Method for drying pumpkin pulp through combination of ultrasound, freezing and far infrared rays

A technology of far-infrared drying and pumpkin pulp, which is applied in food drying, food ultrasonic treatment, fruit and vegetable preservation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

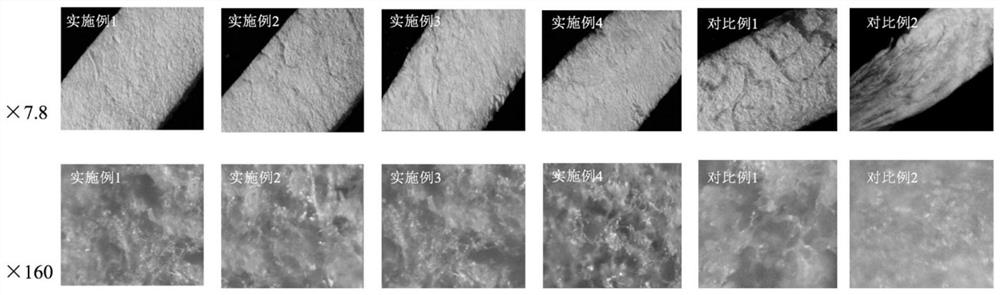

Image

Examples

Embodiment 1

[0040] A method for ultrasonically combined vacuum freezing-far-infrared combined drying of pumpkin pulp for seeds, comprising the following steps:

[0041] (1) Wash the mature, fresh and undamaged seeds with pumpkin, peel and remove the seeds, weigh 200±0.5g of pulp and cut into strips of about 3.5cm×0.8cm×0.3cm;

[0042] (2) Ultrasonic pretreatment: put pumpkin pulp for seeds in step (1) in a beaker filled with 1000 mL of deionized water, immerse an ultrasonic probe with a diameter of 15 mm in distilled water for 15 mm, ultrasonic power 240W, ultrasonic frequency 20KHz, work The temperature is 30°C, and the working time is 30 minutes; after ultrasonic pretreatment, dry the surface moisture of pumpkin pulp for seeds with a paper towel, and place it in a freeze-drying bottle.

[0043] (3) Pre-freezing: place the freeze-dried bottle containing pumpkin pulp for seeds in step (2) in a -30°C refrigerator for 30 hours;

[0044] (4) Vacuum freeze-drying: put the pumpkin pulp for se...

Embodiment 2

[0049] A method for vacuum-far-infrared segmented drying of pumpkin pulp for seeds combined with ultrasound, comprising the following steps:

[0050] (1) is identical with the step (1) in embodiment 1;

[0051] (2) same as step (2) in embodiment 1;

[0052] (3) same as step (3) in embodiment 1;

[0053] (4) The difference from step (4) in Example 1 is that the vacuum freeze-drying until the water content conversion point is 40%. Close the freeze-vacuum dryer, take out the pumpkin pulp for seeds, and put it into a far-infrared drying device to continue drying;

[0054] (5) same as step (5) in embodiment 1;

[0055] (6) is the same as step (6) in Example 1.

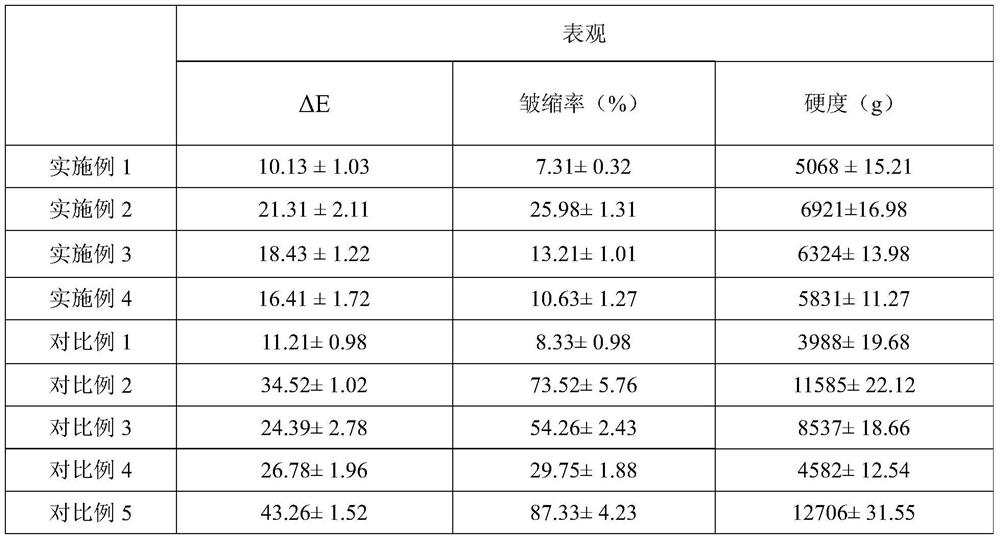

[0056] The invention improves the freeze-drying efficiency of pumpkin for seeds. Compared with freeze-drying alone, the total drying time is shortened by 51.75% by using ultrasonic pretreatment combined with vacuum freezing-far-infrared segmental drying. Compared with separate far-infrared drying, the product The appea...

Embodiment 3

[0058] A method for vacuum-far-infrared segmented drying of pumpkin pulp for seeds combined with ultrasound, comprising the following steps:

[0059] (1) is identical with the step (1) in embodiment 1;

[0060] (2) same as step (2) in embodiment 1;

[0061] (3) same as step (3) in embodiment 1;

[0062] (4) same as step (4) in embodiment 1;

[0063] (5) The difference from step (5) in Example 1 is that the temperature of the far-infrared drying device is set to 80°C. When the temperature in the drying box reaches 80°C and is basically constant, use pumpkin pulp for the seeds in step (4). Put it into it and dry until the moisture content drops to 7% of the final safe moisture content, then stop drying;

[0064] (6) is the same as step (6) in Example 1.

[0065] The invention improves the freeze-drying efficiency of pumpkin for seeds. Compared with freeze-drying alone, the total drying time is shortened by 33.5% by using ultrasonic pretreatment combined with vacuum freezing-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com