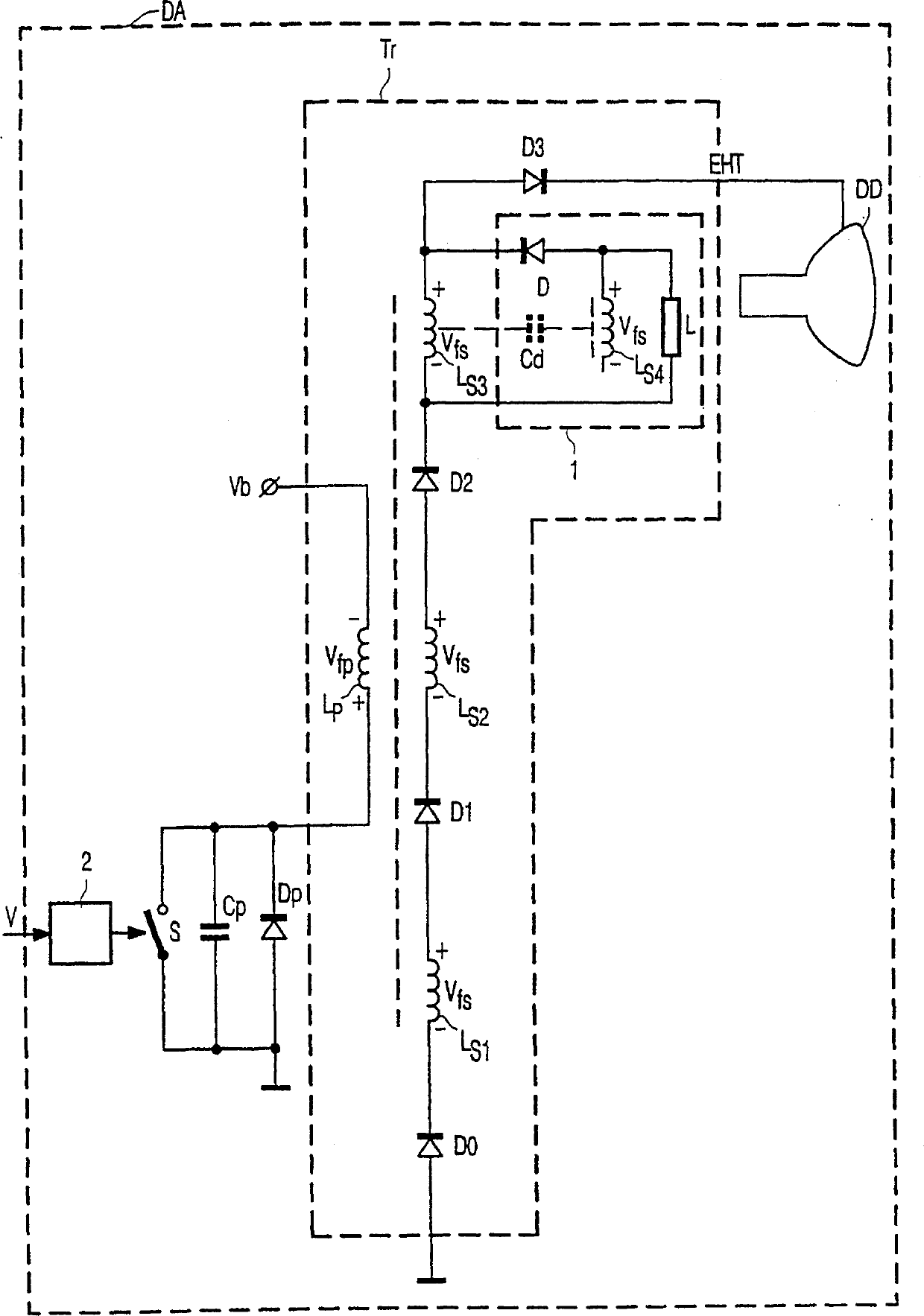

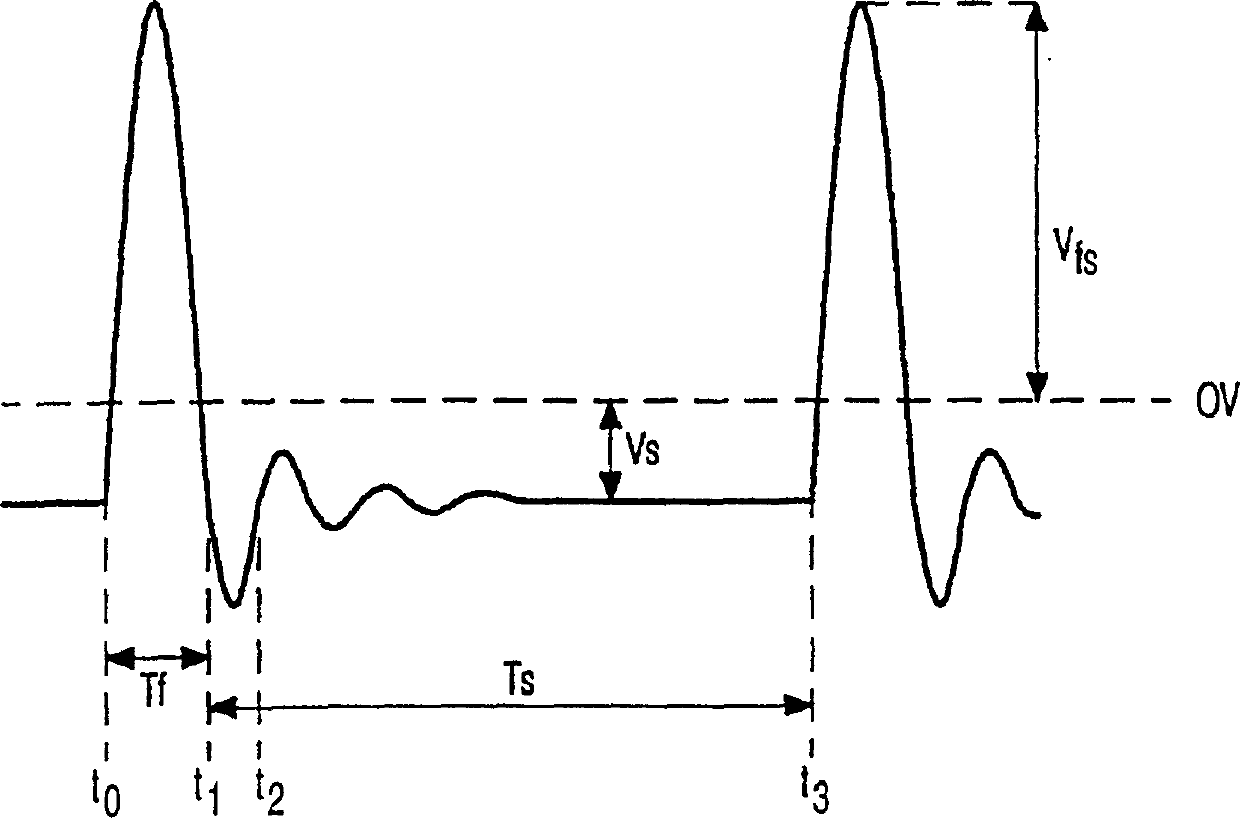

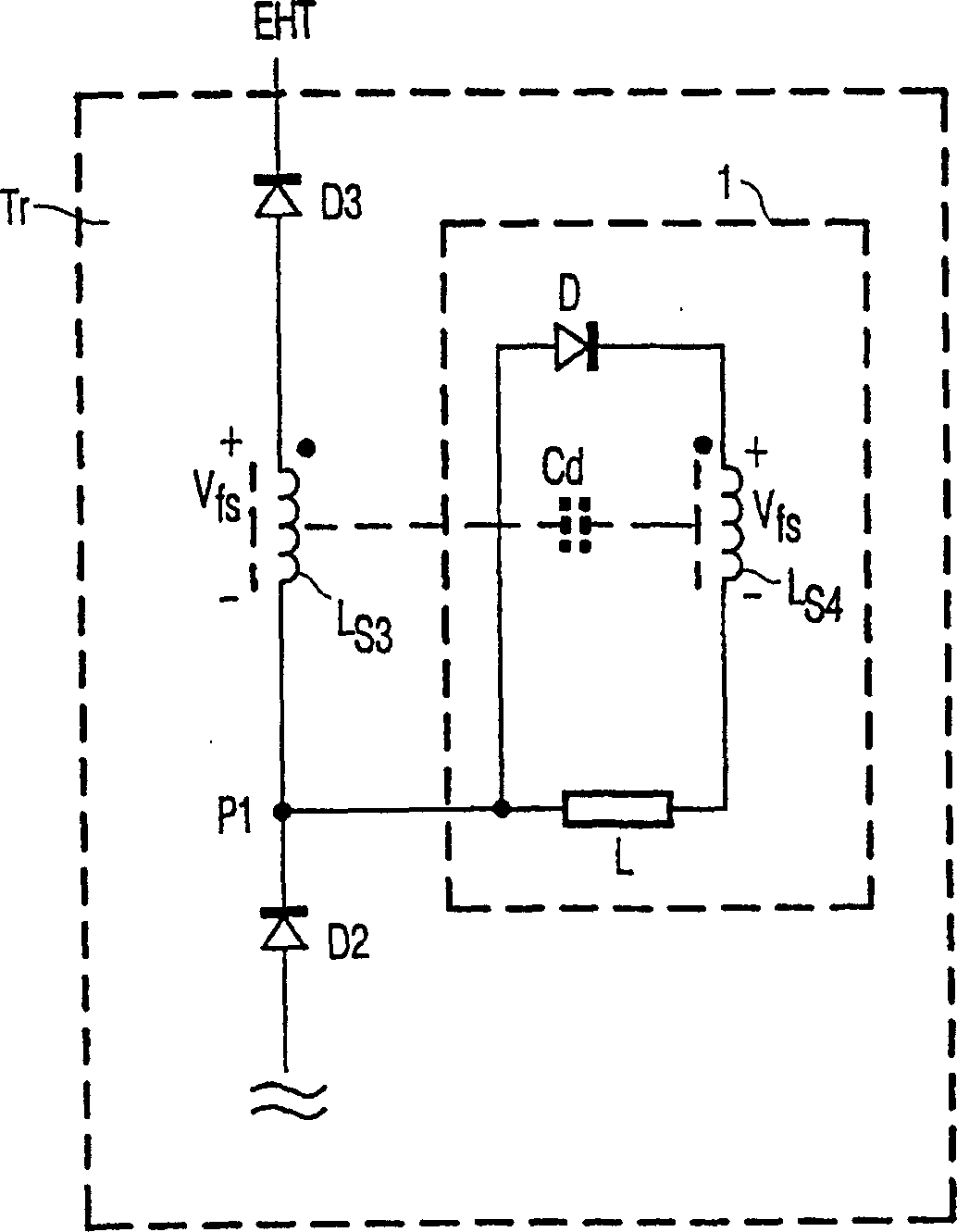

[0013] figure 1 A block diagram of a display device DA comprising a high-voltage transformer Tr with a damping circuit 1 according to a first embodiment of the invention is shown.

[0014] The display device DA includes a control circuit 2, a high voltage transformer Tr, a capacitor Cp, a diode Dp, and a display device DD. This display device can display video signals generated by a television or computer. The primary coil Lp and the switching element S of the high voltage transformer Tr arranged in series receive the power supply voltage Vb. Between ground and the connection point of the primary winding Lp and the switching element S, a capacitor Cp and a diode Dp are connected in parallel. The anode of the diode Dp is connected to the ground. The turn-on and turn-off periods of the switch element S are controlled by the control circuit 2 according to the horizontal synchronization signal separated from the input video signal V. It is also possible to use this line sync s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com