Universal AC/DC motor

A technology for AC and DC motors and casings, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of easy generation of eddy currents, increased motor temperature, poor mechanical strength of cast iron casings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

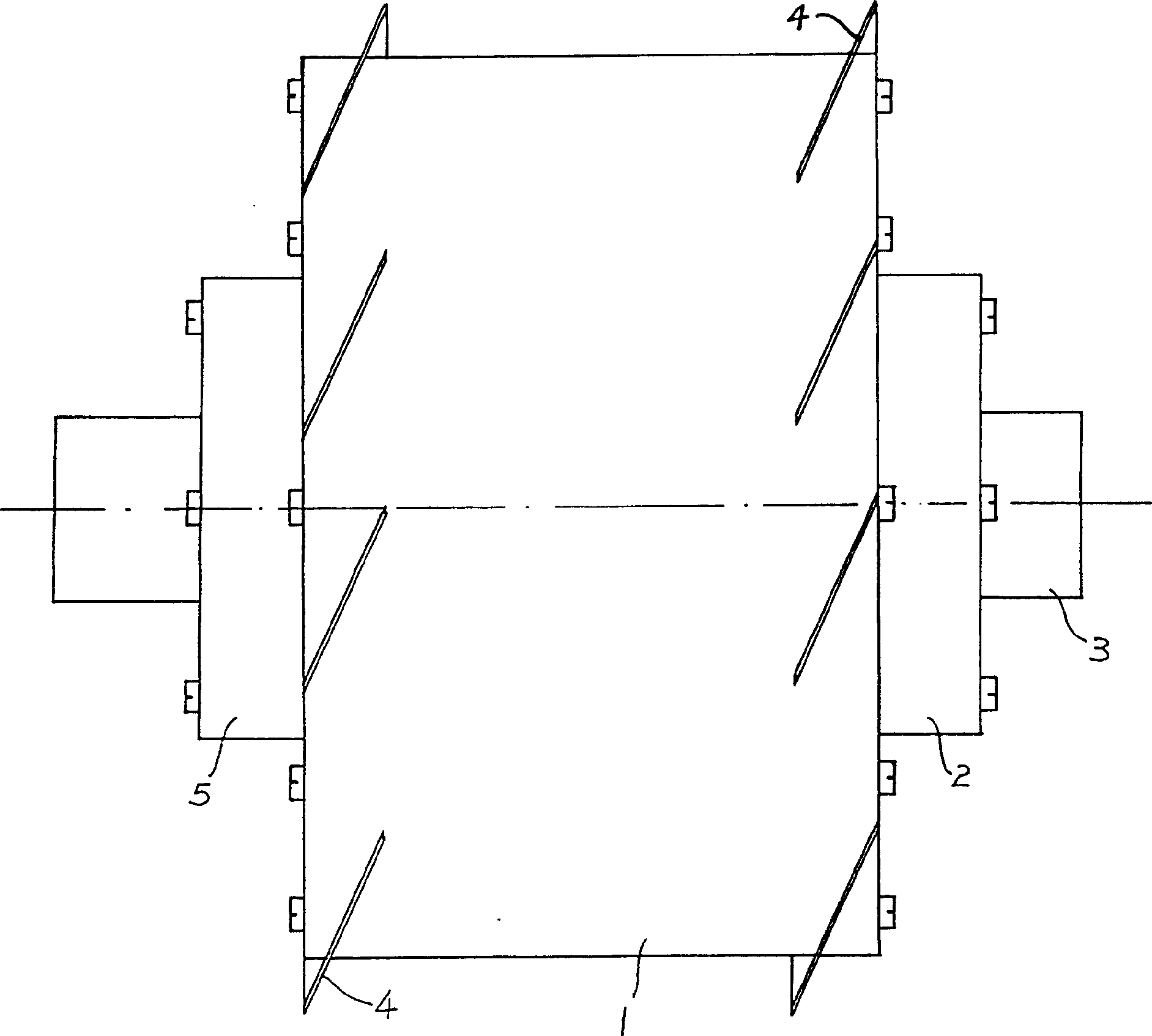

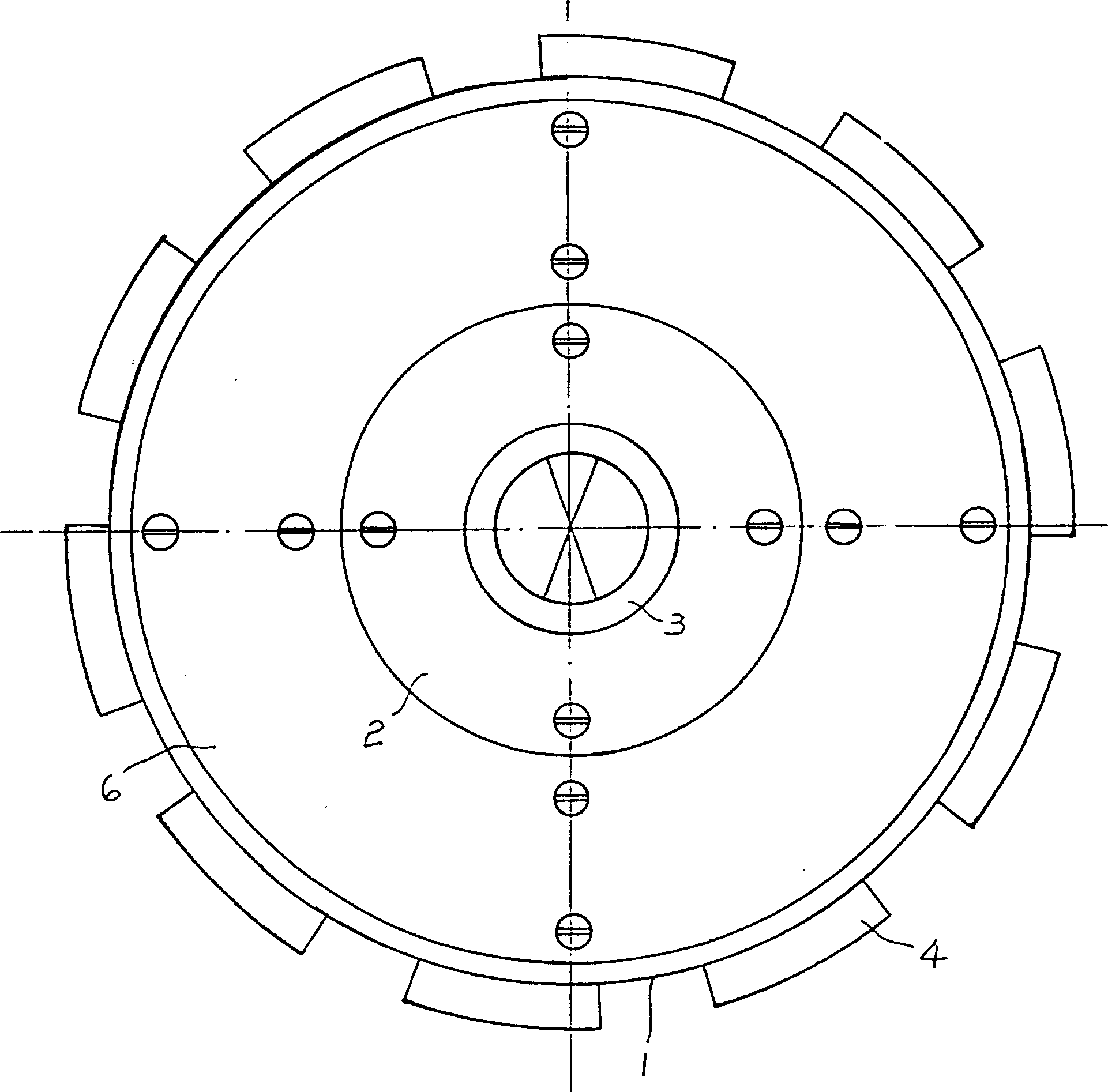

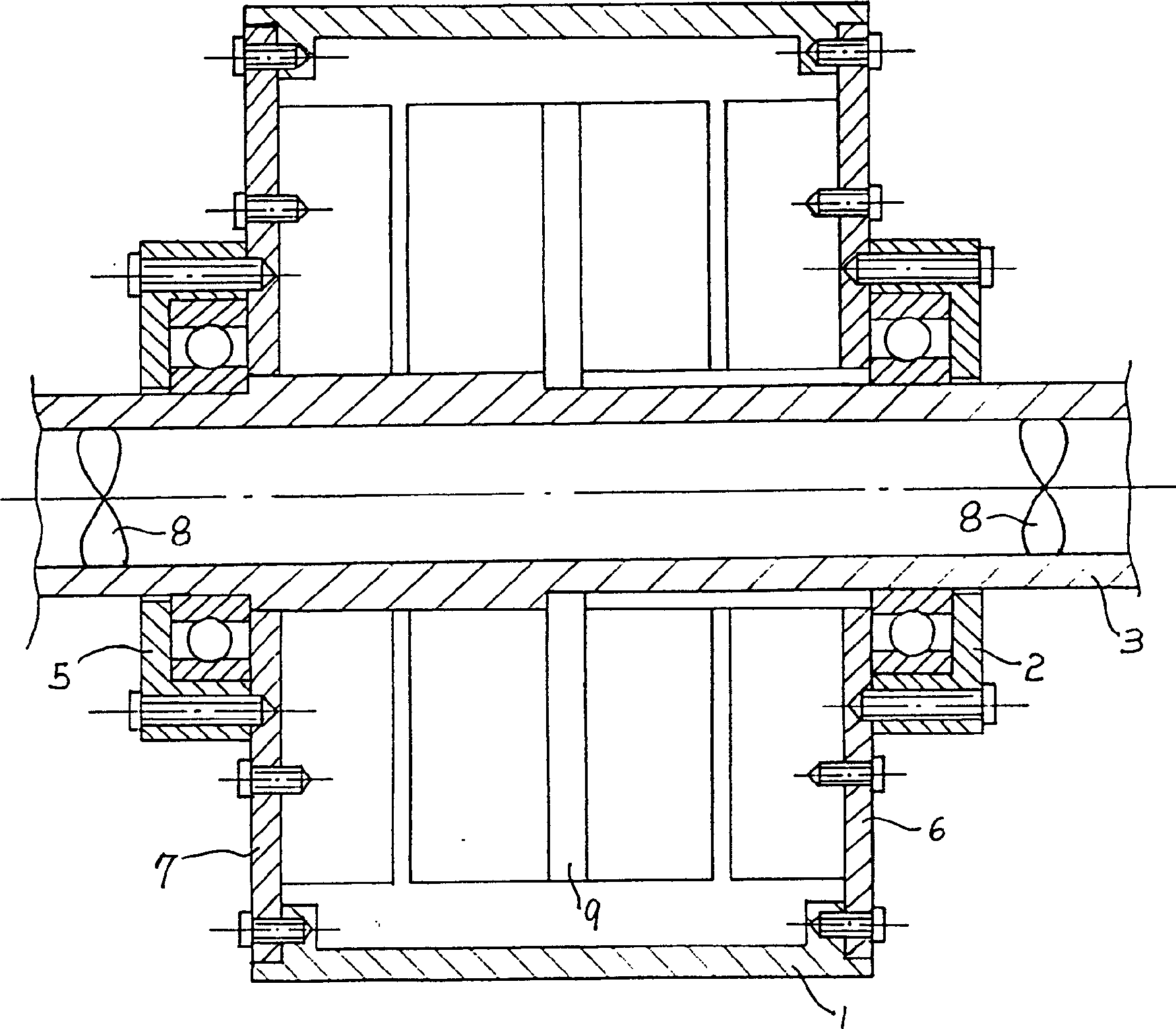

[0029] In the present invention, end caps 6, 7 are fixed at both ends of the cylindrical casing 1, and hollow rotating shafts with cavities are placed on the bearings in the bearing seats 2, 5 fixed with the end caps 6, 7. 3. The fan blade 8 is fixed in the cavity of the rotating shaft 3, the metal ring 9 is fixedly connected to the rotating shaft 3, and the fan blade 4 is placed on the outer surface of the shell of the casing 1. Inside the casing 1 A main pole and an armature are juxtaposed, and the main pole and the armature are respectively fixed on the inner side surfaces of the end caps 6, 7 and both sides on the metal ring 9 and arranged parallel to each other along the axial direction.

[0030] Figure 4 Shown is the first form of motor. Its main pole and armature iron core are fixed on the inner side of the end caps 6, 7 and are formed by radially stacking silicon steel sheets. The inner side has a radial pear-shaped groove on the ring-shaped silicon steel reel 10, 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com