Card wire, especially for doffers and workers

A technology for card clothing and wool needles is applied in the field of improving the efficiency of fiber transfer to small drums and work rolls during textile carding, and can solve problems such as limited application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

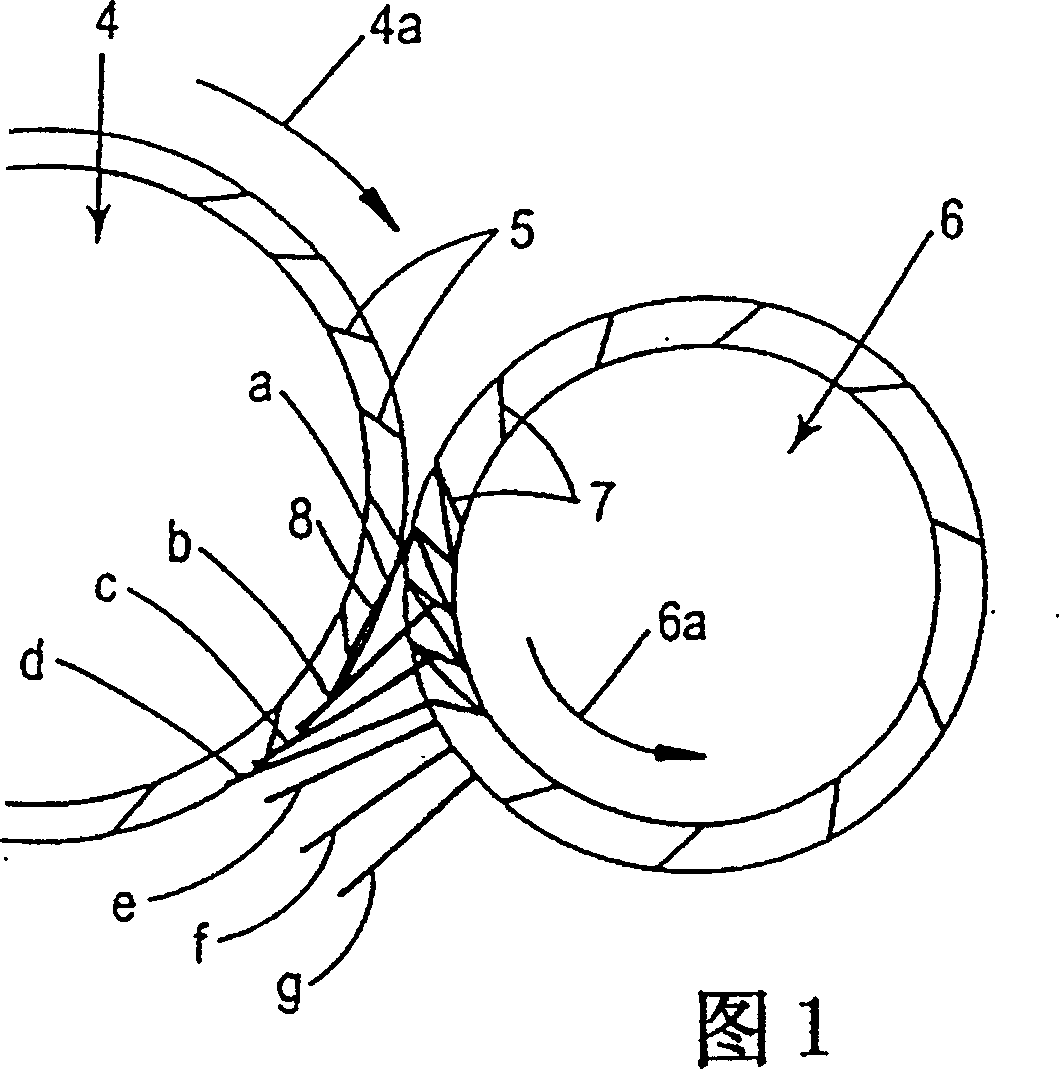

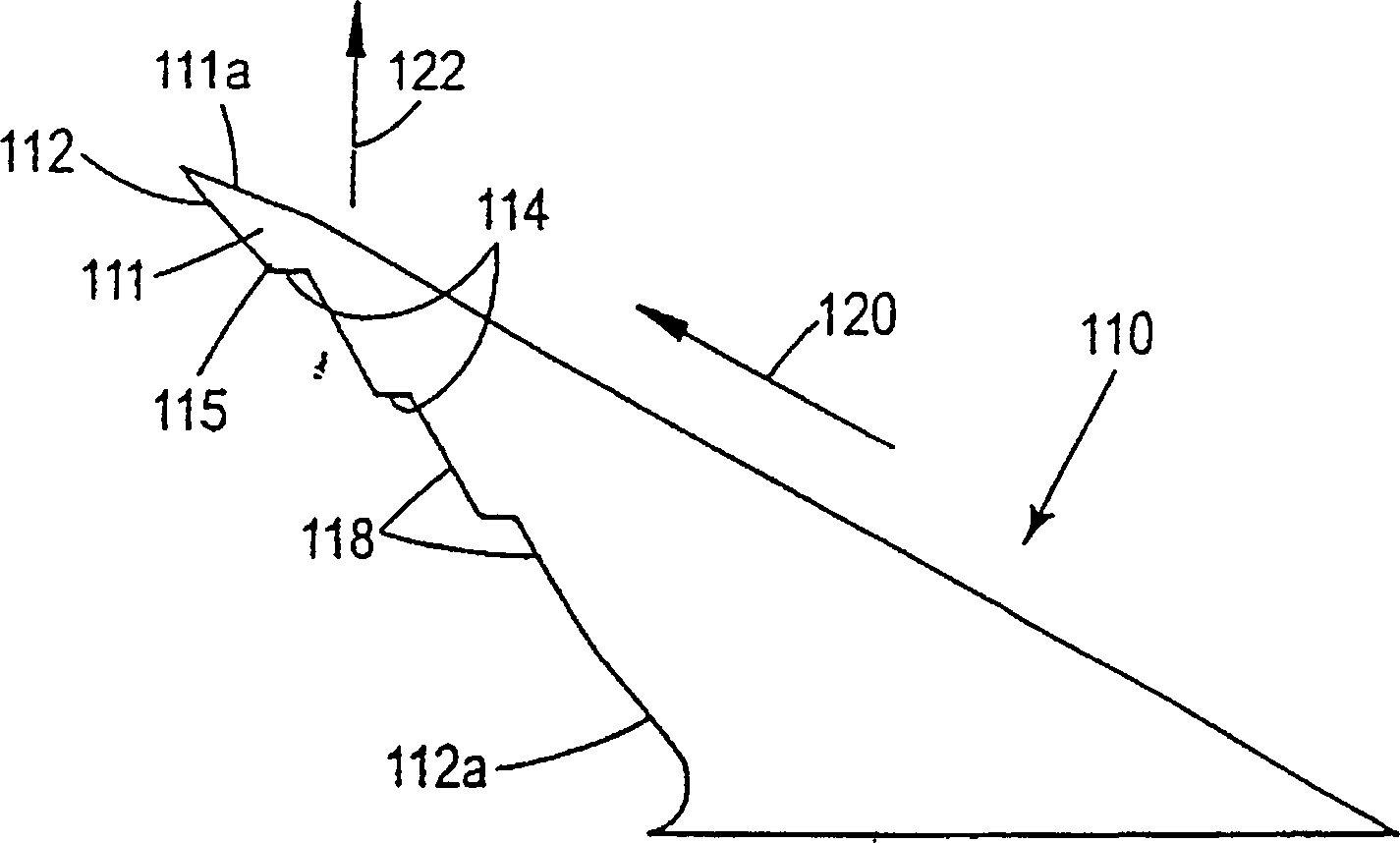

[0024] The teeth of conventional small roller needles have an inboard or beveled returning edge to form an overall overhang shape. The concept of the present invention stems from the realization that the effectiveness of small roller needles can be greatly improved by making the inside or return blade face of the tooth, i.e. the blade face that overhangs below, as parallel as possible to the bottom of the needle . At first glance, this involves making the teeth very slender and very blunt elements, which will improve the gripping of the fibers at all stages of transfer from the large drum to the small drum.

