Organic-solvent-free ultrasonic extracting method for ginger essential oil

An organic solvent, ultrasonic technology, applied in the direction of essential oil/spice, fat production, etc., can solve the problems of high energy consumption, long distillation time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

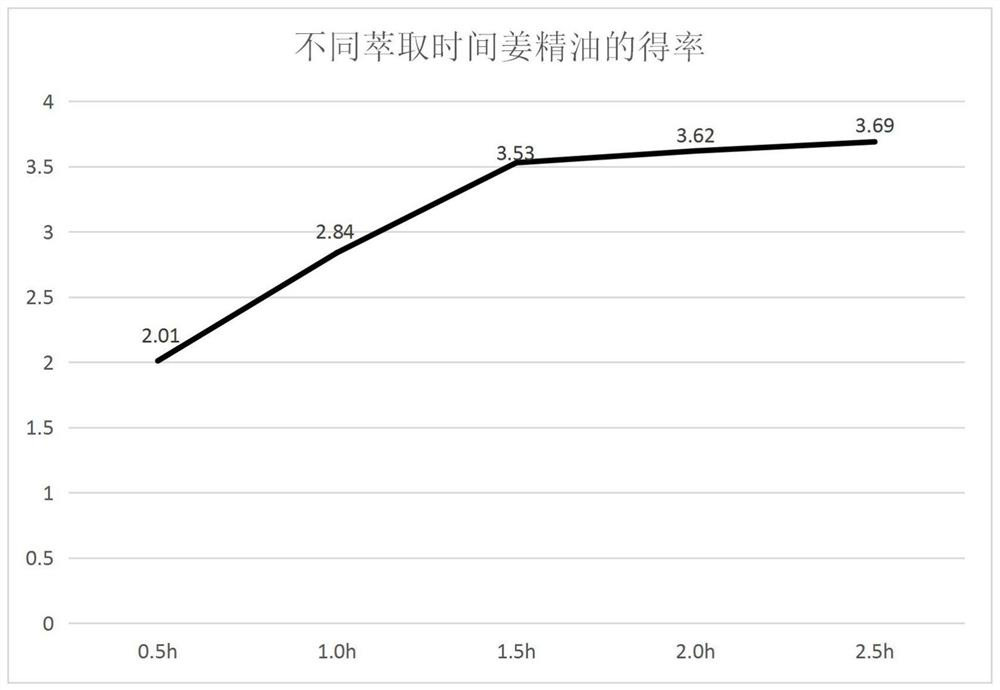

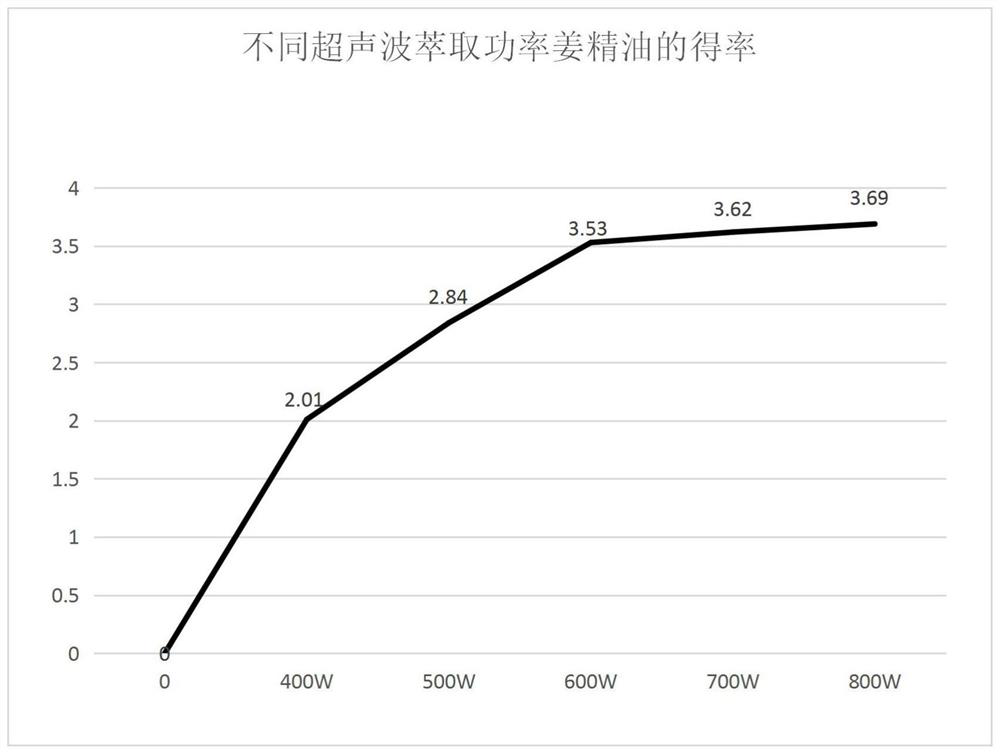

Examples

Embodiment 1

[0061] A method for organic solvent-free ultrasonic extraction of ginger essential oil, the steps are as follows:

[0062] (1) Get 1kg of fresh ginger, squeeze it mechanically, and separate the liquid slag to obtain ginger juice and ginger slag;

