Dual-layer glow ion carbonizing apparatus and process

A double-layer glow ion, carburizing device technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor composition controllability, long processing time, poor controllability, etc. The effect of increasing penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

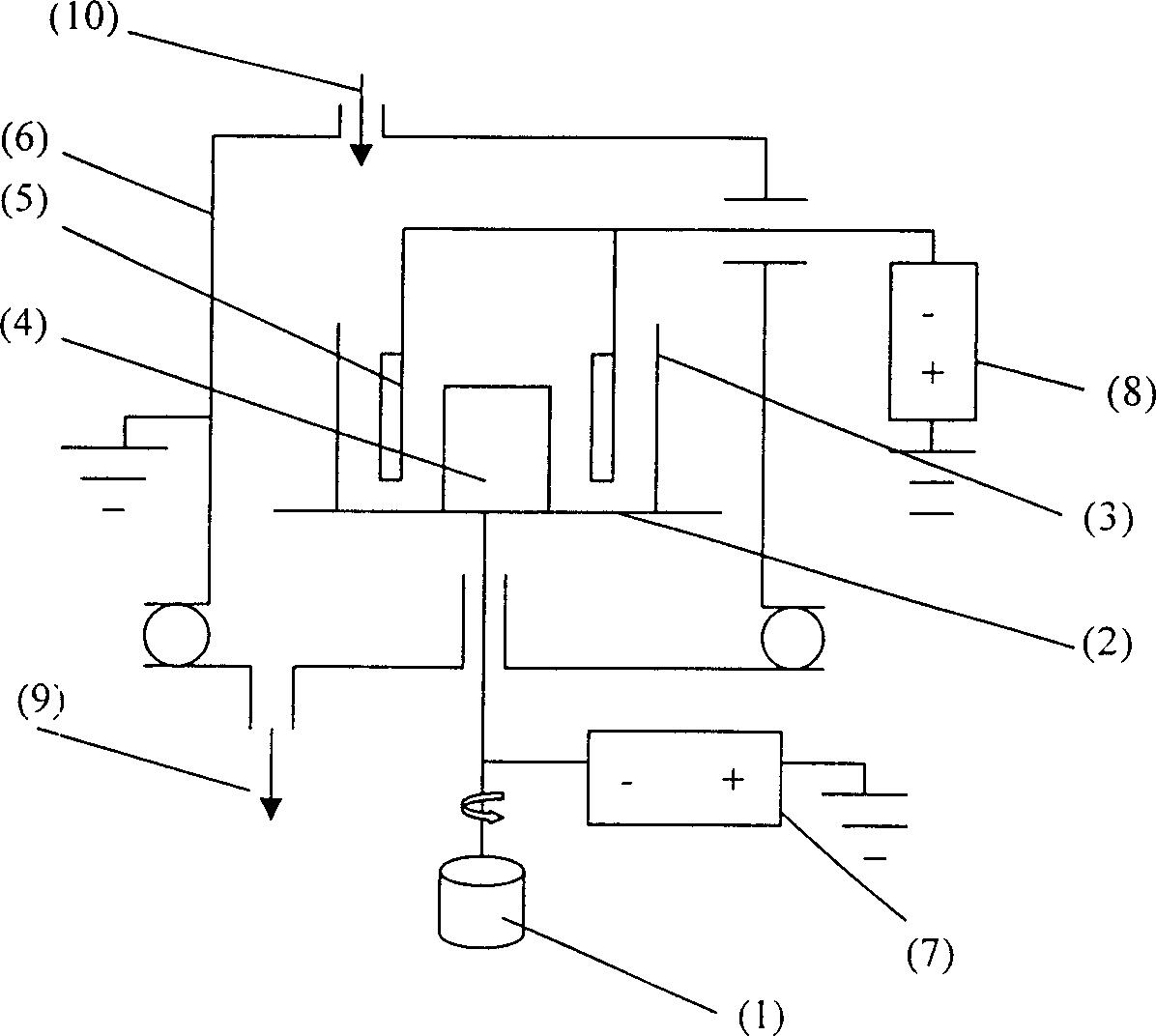

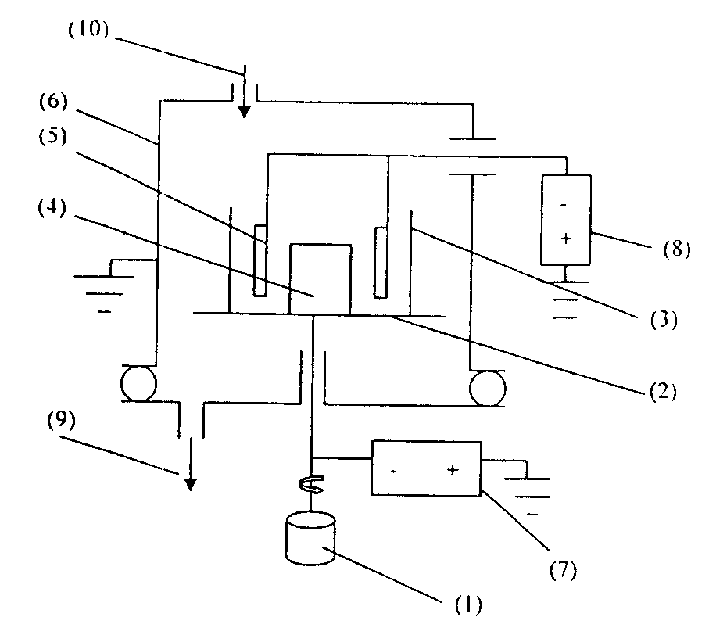

[0017] Embodiments of the present invention are as follows: as shown in the accompanying drawings. Place a size of 40mm×20mm (diameter×high) 20 steel workpieces 4 in a hollow steel auxiliary cathode 3 with a size of 80mm×50mm (diameter×high), and hang the size 25mm×20mm along the circumference in the auxiliary cathode 3 5 graphite strips of ×5mm (length×width×thickness), ensuring that the graphite source strip 5 is in the middle of the distance between the inner diameter of the auxiliary cathode 3 and the outer diameter of the workpiece 4 . Vacuum up to 10 -1 After Pa, fill argon gas to 40Pa, add high-voltage DC heating voltage-500V between the workpiece 4 and the vacuum container 6, and add high-voltage DC sputtering voltage-1000V between the graphite source bar 5 and the vacuum container 6, After the workpiece is heated up to 1000°C, keep it warm for 1.5 hours, cool down to room temperature, and take out the sample. The carburizing result with a surface carburized layer th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com