Mechanical vehicle ray camera testing systems

A radiographic and detection system technology, applied in the field of radiographic detection, can solve the problems of units such as modulators with heavy weight, frequent plugging and unplugging, difficult operation, etc., achieve large detection range and detection ability, reduce dependence on site conditions, and adapt to the environment good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

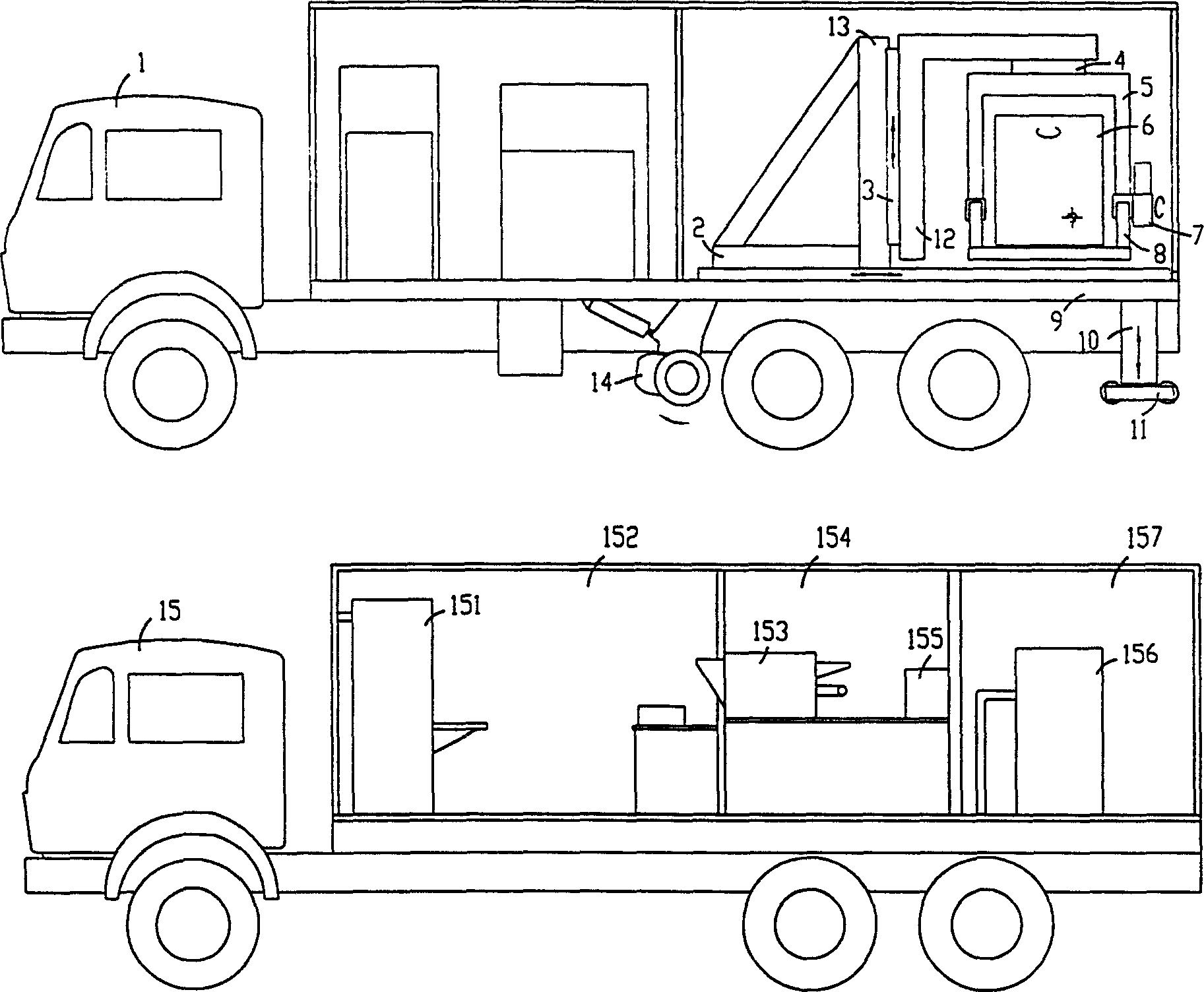

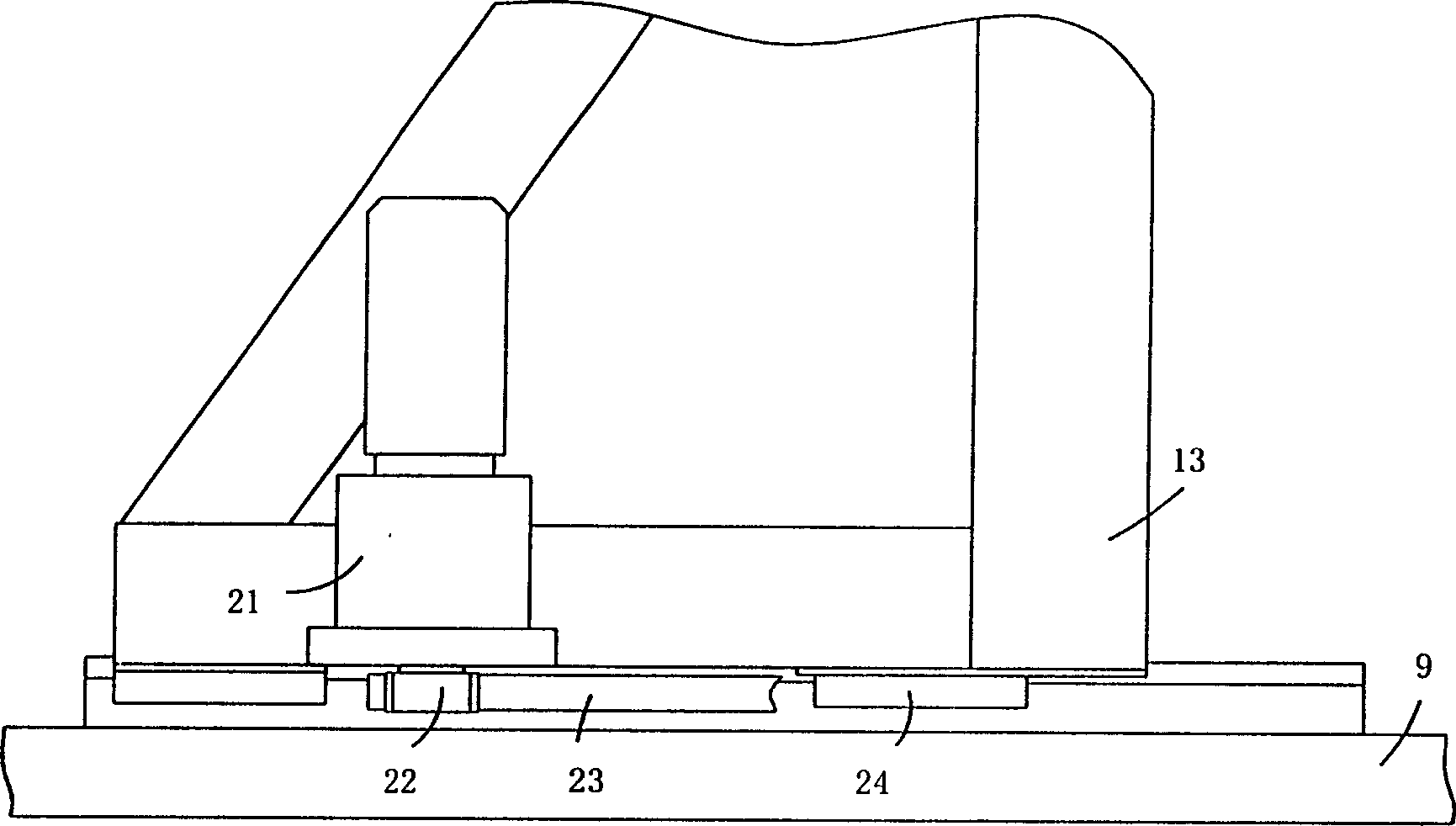

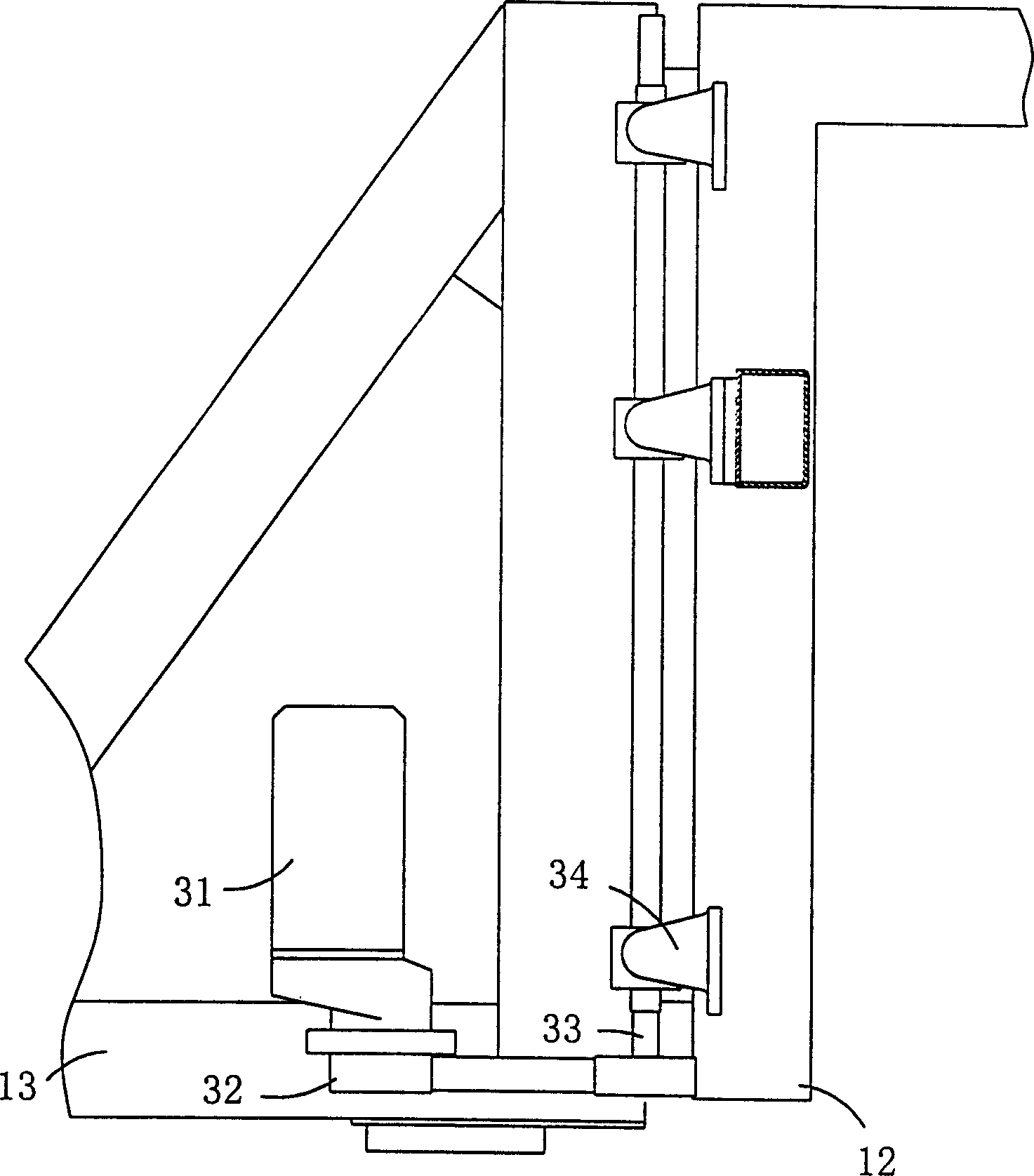

[0025] see figure 1 , the vehicle-mounted mobile radiography detection system includes an accelerator 6 , a detection vehicle 1 and a control vehicle 15 . The ancillary equipment of the accelerator and the control equipment of the system are arranged in the front cabin of the inspection vehicle 1 . A bracket 9 is arranged in the back compartment of the inspection vehicle 1, and the telescopic device 2 is installed on the bracket 9 to make the mobile frame made up of the fixed mount 13 and the frame 12 move back and forth horizontally. A lifting device 3 is installed between the fixed frame 13 and the frame 12 to make the frame 12 move up and down. A support consisting of an upper support 5 and a lower support 8 is installed in the frame 12. A rotating device 4 is installed between the end face of the frame 12 and the upper support 5 to make the support rotate as a whole. An accelerator 6 is installed on the lower support 8, and the upper support 5 and the lower support 8 is ...

Embodiment approach 2

[0037] When light-weight radioactive sources such as small electron accelerators, X-ray machines or gamma sources are used, the previously mentioned contraction device may not be installed on the inspection vehicle. Other implementations are the same as the first implementation.

Embodiment approach 3

[0039] This embodiment is basically the same as the first embodiment, except that the control car is removed. The control equipment on the aforementioned control vehicle is stored on the testing vehicle, and taken out from the testing vehicle when in use, the operation of the remote control accelerator, and the equipment layout on the testing vehicle are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com