Acceleration cavity and accelerator

A technology for accelerating chambers and shells, applied in the field of accelerating chambers and accelerators, can solve the problems of not being able to improve the Q value, and achieve the effect of improving the Q value and improving power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

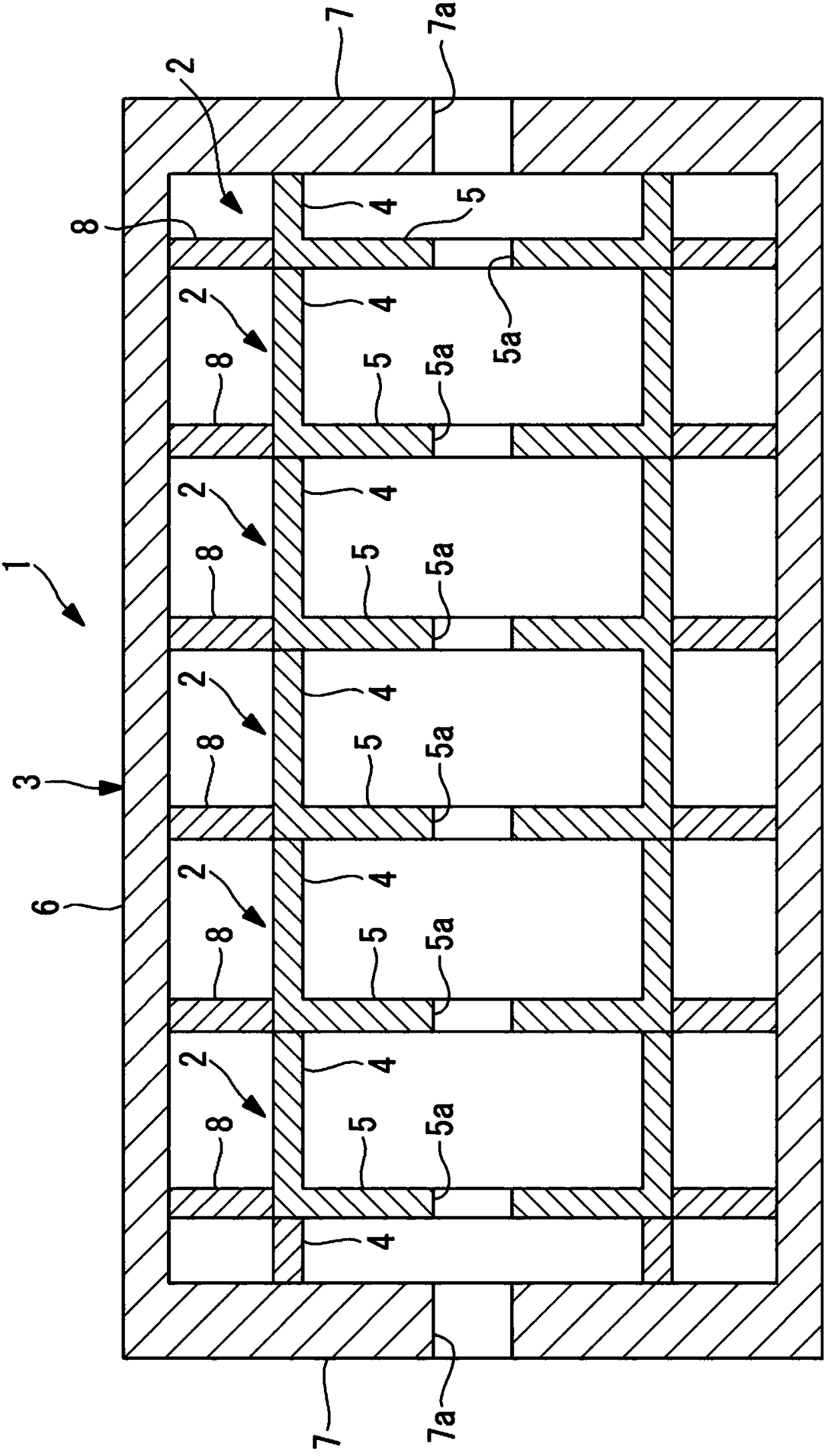

[0037] Below, use figure 1 The accelerator according to the first embodiment of the present invention will be described. figure 1 It is a longitudinal sectional view showing the high-frequency acceleration cavity according to the first embodiment of the present invention.

[0038] The accelerator involved in this embodiment has a high-frequency acceleration chamber 1, and the high-frequency acceleration chamber 1 will be referred to as TM 0n The higher-order mode of the mode (n>1) is used as the acceleration mode.

[0039] The high-frequency acceleration chamber 1 includes a plurality of acceleration units 2 including a dielectric, a cylindrical case 3 in which the plurality of acceleration units 2 are arranged, and the like. For the high-frequency acceleration cavity 1, charged particles pass on the central axis.

