Clamp connector with improved structure for accumulator of car

A car battery and chuck technology, applied in structural parts, circuits, electrical components, etc., can solve the problems of difficult locking and matching construction, damaged threads of locking screws, discounts in electrical conductivity, etc. Efficiency, size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

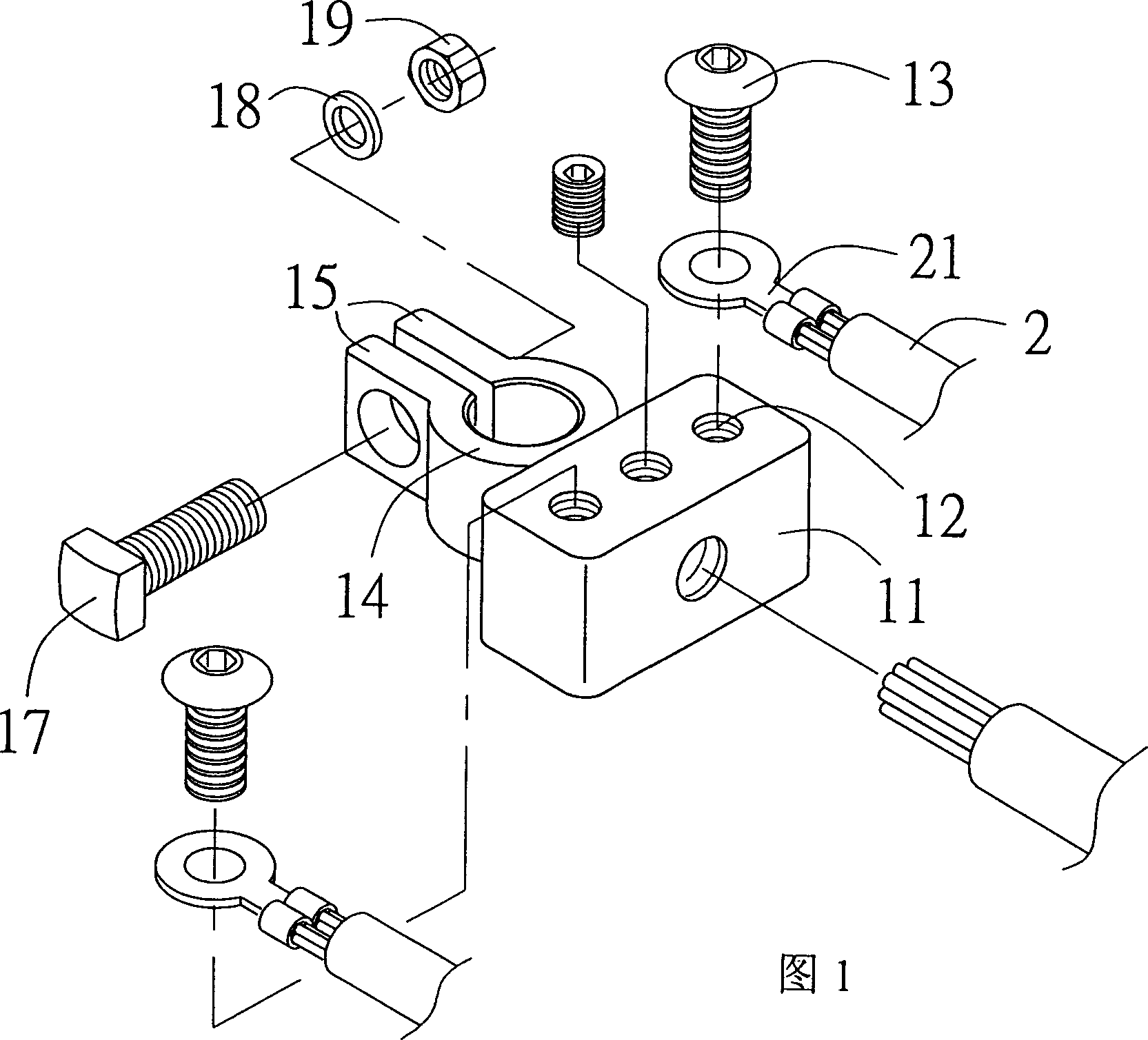

Embodiment Construction

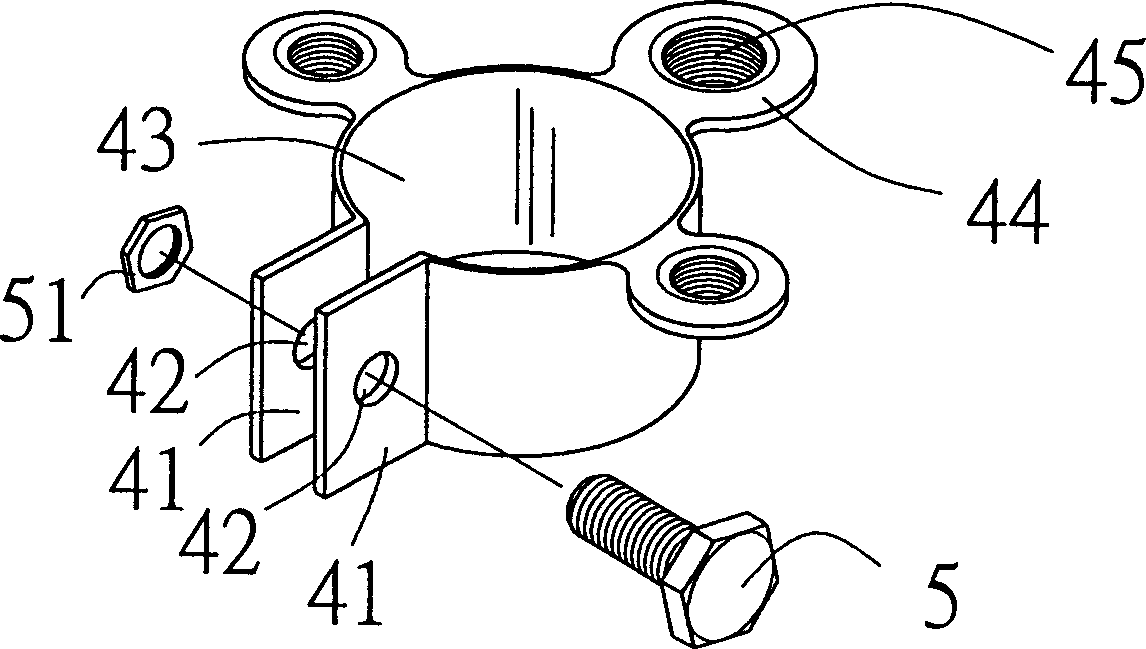

[0045] see image 3 As shown, in the present invention, a beam clamping body 4 is formed into a ring shape by an appropriate processing method, and a beam clamping guide piece 41 is extended and folded on both sides of the beam clamping body 4, and the beam clamping guide piece 41 There is a through hole 42 in the upper mirror, so that there is a gap 43 between the two sides, and the through hole 42 of the clamp guide piece 41 is penetrated by the clamp screw 5, and the clamp screw 5 is engaged with the clamp nut 51 The depth of the clamping body 4 and the displacement between the notch 43 on both sides of the clamping body 4 make the flexible clamping piece 4 produce the effect of clamping or loosening the power connector 31 of the battery 3 (see Figure 4 shown);

[0046] The upper edge of the clamp body 4 is provided with one or more wire fixing pieces (screw lock type) 44, and the wire fixing pieces (screw lock type) 44 are provided with one or more end lock screw holes 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com