Load driver

A carrier-driven, carrier-based technology, applied to valve devices, devices to prevent accidental or unauthorized actions, valve operation/release devices, etc., can solve problems such as accidents in load-driven devices, and ensure safety and operation Efficiency improvement and load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

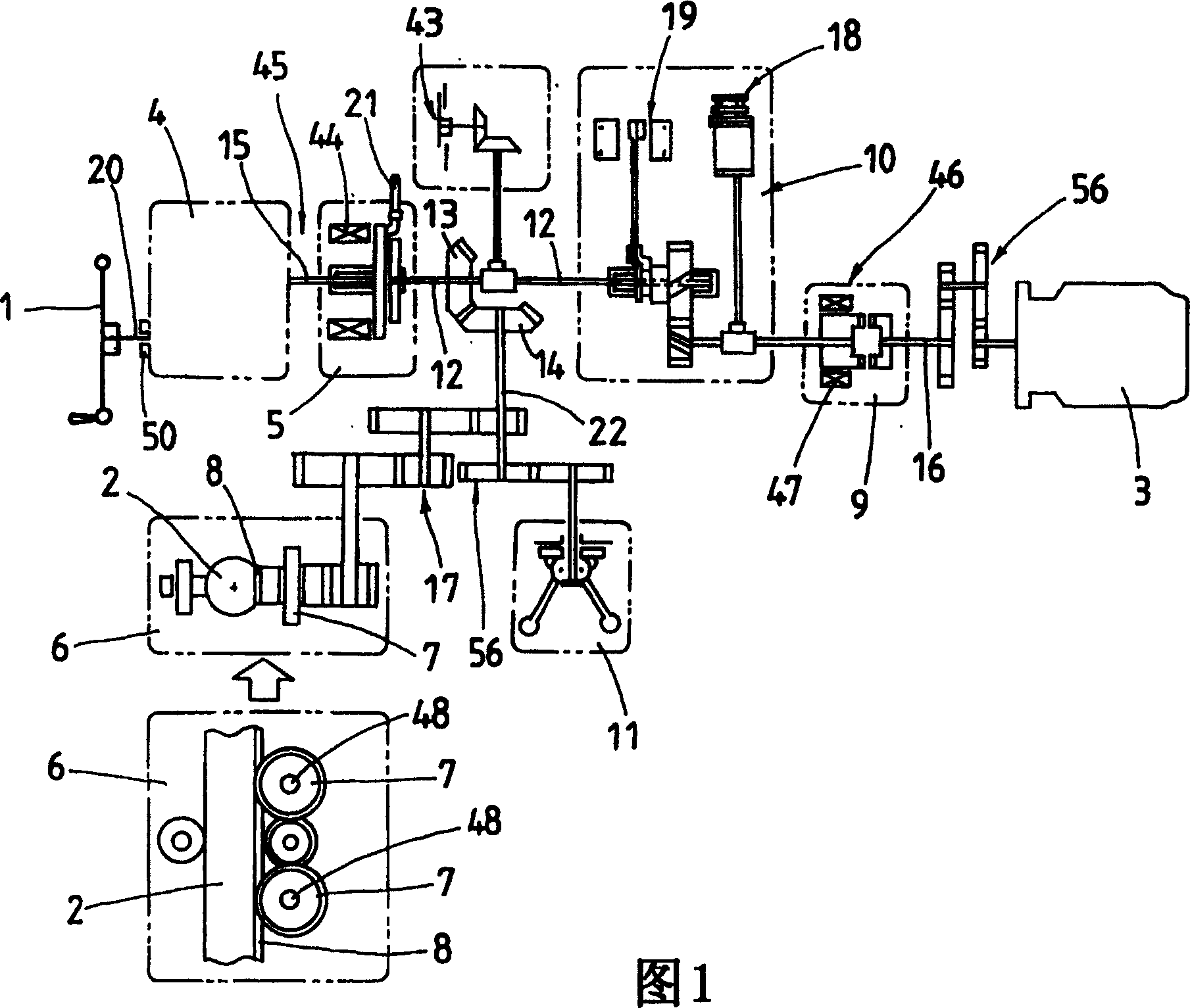

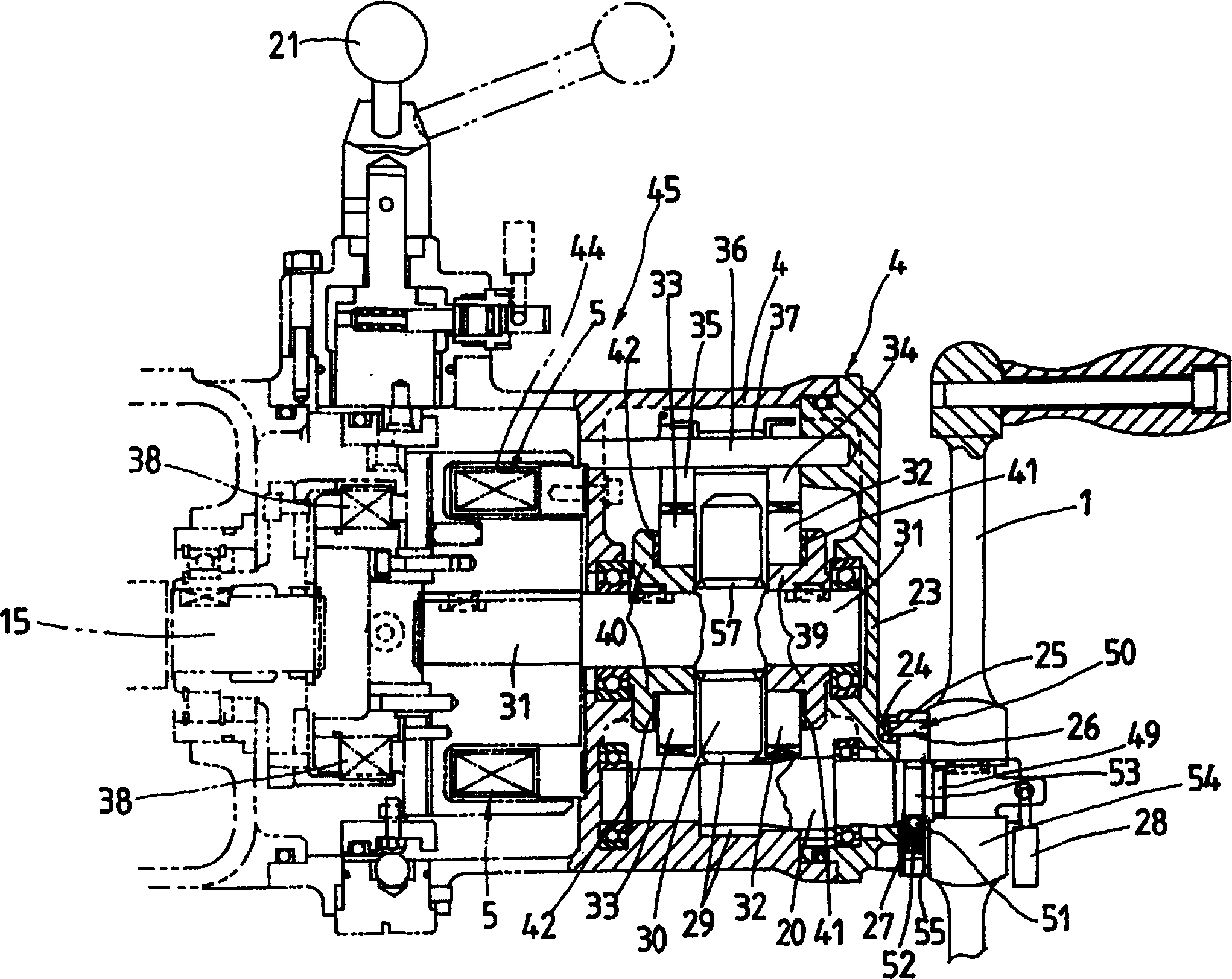

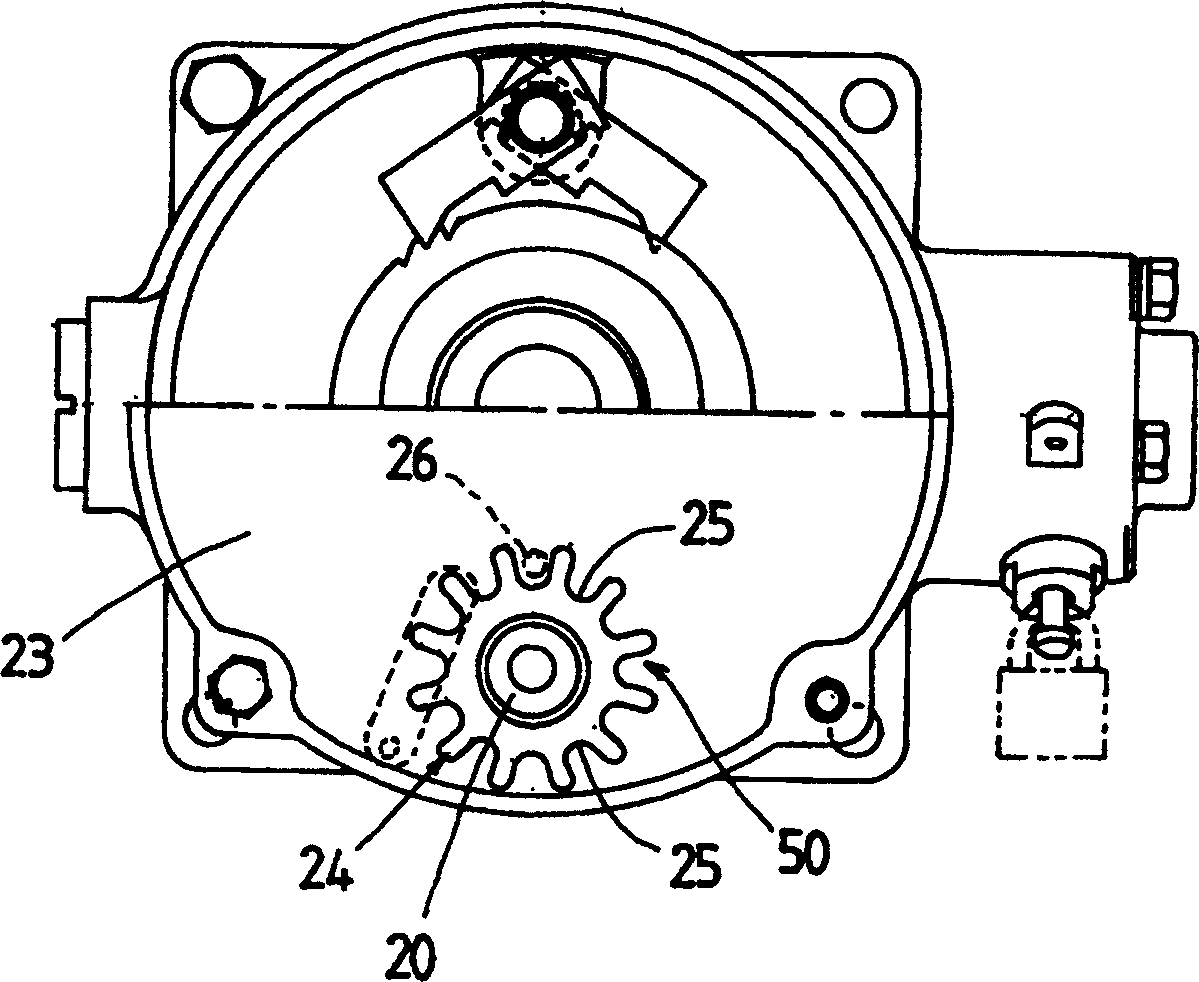

[0025] Embodiments of the load driving device of the present invention will be described below with reference to the accompanying drawings. The load body drive device is provided with: a power transmission device for driving up and down load bodies (not shown) such as weir plates, gates, door bodies, valves, etc. used to control the fluid flow in pipelines such as waterways and tap water; The operation of the handle 1 is interlocked with a manual handle interlock mechanism 50 . The main components of the load drive device are: the main shaft 2 on which the load is mounted; the rack and pinion mechanism 6 for raising and lowering the main shaft 2; the power transmission device 17 having a speed reducer 56 and the like; The 1st clutch 5 that electromagnet 44 and multi-plate disc 38 constitute; The 2nd clutch 9 that is constituted by the electromagnet 47 that is located in the electric drive system 46; Constitute the screw brake 4 of the self-locking mechanism located in the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com