[0040] A plurality of acceleration units 2 are arranged in series in the beam axis direction from one end plate 7 of the housing 3 to the other end plate 7 insi...

no. 2 Embodiment approach

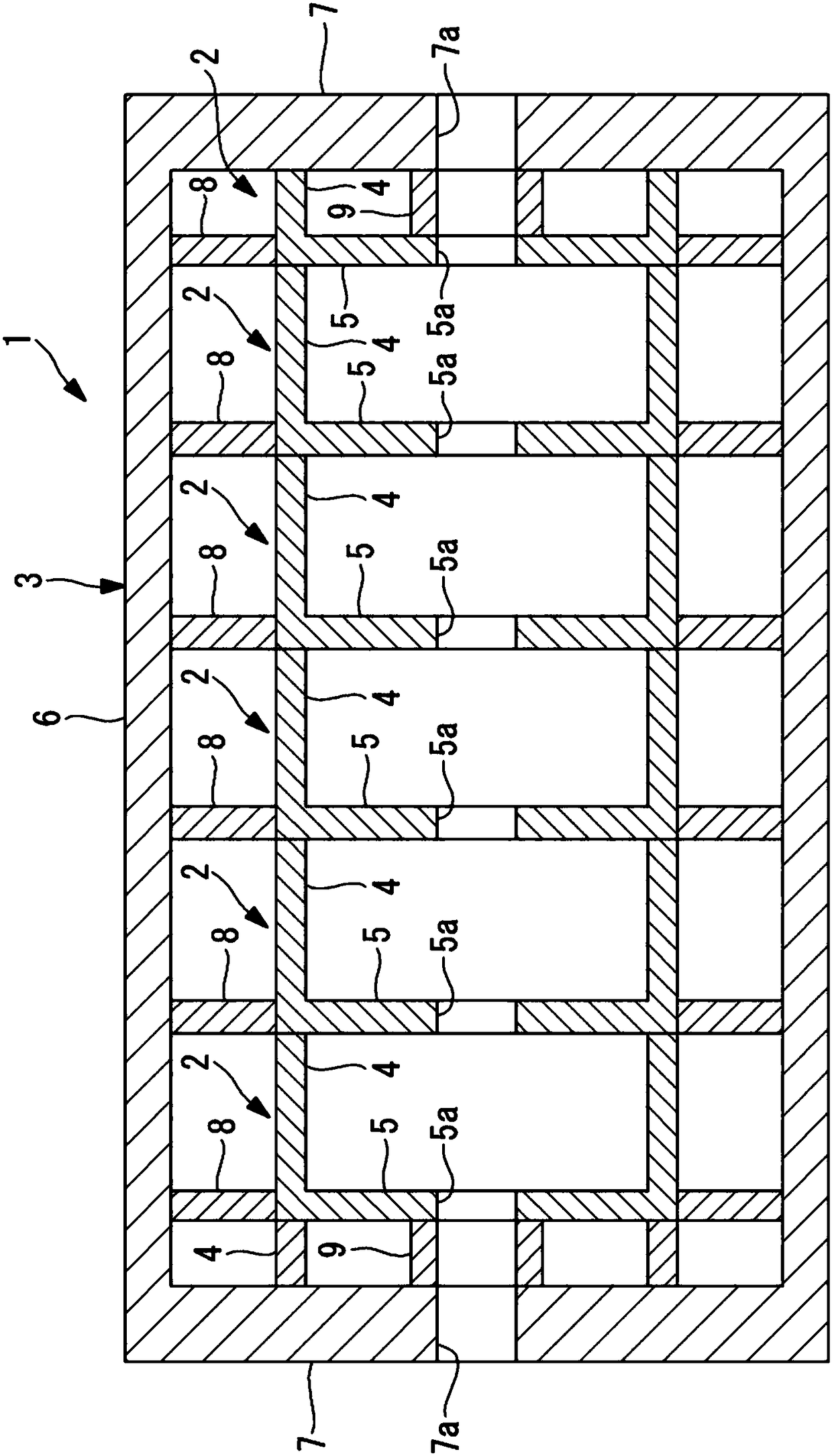

[0061] Next, use image 3 The radio-frequency acceleration chamber 1 according to the second embodiment of the present invention will be described. In the radio-frequency acceleration chamber 1 according to the present embodiment, the acceleration unit 2 adjacent to the end plate 7 of the case 3 among the acceleration units 2 is provided with a cylindrical portion 9 around the beam axis. In addition, the cylindrical portion 9 is provided on the acceleration unit 2 near the end plates 7 on both sides. The cylindrical portion 9 has the same inner diameter as the opening 5 a of the disk portion 5 , one end is connected to the end plate 7 of the case 3 , and the other end is connected to the disk portion 5 of the acceleration unit 2 .

[0062] The cylindrical portion 9 is the same dielectric material as the cylindrical portion 4 , the disc portion 5 , and the annular portion 8 described in the first embodiment.

[0063] In the first embodiment, the high-frequency magnetic field ...

no. 3 Embodiment approach

[0066] Next, use Figure 4 The radio-frequency acceleration chamber 1 according to the third embodiment of the present invention will be described. In the high-frequency acceleration chamber 1 according to the present embodiment, a plurality of cylindrical portions 4 with different diameters are concentrically arranged in one acceleration unit 2 . Accordingly, the high-frequency acceleration cavity 1 can use higher-order modes in the acceleration mode. In addition, as a result, the Q value can be further improved.

[0067] In the first embodiment, the case where only one cylindrical portion 4 is provided in each acceleration unit 2 has been described, but the present invention is not limited to this example. Two or more cylindrical parts 4 may be provided. exist Figure 4 In , an example in which two cylindrical parts 4 are provided is shown.

[0068] When two or more cylindrical parts 4 are provided, the central axes of the respective cylindrical parts 4 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com