[0063] (2) The ginger slag obtained in step (1) is placed in a vacuum low-temperature drying box for processing, and the set temperature is 80° C., kept for 20 minutes, and the temperature for drying by vacuuming is 60° C., and kept for 20 minutes, so that the moisture contained in the ginger is reduced. The mass percentage is lower than 5%, and dried ginger residue is obtained;

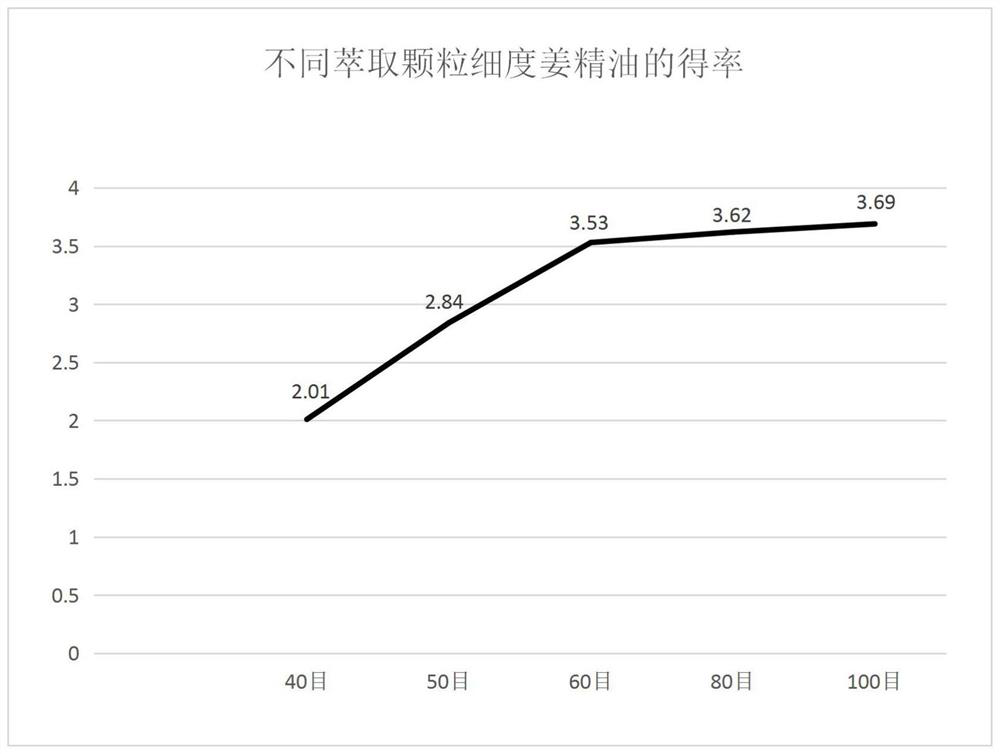

[0064] (3) pulverize the dried ginger slag obtained in step (2) with a pulverizer to 40 orders, and obtain ginger slag powder;

[0065] (4) The ginger slag powder obtained in the step (3) is mixed with water and soaked to obtain a mixed slurry; wherein, the ratio of the quality of the ginger slag powder to the volume of water is 1:5, and it is placed in th...

Embodiment 2

[0070] A method for organic solvent-free ultrasonic extraction of ginger essential oil, the steps are as follows:

[0071] (1) Get 1kg of fresh ginger, squeeze it mechanically, and separate the liquid slag to obtain ginger juice and ginger slag;

[0072] (2) The ginger slag obtained in step (1) is placed in a vacuum low-temperature drying box for processing, and the set temperature is 70° C., kept for 30 minutes, and the temperature for drying by vacuuming is 50° C., and dried for 30 minutes, so that the moisture contained in the ginger is reduced. The mass percentage is lower than 5%, and dried ginger residue is obtained;

[0073] (3) Grinding the dried ginger slag obtained in step (2) with a pulverizer to 50 orders to obtain ginger slag powder;

[0074] (4) The ginger slag powder obtained in the step (3) is mixed with water and soaked to obtain a mixed slurry; wherein, the ratio of the quality of the ginger slag powder to the volume of water is 1:8, and it is placed in the ...

Embodiment 3

[0079] A method for organic solvent-free ultrasonic extraction of ginger essential oil, the steps are as follows:

[0080] (1) Get 1kg of fresh ginger, squeeze it mechanically, and separate the liquid slag to obtain ginger juice and ginger slag;

[0081] (2) The ginger slag obtained in step (1) is placed in a vacuum low-temperature drying box for processing, and the set temperature is 60° C., kept for 40 minutes, and the temperature for drying by vacuuming is 40° C., and kept for 40 minutes, so that the moisture contained in the ginger is reduced. The mass percentage is lower than 5%, and dried ginger residue is obtained;

[0082] (3) Grinding the dried ginger slag obtained in step (2) with a pulverizer to 60 orders to obtain ginger slag powder;

[0083] (4) The ginger slag powder obtained in the step (3) is mixed with water and soaked to obtain a mixed slurry; wherein, the ratio of the quality of the ginger slag powder to the volume of water is 1:10, and it is placed in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com