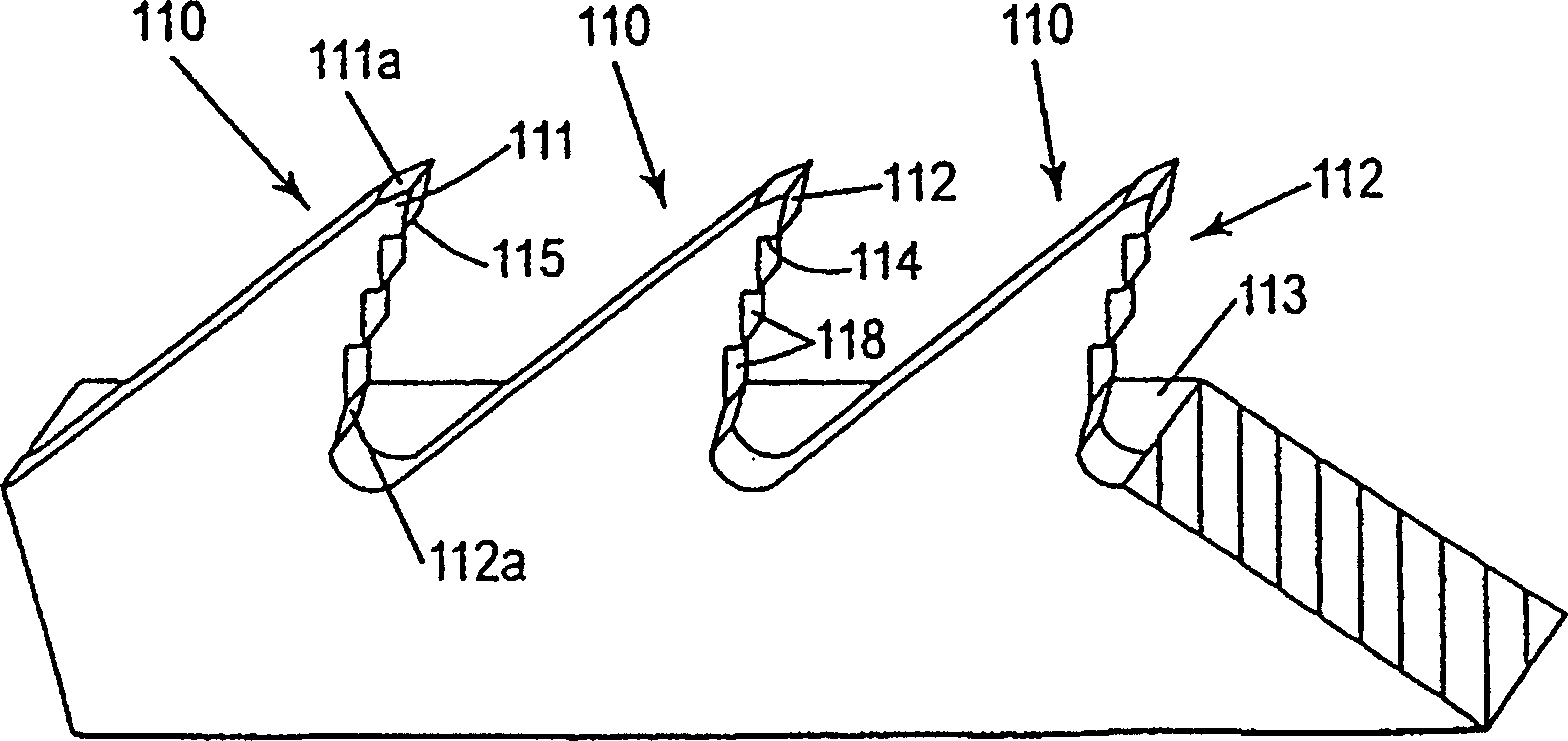

[0025] However, this elongated shape is not the most feasible because, firstly, the teeth may be too thin to be strong enough, and secondly, the space available to accommodate the collected fibers is greatly reduced. The present invention solves this difficulty, but by proposing to form one or more and preferably a plurality of concave cutting edges, preferably parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com